Case Study: How a Smart Wearable Component Maker Cut Part Damage by 92% with [Company Name]’s Mini Fixtures

Case Study: How a Smart Wearable Component Manufacturer Reduced Part Damage by 92% Using Microgrippers

Customer Profile: A leading US contract manufacturer specializing in components for smartwatches and fitness trackers. The customer produces 5 million micro parts annually (e.g., 3-15 mm PCB connectors, thin plastic display frames, and coated sensor housings).

Challenge: Small, delicate parts were prone to breakage, slowing production.

Prior to this collaboration, the customer struggled to automate the handling of their smallest, most fragile components. Their reliance on standard microgrippers and general-purpose vacuum tools led to three key issues:

1. Catastrophic Part Damage

Thin plastic display frames (0.8 mm thick) and coated sensor housings would be scratched or crushed by standard metal grippers, resulting in a damage rate as high as 12% (60,000 defective parts per month) and $48,000 in material waste.

2. Unreliable gripping of micro connectors

3mm micro PCB connectors (used in smartwatch batteries) would slip off a standard vacuum tool during transfer, causing over eight line stops per shift (45 minutes of downtime per day) and missing production targets.

3. Poor adaptability to irregular shapes

Irregularly sized plastic fasteners (5-10mm) required manual adjustment to the narrow-mouthed clamp, adding two minutes to each batch and slowing the assembly line by 18%.

"Our components were getting smaller every year, but standard tooling couldn't keep up," said the Director of Customer Operations. "We either use too much force, which breaks the part, or too little grip, which causes it to get lost—a lose-lose situation."

Solution: Intelligent Robotics' three-piece microgripper set—tailored for micro needs

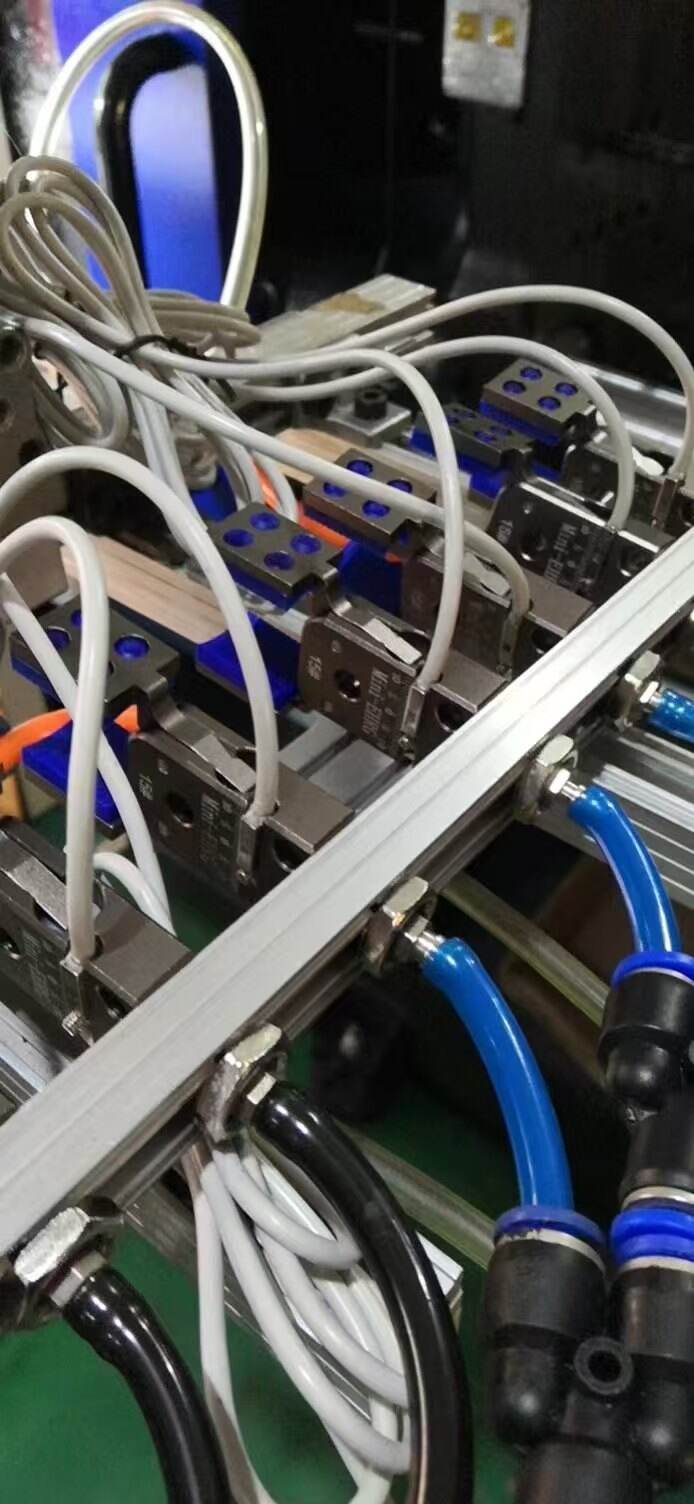

After reviewing the customer's assembly line and testing its key components, we recommended a solution consisting of three products, each addressing a specific pain point:

