Nghiên cứu điển hình: Nhà sản xuất PCB bán dẫn đã giảm 89% phế liệu như thế nào nhờ sử dụng các đầu hút chân không tích hợp

Time: 2025-08-22

Hồ sơ Khách hàng : Nhà sản xuất linh kiện bán dẫn tại Mỹ chuyên về PCB tần số cao dùng cho trạm gốc 5G và máy chủ trung tâm dữ liệu. Khách hàng sản xuất 12.000 bảng mạch mỗi ngày - bao gồm cả mạch linh hoạt siêu mỏng (dày 0,15mm) và bảng HDI với lỗ khoan nhiệt 0,2mm – cung cấp cho các nhà sản xuất chip lớn như [Thương hiệu bán dẫn]. Trước khi hợp tác cùng Suzhou Shuowei Automation Technology Co., Ltd. ,họ gặp phải những vấn đề xử lý liên tục đe dọa mục tiêu chất lượng 99,5%.

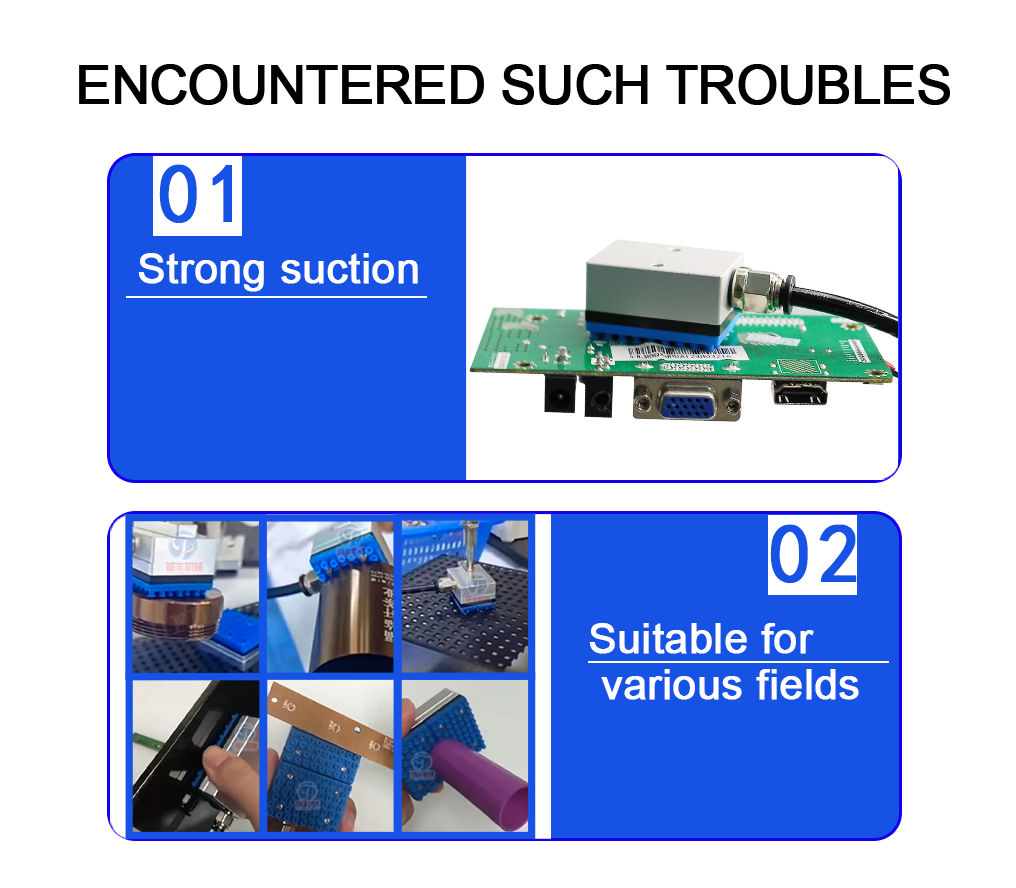

Các thách thức riêng cho ngành bán dẫn: Vì sao các bộ gắp truyền thống thất bại

PCB bán dẫn đòi hỏi quy trình xử lý nghiêm ngặt hơn so với các bo mạch điện tử tiêu dùng: chúng yêu cầu độ chính xác định vị dưới 0,1mm, không có bất kỳ sự nhiễm bẩn nào trên bề mặt, và khả năng tương thích với môi trường phòng sạch (Class 1000). Các bộ gắp chân không truyền thống mà khách hàng đang sử dụng không thể đáp ứng các tiêu chuẩn này, dẫn đến ba vấn đề đau đầu sau:

1. Rò rỉ nghiêm trọng trên các lỗ via HDI

Các mẫu PCB 5G của khách hàng có hơn 20 lỗ via nhiệt 0,2mm mỗi bo mạch để tản nhiệt từ các chip tần số cao. Các bộ gắp thông thường sử dụng buồng chân không đơn đã bị rò rỉ không khí qua các lỗ via này, khiến người vận hành phải tăng áp suất lên đến 12 kPa – đủ mạnh để làm cong các lớp đồng mỏng (dày 18μm) trên PCB và khiến 7,8% bo mạch không vượt qua kiểm tra điện.

2. Trầy xước làm hỏng lớp phủ hàn (và làm mất lòng tin khách hàng)

