INDUSTRY CASE CENTER

-

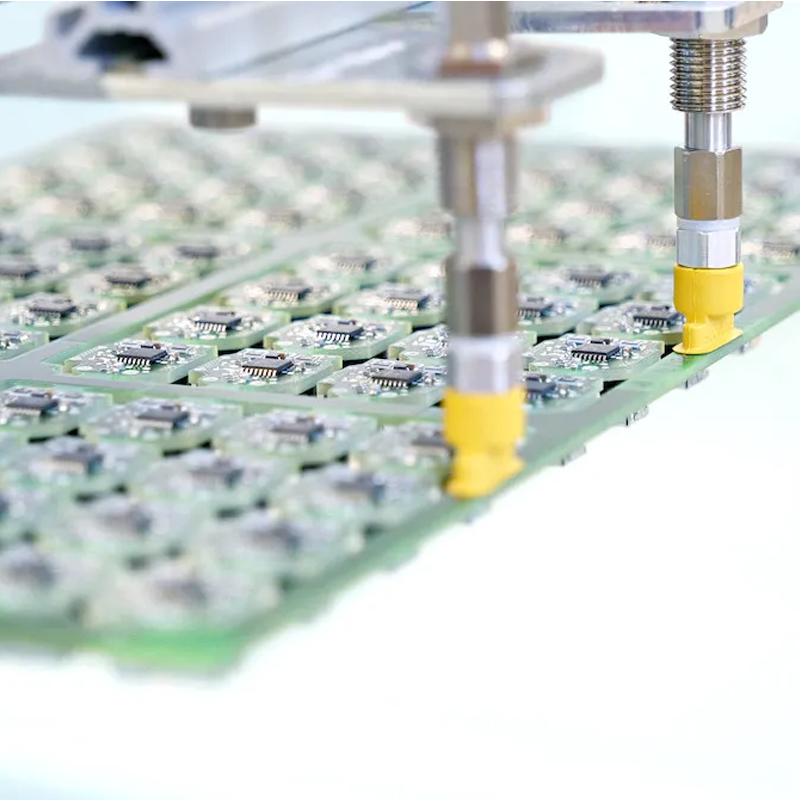

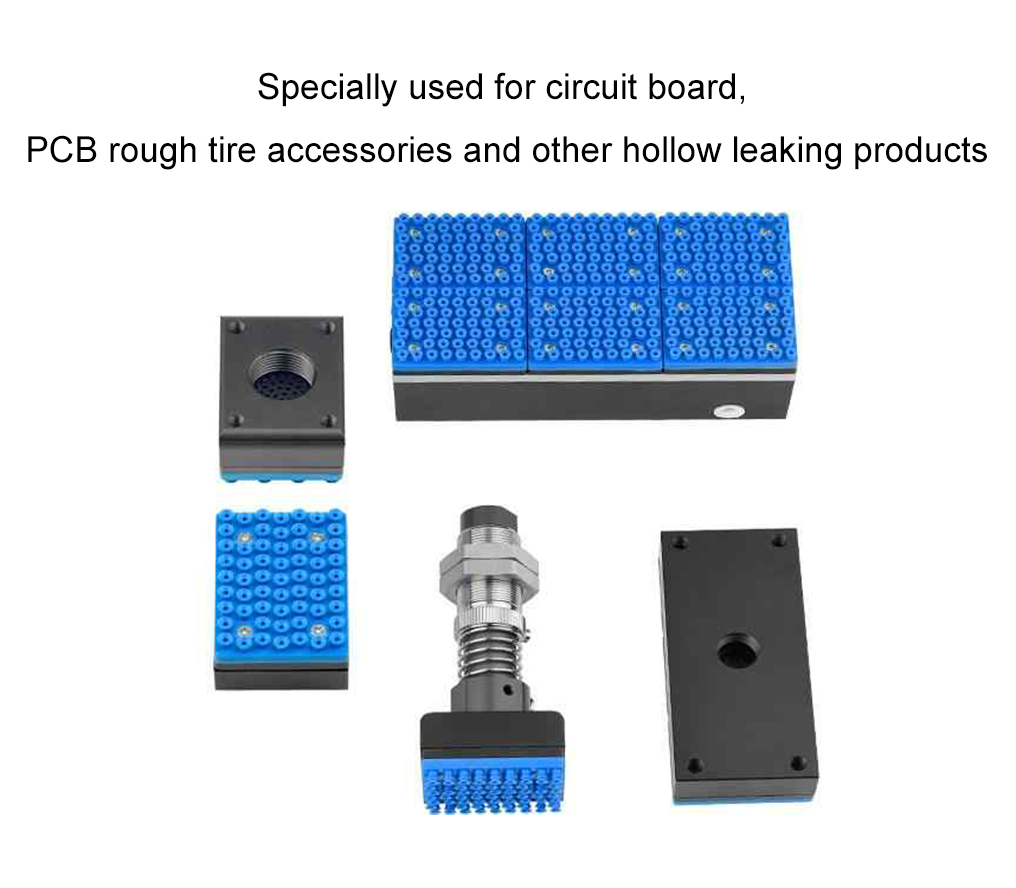

Electronics industry

2023/11/09The inherent characteristics of circuit boards are porous and manufacturers need to change shapes frequently, and even if the traditional small suction cups can be coordinated, they need to change the scheme frequently due to the complex changes of holes....

