Electronics & Semiconductors

-

Electronics industry

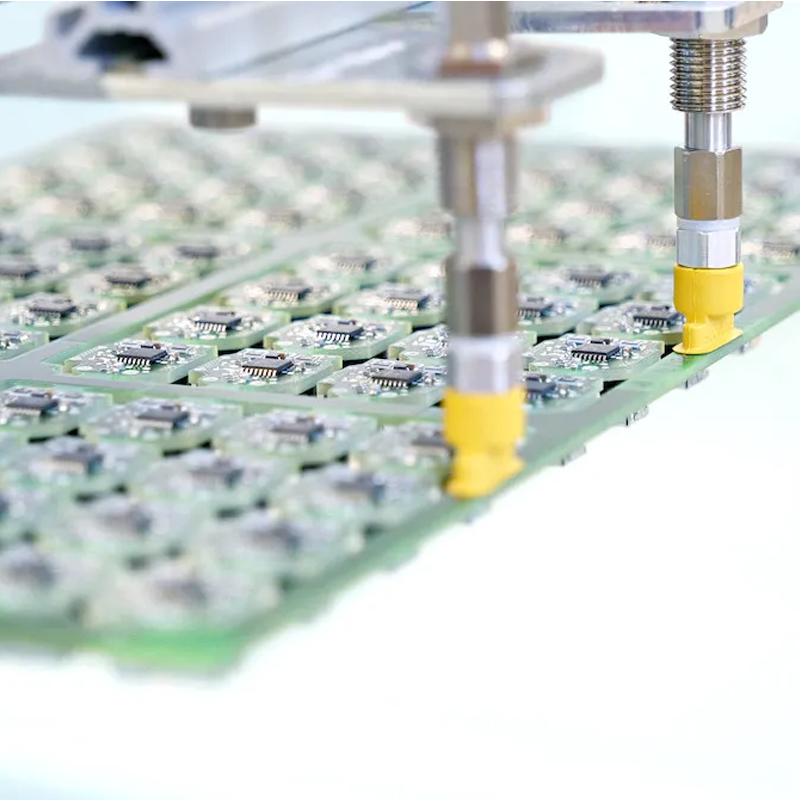

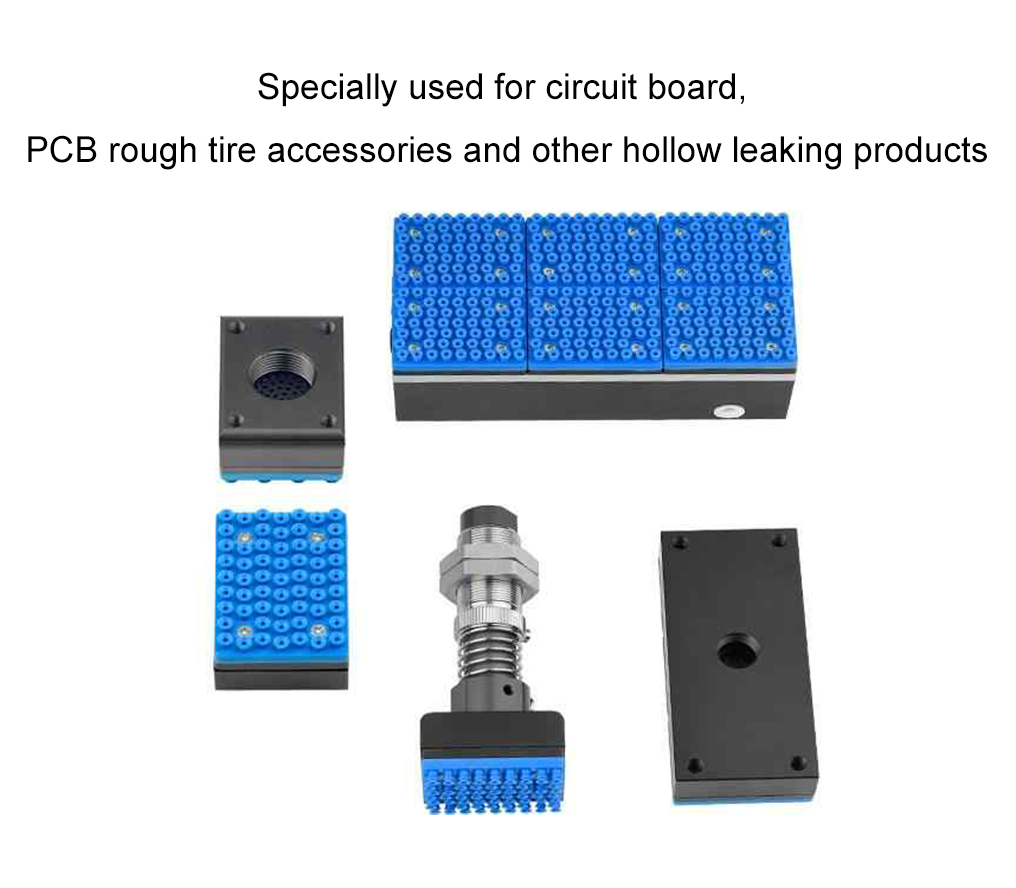

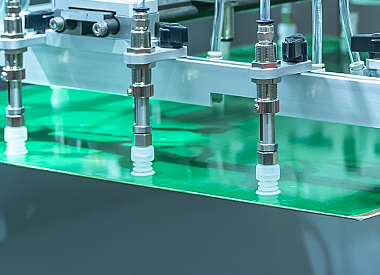

2023/11/09The inherent characteristics of circuit boards are porous and manufacturers need to change shapes frequently, and even if the traditional small suction cups can be coordinated, they need to change the scheme frequently due to the complex changes of holes....

-

Case Study: How a Semiconductor PCB Maker Cut Scrap by 89% with Integrated Vacuum Suction Cups

2025/08/22 Client Profile: A U.S.-based semiconductor component manufacturer specializing in high-frequency PCBs for 5G base stations and data center servers. The client produces 12,000 PCBs daily—including ultra-thin flex circuits (0.15mm thick) and H...

-

Case Study: How a Smart Wearable Component Maker Cut Part Damage by 92% with [Company Name]’s Mini Fixtures