Các PCB bán dẫn sử dụng lớp phủ hàn siêu nhạy cảm (dày 30μm) để bảo vệ khỏi nhiễu điện. Các núm cao su hút chân không của khách hàng đã để lại các vết xước vi mô trên 6,2% các bo mạch — ngay cả khi thiết lập áp suất thấp. Vì khách hàng bán dẫn từ chối mọi hư hại về mặt thẩm mỹ (lo ngại lớp phủ hàn sẽ suy giảm theo thời gian), những vết xước này đã gây ra tổn thất 42.000 USD mỗi tháng do phế liệu.

3. Quá trình chuyển đổi chậm cho các kích thước PCB tùy chỉnh

Khách hàng sản xuất 15 kích thước PCB tùy chỉnh hàng tháng (từ các bo mạch máy chủ 60x80mm đến các module 5G 40x50mm). Các bộ gá truyền thống yêu cầu 2,5 phút để điều chỉnh lại vị trí các núm hút thủ công mỗi lần chuyển đổi — dẫn đến 37,5 phút dừng máy mỗi ngày — và vẫn sai lệch mục tiêu định vị 0,3mm, dẫn đến 2,1% bo mạch bị lệch khi khoan laser.

4. Bộ gá cồng kềnh gây cản trở dây chuyền phòng sạch

Hành lang phòng sạch giữa các lò hồi lưu và trạm kiểm tra chỉ rộng 140mm. Các bộ gắp tiêu chuẩn (2,1kg, có ống dẫn bên ngoài) không thể lắp vừa mà không gây va chạm với thiết bị khác – buộc khách hàng phải vận hành từng dây chuyền một, làm giảm 50% công suất.

“Chúng tôi cung cấp chip dùng cho trung tâm dữ liệu – nếu một bo mạch PCB bị lỗi, toàn bộ mạng lưới sẽ bị ảnh hưởng,” ông [Raj Patel], Giám đốc Sản xuất của khách hàng cho biết. “Tỷ lệ phế phẩm của chúng tôi là 16,1% – cao hơn nhiều so với tiêu chuẩn ngành là 0,5% – và chúng tôi đang mất hai khách hàng lớn vì vấn đề chất lượng. Chúng tôi cần một bộ gắp được thiết kế riêng cho máy bán dẫn Bo mạch PCB, chứ không phải các bộ phận thông thường."