-

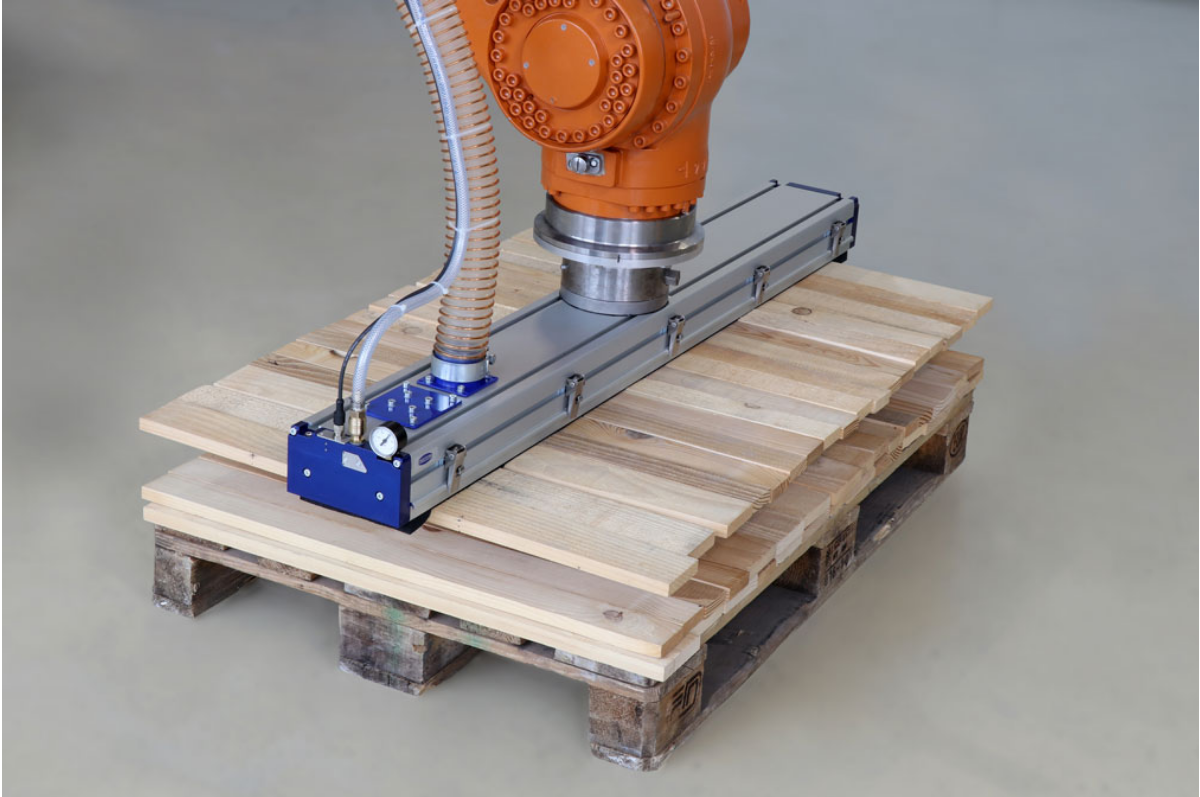

Real-World Success: How Width-Integrated Vacuum Sponge Suction Cups Transform Handling for Cartons, Steel & Wood

2025/08/28For manufacturers and logistics teams, robotic handling inefficiencies aren’t just inconvenient—they’re costly. Leaky external vacuum systems, scratched workpieces, and constant tool swaps eat into productivity and profit. Our ...

-

How the 130-Series Integrated Vacuum Suction Cups Transform Robotic Handling for Cartons, Steel & Wood

2025/08/28For manufacturers and logistics teams relying on heavy-duty robotic arms, inefficient suction tools often mean one thing: lost time and money. Leaky external vacuum systems slow down palletizing, rigid cups scratch valuable loads, and one-size-fits-a...

-

Real-World Applications: How 60 & 80mm-Wide Integrated Vacuum Sponge Suction Cups Transform Robotic Handling Across 3 Industries

2025/08/26For manufacturers and logistics teams, robotic arm efficiency lives or dies by the suction cup. When traditional tools fail—leaking on rough steel, clogging with wood dust, or scratching cartons—productivity plummets. Our 60 & 80...

-

Industry Applications: How ZP Heavy-Duty Sponge Suction Cups Solve Handling Challenges Across 6 Sectors

2025/08/25Heavy-duty material handling looks different across industries—but one thing stays the same: the need for reliable, damage-free gripping. Our ZP Heavy-Duty Sponge Suction Cups—with their leak-proof connections, smooth surfaces, and high-e...

-

Case Studies: How 200mm-Wide Integrated Vacuum Suction Cups Transform 6 Key Industries

