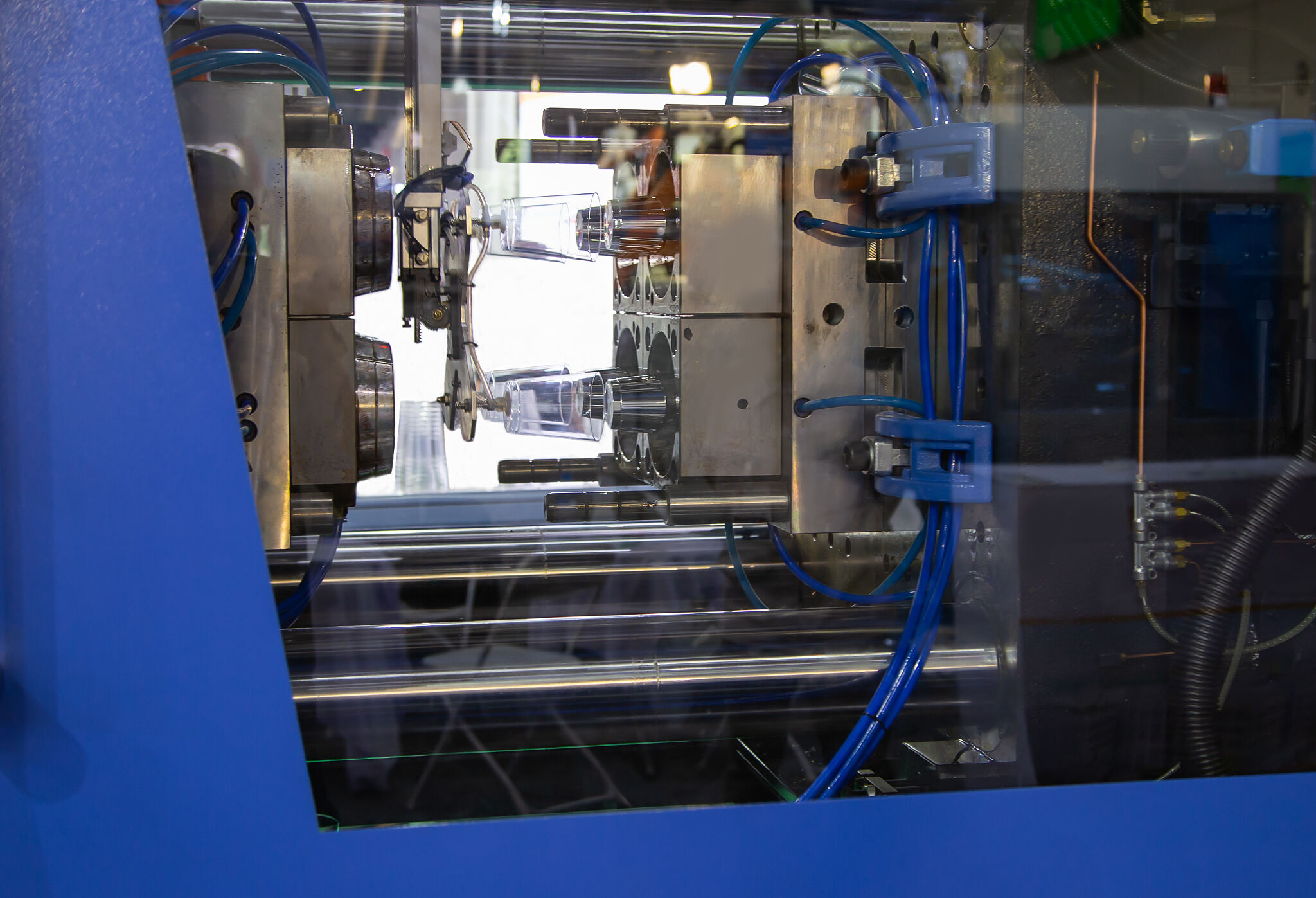

Efficient and traceless handling: vacuum pneumatic suction cups reshape the automated injection molding production chain

Amid the wave of manufacturing upgrades in Europe, America, and Southeast Asia, the injection molding industry faces a core challenge: how to achieve zero-damage, high-speed transportation of plastic parts from molds to finished products. Traditional mechanical grippers are prone to scratches and deformation of parts, and vacuum pneumatic suction cups are becoming a key technology to solve this pain point.

▶ German case: BMW Leipzig plant uses Φ50mm high-temperature resistant suction cups (230℃) to remove bumper injection molded parts within 3 seconds, avoiding shrinkage defects caused by traditional grippers.

▶ Southeast Asian practice: A Japanese-funded company in Thailand achieved non-destructive removal of thin-walled (0.8mm) cosmetic packaging bottles, and the yield rate increased by 31%.

▶ Vietnam success case: Food container manufacturers use a suction cup matrix system to simultaneously transfer 24 lunch boxes to printing stations, saving labor costs of $ 15,800/month.

Cost optimization breakthrough:

▶Philippines project: Using modular suction cup groups, the production change time is reduced to 1/6 of the traditional system.

▶Malaysia practice: Solar panel bracket injection molded parts handling, ROI cycle shortened to 8.2 months.

Technology evolution trend:

▶Intelligent perception fusion: Integrated AI visual positioning system (such as Singapore ST Engineering solution).

▶Ultra-lightweight design: Carbon fiber suction cup arm reduces weight by 40% (result of EU H2020 plan).

▶Self-cleaning function: Anti-adhesion coating for humid environments in Southeast Asia.

Vacuum pneumatic suction cup is not only a tool innovation, but also a strategic fulcrum for the upgrading of the injection molding industry. For European and American companies pursuing zero-defect production, or Southeast Asian factories that urgently need to reduce costs and increase efficiency, this technology has proven its cross-scenario adaptability - the practice of the Ho Chi Minh City Industrial Park in Vietnam shows that after adopting the vacuum adsorption system, the secondary damage rate of injection molded parts has dropped to 0.003%.