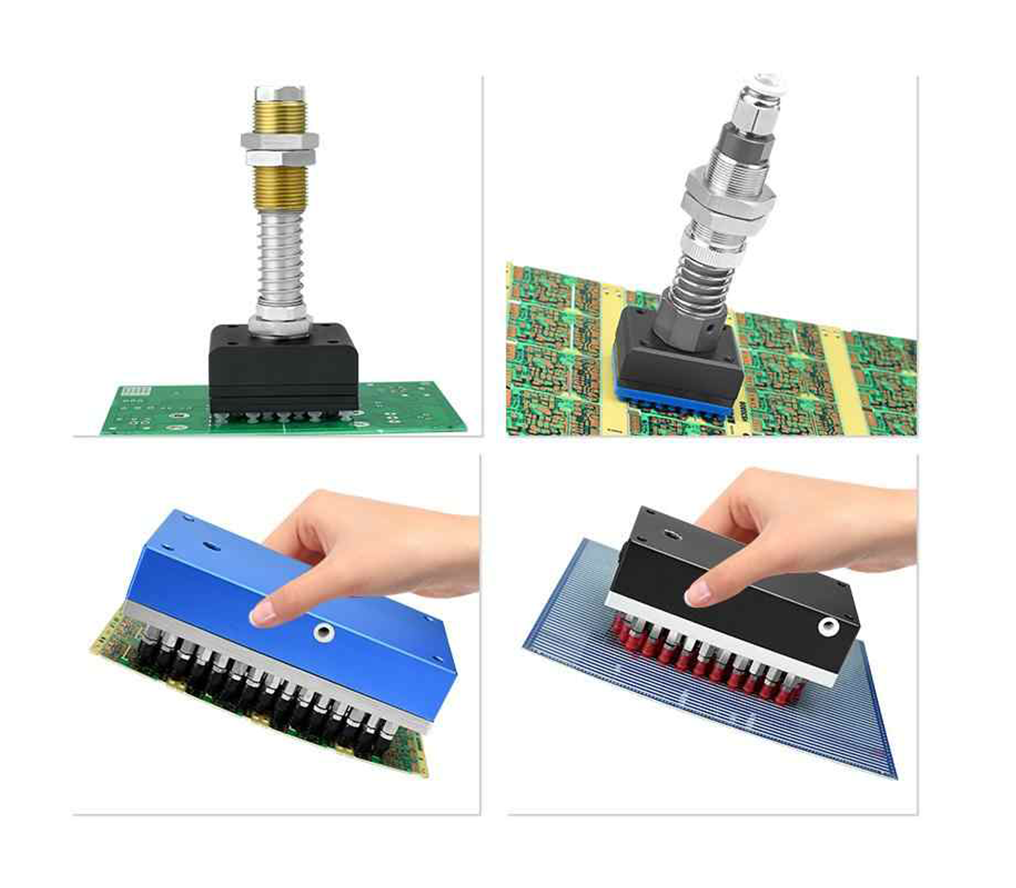

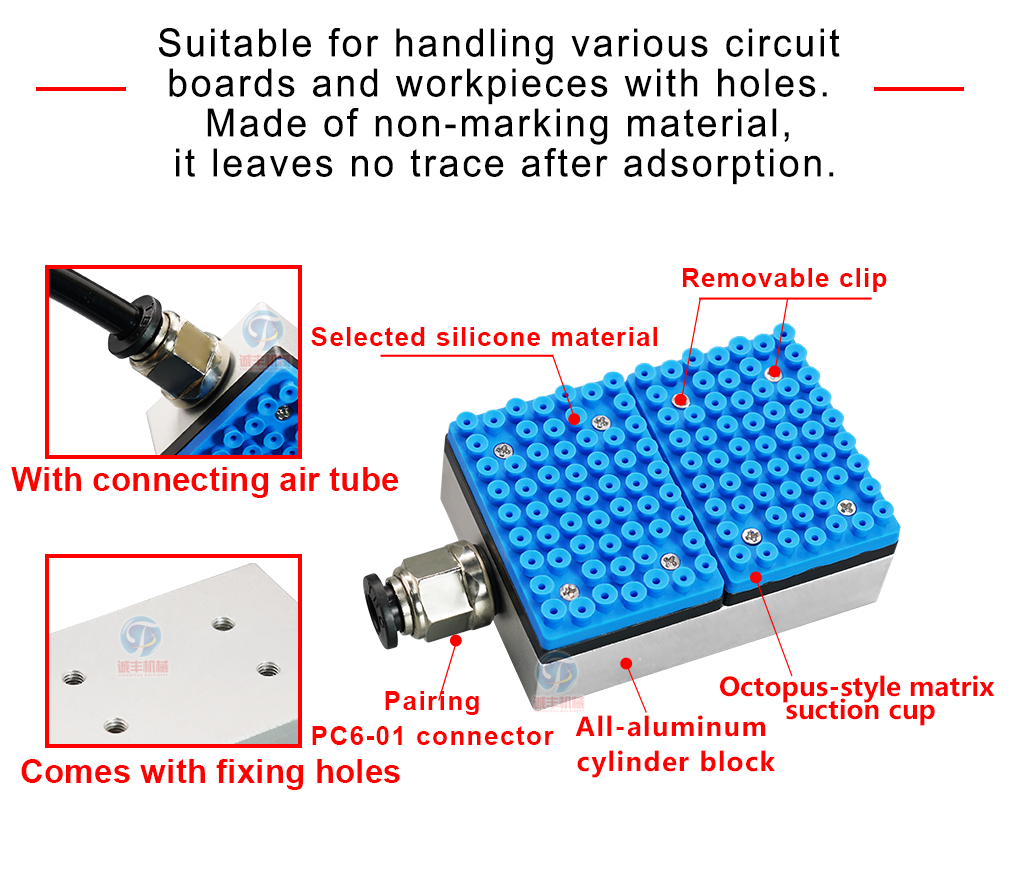

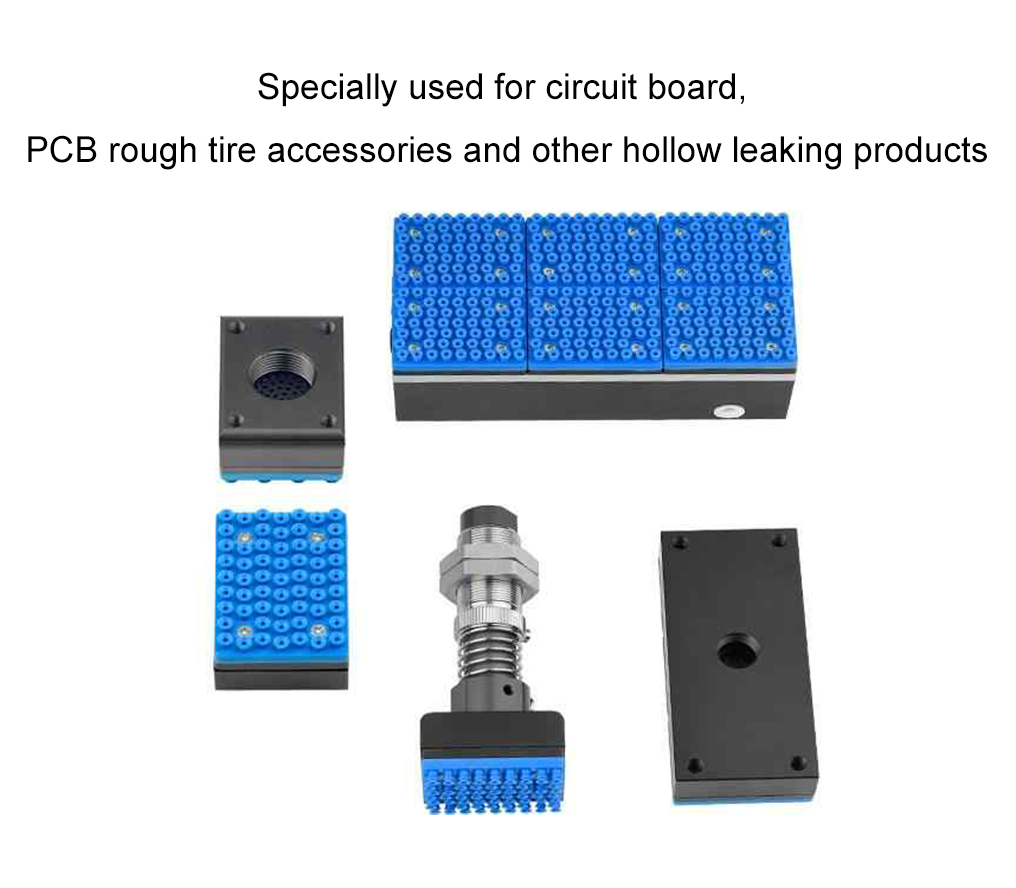

Giải pháp: Suzhou Shuowei Automation Technology Co., Ltd. các Đầu Hút Chân Không Tích Hợp (Điều Chỉnh Cho Bán Dẫn)

Sau khi rà soát quy trình làm việc trong phòng sạch của khách hàng và thử nghiệm các bo mạch PCB dùng cho 5G/máy chủ của họ, chúng tôi đã tùy chỉnh đầu hút tích hợp để đáp ứng các yêu cầu đặc thù của ngành bán dẫn. Dưới đây là cách từng tính năng giải quyết các điểm đau riêng biệt:

1. Van Kiểm Áp Suất Thấp: Không Rò Rỉ Trên Lỗ Via 0,2mm