2025/08/23Case Studies: How 200mm-Wide Integrated Vacuum Suction Cups Transform 6 Key Industries For manufacturers and logistics teams, the right material handling tool doesn’t just save time—it protects brand reputation, cuts scrap costs, and unl...

-

Case Study: How a Semiconductor PCB Maker Cut Scrap by 89% with Integrated Vacuum Suction Cups

2025/08/22 Client Profile: A U.S.-based semiconductor component manufacturer specializing in high-frequency PCBs for 5G base stations and data center servers. The client produces 12,000 PCBs daily—including ultra-thin flex circuits (0.15mm thick) and H...

-

Case Study: How a Smart Wearable Component Maker Cut Part Damage by 92% with [Company Name]’s Mini Fixtures

2025/08/21Case Study: How a Smart Wearable Component Manufacturer Reduced Part Damage by 92% Using Microgrippers Customer Profile: A leading US contract manufacturer specializing in components for smartwatches and fitness trackers. The customer produces 5 mill...

-

Case Study: How a Leading Automotive Plastic Parts Manufacturer Reduced Waste by 40% with Our Internal-Support Vacuum Suction Cups

2025/08/20The Challenge: Perforated Part Handling Was Costing Them Thousands Monthly Prior to partnering with Suzhou Shuowei Automation Technology Co., Ltd., the client faced persistent issues with their automated injection molding line—specifically whe...

-

# EOAT Frame Connectors: Integrating Pneumatic Grippers and Robotic Arms in Automated Workshops

2025/08/18In the era of Industry 4.0, automated workshops are undergoing a transformative shift towards greater efficiency, precision, and flexibility. At the heart of this evolution lies the seamless integration of end-of-arm tooling (EOAT) systems, where fra...