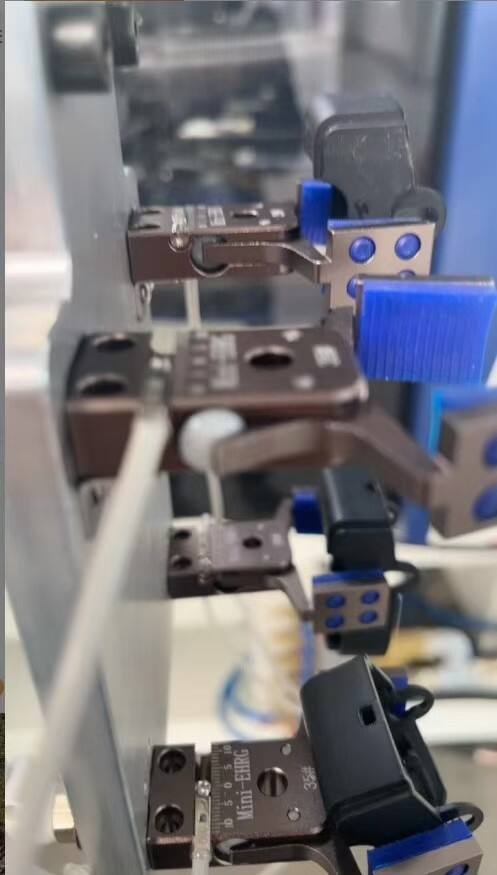

1. Vacuum Microgripper for Micro Connectors

To address the issue of 3mm PCB connectors slipping, we deployed a vacuum microgripper—an ultra-compact (15mm × 10mm) tool with adjustable low-pressure suction (5 kPa) for a secure hold without damaging delicate pins. Key customizations:

A 2mm diameter suction cup (which conforms to the top surface of the connector) eliminates pin contact obstruction.

Integrated with the customer's existing Yamaha YSM20 pick-and-place robot (no line reconfiguration required).

2. Silicone-pad pneumatic grippers for fragile frames

For thin plastic display frames and coated sensor housings, silicone-pad pneumatic grippers replace metal grippers. The food-grade silicone pad (3 mm thick) conforms to the part surface and eliminates scratches, while the double-action drive (0.2-second response time) meets the demands of high-speed production lines.

3. Pneumatic wide and small grippers for irregular fasteners

To reduce manual adjustment time for irregular fasteners, the pneumatic wide and small grippers (with a 12 mm jaw width, three times wider than standard mini grippers) provide the flexibility to grip fasteners ranging from 5-10 mm in size. Quick-change jaw inserts (plastic for soft parts, metal for hard parts) enable customers to switch batches in just 30 seconds.

Results: 92% reduction in damage, 28% increase in production speed

Within three weeks of full implementation, the customer experienced significant operational improvements:

"From day one, the vacuum microgripper hasn't dropped a single connector," said [Mike Lee]. "And the silicone grippers? We used to have to pick out one intact frame out of 10—now there's barely a scratch. We were even able to reassign two operators who were reworking the system to other lines."

Long-term, the customer expects to save $532,800 annually through reduced waste and downtime, achieving a full return on investment (ROI) in just 2.7 months.

Reason for Success: Precision, not a "one-size-fits-all" approach

The success of this collaboration hinges on two key factors:

Part-specific design: Instead of using generic tooling, we tailor each gripper's size, suction force, and gripping material to the customer's specific part (e.g., 2mm suction cups for connectors, silicone pads for frames).

Seamless Integration: All grippers work with customers' existing robots and production lines, eliminating costly downtime due to reconfiguration.

Ready to solve your microgripping challenges?

This smart wearable device manufacturer proves that small parts don't have to mean big problems. Whether you're working with 3mm electronics, thin plastics, or irregular components, our line of mini grippers provides precision, protection, and speed.

Next Steps:

Request a free component test (we'll test your part with the grippers and share the results).

View