Chúng tôi trang bị cho bộ gắp van kiểm áp suất thấp chuyên dụng cho ngành bán dẫn (hiệu chuẩn cho lỗ 0,1-0,3mm) có khả năng bịt kín các khoang hút riêng lẻ ngay lập tức khi không khí tiếp xúc với một lỗ via. Khác với van tiêu chuẩn (phải mất 0,1 giây để phản ứng), sản phẩm của chúng tôi kích hoạt trong 0,03 giây — đủ nhanh để ngăn chặn các đột biến áp suất. Chúng tôi cũng giảm áp suất chân không tối đa xuống còn 6 kPa (an toàn cho các lớp đồng 18μm) trong khi vẫn duy trì lực giữ.

Kết quả? Không còn hiện tượng bo mạch bị cong vênh. Tỷ lệ phế phẩm liên quan đến lỗ via của khách hàng giảm từ 7,8% xuống còn 0,5% trong tuần đầu tiên.

2. Cốc silicon đạt chứng nhận phòng sạch: Không trầy xước, ngăn ngừa nhiễm bẩn

Chúng tôi thay thế silicon tiêu chuẩn bằng Silicon đạt tiêu chuẩn thực phẩm FDA Class VI (độ cứng Shore A 28) — cùng loại vật liệu được sử dụng trong thiết bị y tế — cho các cốc hút chân không. Các cốc này:

- Không để lại cặn bã (yếu tố quan trọng để đáp ứng tiêu chuẩn phòng sạch Class 1000) và chống chịu được cồn isopropyl (được sử dụng để làm sạch hàng ngày).

- Phù hợp với các lớp phủ hàn 30μm mà không gây áp lực — loại bỏ hoàn toàn các vết xước vi mô.

- Chịu được nhiệt độ 180°C trong lò hàn reflow (quy trình xử lý sau hàn của khách hàng yêu cầu các bo mạch phải đi qua buồng nhiệt 175°C).

Trong vòng hai tuần, tỷ lệ phế phẩm về ngoại quan do trầy xước giảm xuống 0% - tiết kiệm 42.000 USD/tháng.