2025/08/21Case Study: How a Smart Wearable Component Manufacturer Reduced Part Damage by 92% Using Microgrippers Customer Profile: A leading US contract manufacturer specializing in components for smartwatches and fitness trackers. The customer produces 5 mill...

-

Improving the assembly precision of electronic components: the key role of pneumatic suction cups

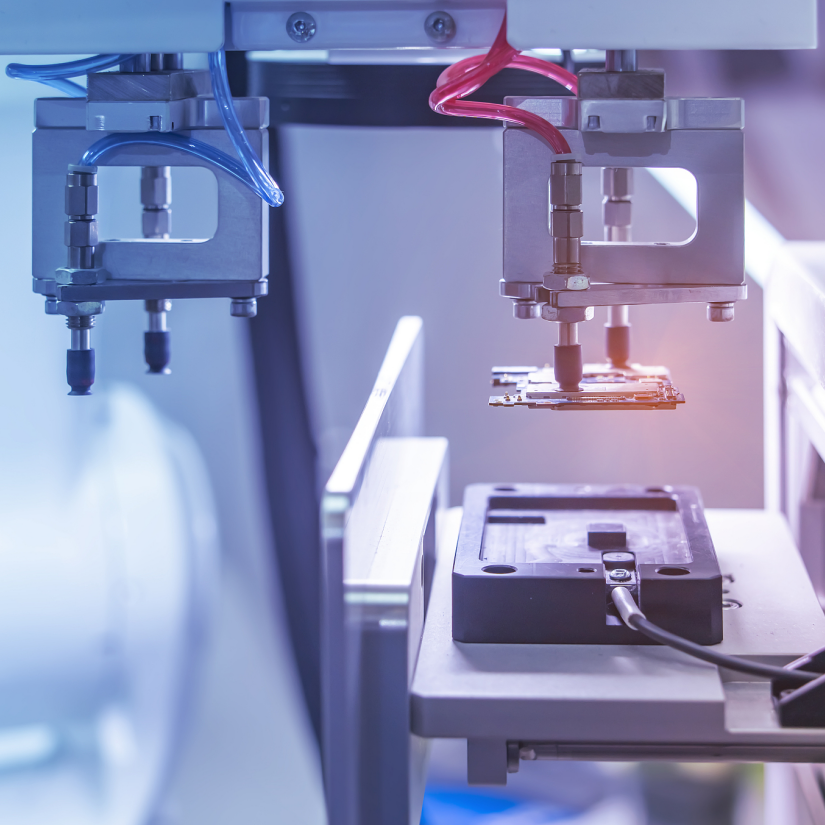

2025/08/14August 14, 2025, with the growing demand for precision assembly in the electronics manufacturing industry, pneumatic suction cup technology has become a key tool for improving assembly precision. At the Global Electronic Manufacturing Technology Foru...

-

Vacuum pneumatic chuck: "sub-micron" precision tool for semiconductor manufacturing

2025/05/30The global chip industry faces the dual challenges of wafer thinning limit (3nm process thickness ≈ 0.1mm) and yield improvement bottleneck (defect density needs to be <0.01/cm²). Traditional robo...