Improving the assembly precision of electronic components: the key role of pneumatic suction cups

August 14, 2025, with the growing demand for precision assembly in the electronics manufacturing industry, pneumatic suction cup technology has become a key tool for improving assembly precision. At the Global Electronic Manufacturing Technology Forum held recently, experts agreed that pneumatic suction cups play an irreplaceable role in the grasping, positioning, and assembly of microelectronic components.

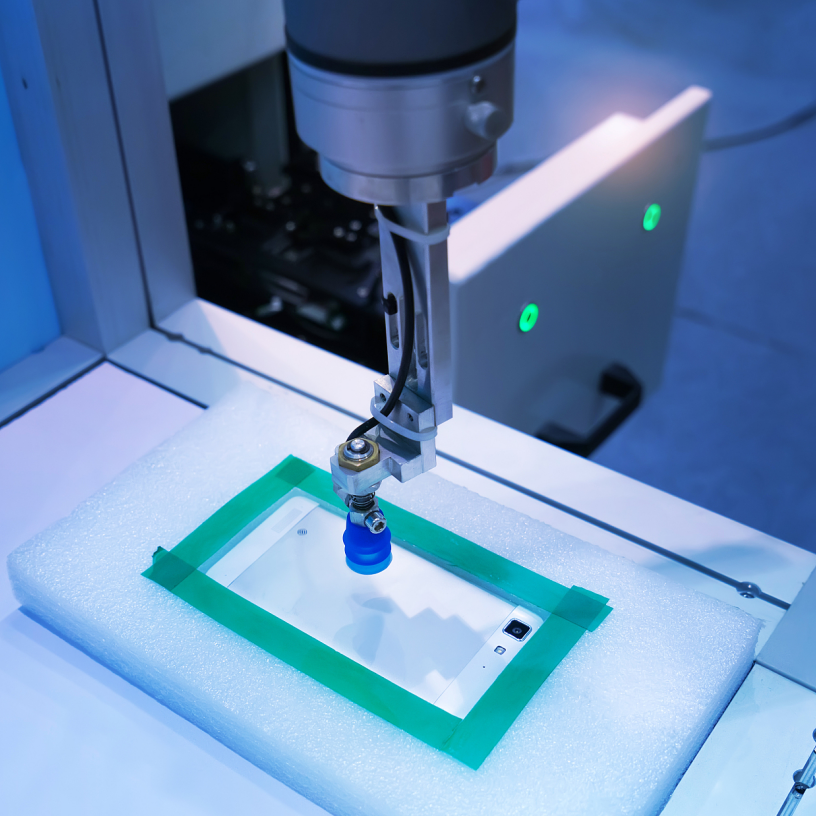

Pneumatic suction cups can achieve stable grasping of tiny components through precise air pressure control, avoiding damage or displacement that may be caused by traditional mechanical clamping. Especially in the production lines of precision electronic products such as smartphones and wearable devices, the application of pneumatic suction cups has significantly improved assembly efficiency and yield rate.

Festo, a well-known German automation equipment manufacturer, demonstrated its latest high-precision pneumatic suction cup system at the forum. By integrating AI algorithms, the system can adjust the suction force in real time to adapt to components of different sizes and materials, further improving the flexibility and precision of assembly.

Industry insiders predict that as electronic components develop towards smaller, lighter, and more complex directions, pneumatic suction cup technology will be more widely used in the next few years. At the same time, its deep integration with robotics technology will also open up new possibilities for intelligent manufacturing.