3. Khay dạng ma trận với căn chỉnh bằng tia laser: Độ chính xác 0,05mm cho kích thước tùy chỉnh

Để giải quyết vấn đề chậm trễ và lệch vị trí khi chuyển đổi, chúng tôi đã sử dụng một bộ khay nam châm dạng ma trận 5x7 (đường kính 10mm, nhỏ hơn tiêu chuẩn 12mm thông thường để phù hợp với bo mạch PCB kích thước nhỏ 40x50mm) kết hợp với công cụ căn chỉnh bằng tia laser. Bây giờ, công nhân vận hành có thể:

- Chọn kích thước bo mạch từ màn hình cảm ứng của tay gắp (đã được cài đặt sẵn 15 kích thước tùy chỉnh).

- Tia laser chiếu một đường dẫn lên tay gắp, và các khay tự động khóa vị trí trong 8 giây (so với 2,5 phút khi thực hiện thủ công).

- Độ chính xác định vị được cải thiện lên 0,05mm - vượt trội so với yêu cầu 0,1mm của khách hàng cho việc căn chỉnh khoan laser.

Thời gian dừng máy để chuyển đổi giảm từ 37,5 phút xuống còn 2 phút mỗi ngày, và tỷ lệ phế phẩm do lệch vị trí giảm từ 2,1% xuống còn 0,1%.

4. Xi Lanh Hợp Kim Nhôm: Nhỏ Gọn, Sẵn Sàng Cho Phòng Sạch

Chúng tôi thiết kế lõi của bộ gắp bằng hợp kim nhôm 6061-T6 được anod hóa (chống chịu được hóa chất trong phòng sạch), giúp giảm khối lượng xuống còn 0,9kg (nhẹ hơn 48% so với bộ gắp cũ của họ) và thu gọn chiều rộng tổng thể xuống còn 130mm — đủ hẹp để vừa với lối đi phòng sạch 140mm của họ. Chúng tôi cũng tích hợp hệ thống phân phối chân không vào bên trong xi lanh (không cần ống dẫn bên ngoài) để tránh bụi bám và đơn giản hóa việc vệ sinh.

Khách hàng hiện có thể vận hành hai dây chuyền đồng thời, tăng 50% năng suất mà không cần mở rộng phòng sạch.

5. Tích Hợp Tất Cả Trong Một: Kích Hoạt Nhanh Cho Dây Chuyền Tốc Độ Cao

Dây chuyền sản xuất bán dẫn vận hành ở tốc độ 40 bảng/phút — nhanh hơn các dây chuyền điện tử tiêu dùng — vì vậy chúng tôi đã tối ưu hóa thời gian kích hoạt chân không của bộ gắp xuống còn 0,12 giây (nhanh hơn 20% so với mẫu tiêu chuẩn của chúng tôi). Thiết kế xi lanh nhôm giúp tản nhiệt tốt cũng ngăn chặn hiện tượng giảm áp suất trong ca làm việc kéo dài 12 giờ (điều này rất quan trọng đối với hoạt động sản xuất 24/7 của khách hàng).

Tốc độ dây chuyền của họ vẫn duy trì ở mức 40 bảng/phút, nhưng hiện tại không còn thời gian dừng máy do lỗi kẹp nữa.

Kết quả: Giảm 89% phế phẩm, Tăng 50% công suất

Sau 30 ngày triển khai đầy đủ, quy trình sản xuất PCB bán dẫn của khách hàng đã được chuyển đổi hoàn toàn:

- Tỷ lệ phế phẩm tổng : Từ 16,1% xuống 1,8% (giảm 89%) — đạt tiêu chuẩn ngành 0,5% trong vòng 60 ngày.

-

Chi phí phế phẩm hàng tháng : Từ

8.500 (tiết kiệm 89%) — 834.000 USD mỗi năm.

- Dung tích : Tăng 50% (từ 12.000 lên 18.000 bảng PCB mỗi ngày) bằng cách vận hành hai dây chuyền phòng sạch.

