Other cases

-

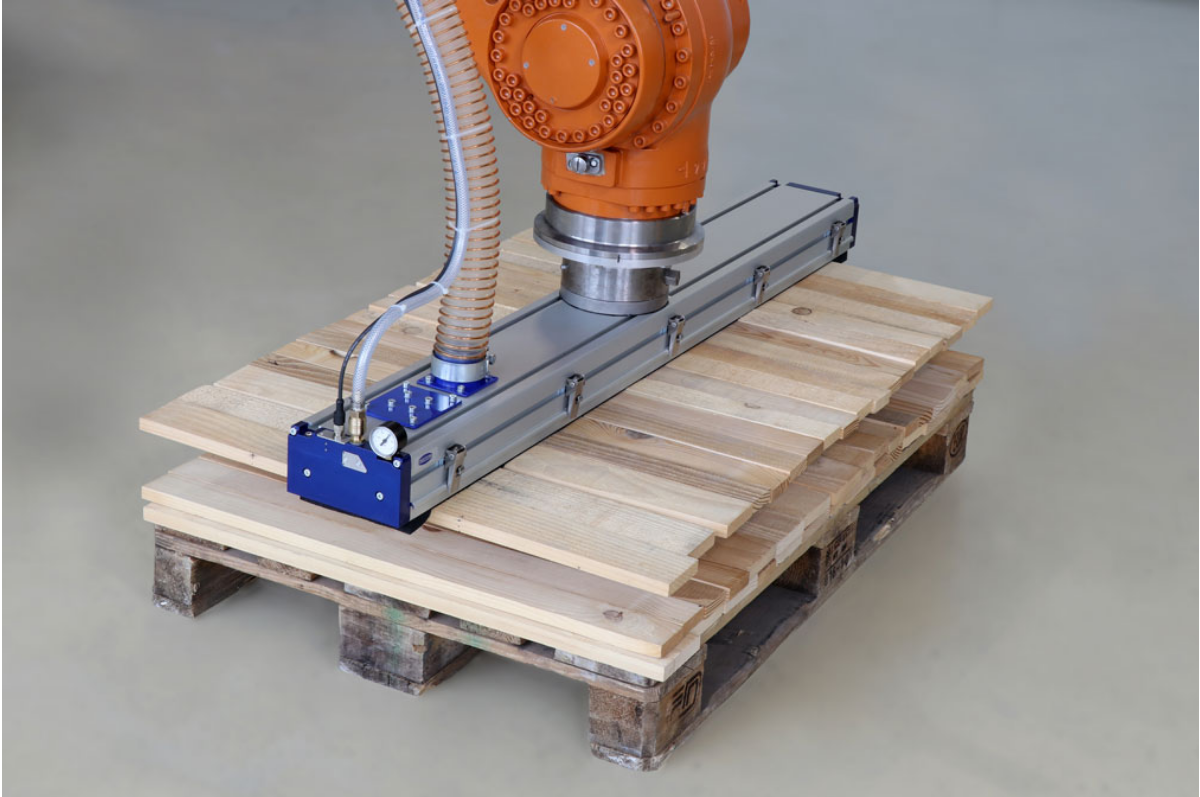

Real-World Success: How Width-Integrated Vacuum Sponge Suction Cups Transform Handling for Cartons, Steel & Wood

2025/08/28For manufacturers and logistics teams, robotic handling inefficiencies aren’t just inconvenient—they’re costly. Leaky external vacuum systems, scratched workpieces, and constant tool swaps eat into productivity and profit. Our ...

-

How the 130-Series Integrated Vacuum Suction Cups Transform Robotic Handling for Cartons, Steel & Wood

2025/08/28For manufacturers and logistics teams relying on heavy-duty robotic arms, inefficient suction tools often mean one thing: lost time and money. Leaky external vacuum systems slow down palletizing, rigid cups scratch valuable loads, and one-size-fits-a...

-

Real-World Applications: How 60 & 80mm-Wide Integrated Vacuum Sponge Suction Cups Transform Robotic Handling Across 3 Industries

2025/08/26For manufacturers and logistics teams, robotic arm efficiency lives or dies by the suction cup. When traditional tools fail—leaking on rough steel, clogging with wood dust, or scratching cartons—productivity plummets. Our 60 & 80...

-

Industry Applications: How ZP Heavy-Duty Sponge Suction Cups Solve Handling Challenges Across 6 Sectors

2025/08/25Heavy-duty material handling looks different across industries—but one thing stays the same: the need for reliable, damage-free gripping. Our ZP Heavy-Duty Sponge Suction Cups—with their leak-proof connections, smooth surfaces, and high-e...

-

Case Studies: How 200mm-Wide Integrated Vacuum Suction Cups Transform 6 Key Industries

2025/08/23Case Studies: How 200mm-Wide Integrated Vacuum Suction Cups Transform 6 Key Industries For manufacturers and logistics teams, the right material handling tool doesn’t just save time—it protects brand reputation, cuts scrap costs, and unl...

