Reinventing Precision: How Pneumatic Clamping Technology Is Changing Manufacturing

The Silent Revolution in Industrial Workholding

Introduction

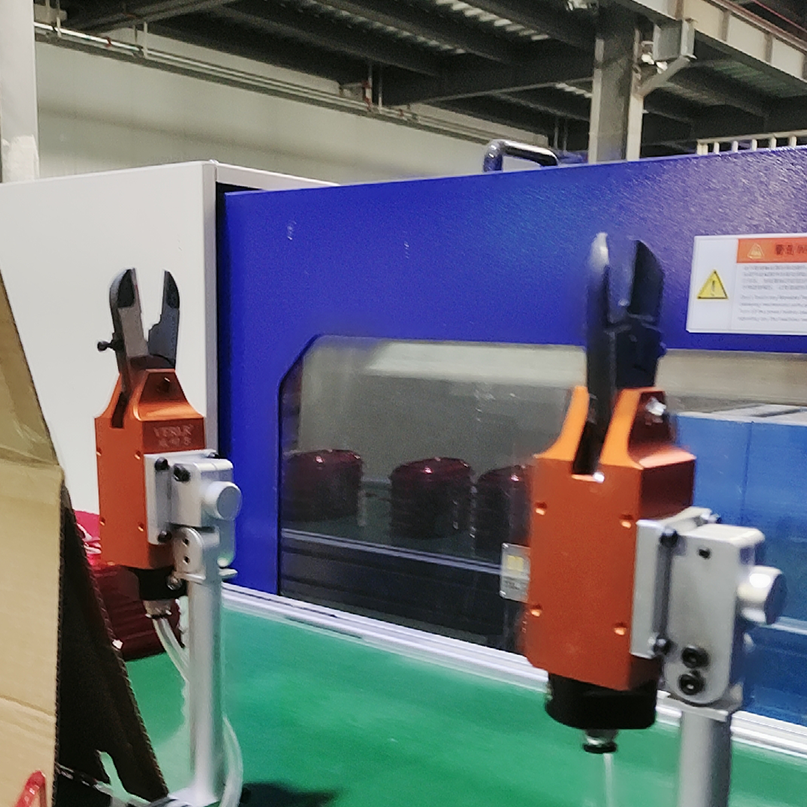

In the world of high-precision manufacturing, pneumatic clamping systems represent a breakthrough beyond traditional workholding technologies. Since their widespread adoption in the 1980s, these compressed air solutions have redefined the standard of precision in the aerospace, automotive, and medical sectors, achieving micron-level consistency while eliminating human error.

Engineering Principles: The Science of Pneumatic Stability

1. Force Generation

Regulated air (4-6 bar) drives cylinders, generating 500-20,000N of clamping pressure

2. Dynamic Response

Millisecond regulation compensates for the thermal expansion of materials during processing

3 . Fail-safe Mechanism

Spring-return piston maintains grip when power is lost

Technical Insight: Modern systems can achieve repeatability of ±0.003 mm, equivalent to one-thirtieth the width of a human hair.

Specific Industry Application Cases

① Aerospace Turbine Production

- Zero-vibration titanium milling at 40,000 RPM

- 22% reduction in scrapped parts (Boeing 2024 data)

② Electric Vehicle Battery Assembly

- Spark-free lithium cell immobilization

- 30-second module changeovers vs. 8 minutes manually

③ Micro Medical Component Manufacturing

- Non-marring polymer grips for implant manufacturing

- ISO 13485-compliant cleanroom integration