- Duy trì Khách Hàng : Hai khách hàng từng đe dọa chấm dứt hợp tác đã gia hạn hợp đồng, và khách hàng còn giành được đơn hàng mới trị giá 2.000.000 USD/năm từ [Thương hiệu Bán dẫn].

“Trước đây, chúng tôi phải kiểm tra từng bảng thứ 10 để phát hiện trầy xước hoặc cong vênh,” ông [Raj Patel] cho biết. “Giờ đây, chúng tôi chỉ cần kiểm tra một trên 100 bảng — vì kẹp gắp không bao giờ hỏng. Chúng tôi không chỉ đáp ứng các tiêu chuẩn — mà còn đang thiết lập chúng.”

Về lâu dài, khách hàng dự báo một lợi nhuận 6 tháng trên các bộ gắp—nhờ tiết kiệm vật liệu phế thải và tăng công suất.

Tại Sao Giải Pháp Này Hiệu Quả Với PCB Linh Kiện Bán Dẫn (So Với Các Giải Pháp Chung)

Sự khác biệt không chỉ nằm ở bộ gắp—mà còn ở việc điều chỉnh dành riêng cho ngành bán dẫn . Chúng tôi không chỉ đơn thuần "bán một công cụ"—chúng tôi:

- Thử nghiệm bộ gắp cùng với vật liệu PCB chính xác của khách hàng (đồng 18μm, mặt nạ hàn 30μm) trong phòng sạch của họ.

- Hiệu chỉnh các tính năng (tốc độ van, giới hạn áp suất, kích thước cốc) để đáp ứng các tiêu chuẩn chất lượng của ngành bán dẫn.

- Cung cấp dịch vụ bảo trì tương thích với môi trường phòng sạch (ví dụ: chất bôi trơn an toàn với cồn) để tránh gây dừng máy.

“Các loại kẹp vạn năng được thiết kế cho 'các bộ phận'—của bạn được thiết kế dành riêng cho chúng tôi các bộ phận của bạn,” ông [Raj Patel] nói thêm. “Đó chính là sự khác biệt giữa một nhà cung cấp và một đối tác.”

Sẵn sàng giải quyết các vấn đề khó khăn trong việc xử lý PCB bán dẫn của bạn?

Nếu bạn đang gặp khó khăn với tình trạng rò rỉ, trầy xước hoặc thời gian dừng máy đối với các bo mạch PCB dùng cho 5G, máy chủ hoặc chipset, các đầu hút chân không tích hợp của chúng tôi có thể được điều chỉnh phù hợp với quy trình bán dẫn cụ thể của bạn.

- Yêu cầu kiểm tra miễn phí trong phòng sạch : Gửi cho chúng tôi một mẫu PCB phức tạp nhất của bạn, và chúng tôi sẽ tiến hành kiểm tra trong phòng thí nghiệm đạt tiêu chuẩn Class 1000—chia sẻ kết quả video và báo cáo hiệu suất tùy chỉnh.

- Xem bản trình diễn bán dẫn : Xem cách bộ kẹp xử lý các mạch linh hoạt dày 0.15mm và các lỗ khoan (vias) dày 0.2mm trong môi trường phòng sạch trực tiếp.

- Nhận báo giá cá nhân hóa : Cho chúng tôi biết kích thước PCB của bạn, tiêu chuẩn phòng sạch và mục tiêu chất lượng—chúng tôi sẽ thiết kế một giải pháp đáp ứng đúng nhu cầu của bạn.

“Chúng tôi nghĩ rằng sẽ phải đầu tư 500.000 USD vào một phòng sạch mới để giải quyết các vấn đề của mình. Thay vào đó, chúng tôi đã đầu tư vào các bộ kẹp phù hợp với không gian hiện có — và giải quyết được các vấn đề về chất lượng. Suzhou Shuowei Automation Technology Co., Ltd. không chỉ giúp chúng tôi tiết kiệm tiền — họ đã cứu doanh nghiệp của chúng tôi.” — [Raj Patel], Giám đốc Sản xuất