-

# EOAT Frame Connectors: Integrating Pneumatic Grippers and Robotic Arms in Automated Workshops

2025/08/18In the era of Industry 4.0, automated workshops are undergoing a transformative shift towards greater efficiency, precision, and flexibility. At the heart of this evolution lies the seamless integration of end-of-arm tooling (EOAT) systems, where fra...

-

Pneumatic Scissors: The Ultimate Solution for Plastic Flash Trimming in Injection Molding Shops

2025/08/16Injection molding is a cornerstone of plastic manufacturing, but one persistent challenge plagues every shop floor: plastic flash. This excess material—formed when molten plastic seeps into gaps between mold halves—ruins product aestheti...

-

New CV vacuum generator improves industrial automation efficiency

2025/08/14Date: March 2025 In the field of modern industrial automation, CV vacuum generators have attracted much attention due to their high efficiency and stable performance. The newly developed CV vacuum generator adopts an advanced nozzle design, wh...

-

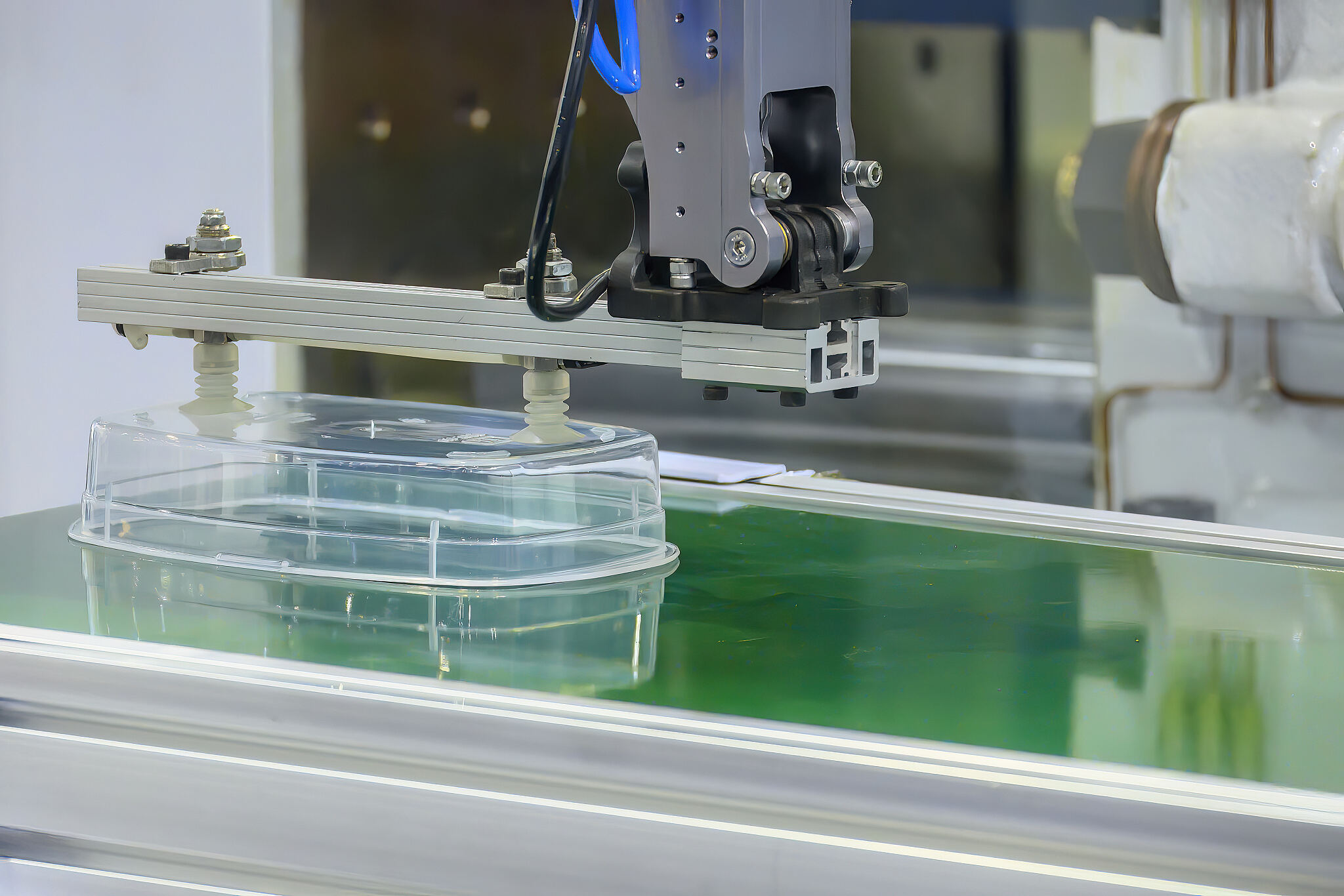

Efficient and traceless handling: vacuum pneumatic suction cups reshape the automated injection molding production chain

2025/06/02Amid the wave of manufacturing upgrades in Europe, America, and Southeast Asia, the injection molding industry faces a core challenge: how to achieve zero-damage, high-speed transportation of plastic parts from molds to finished products. Tra...