In the realm of industrial cutting tools, pneumatic shears stand out as a reliable and efficient solution, driven by compressed air to deliver high-performance cutting across diverse applications. Let’s explore how these tools work, their key advantages, and where they shine in professional settings.

What Are Pneumatic Cutting Tools?

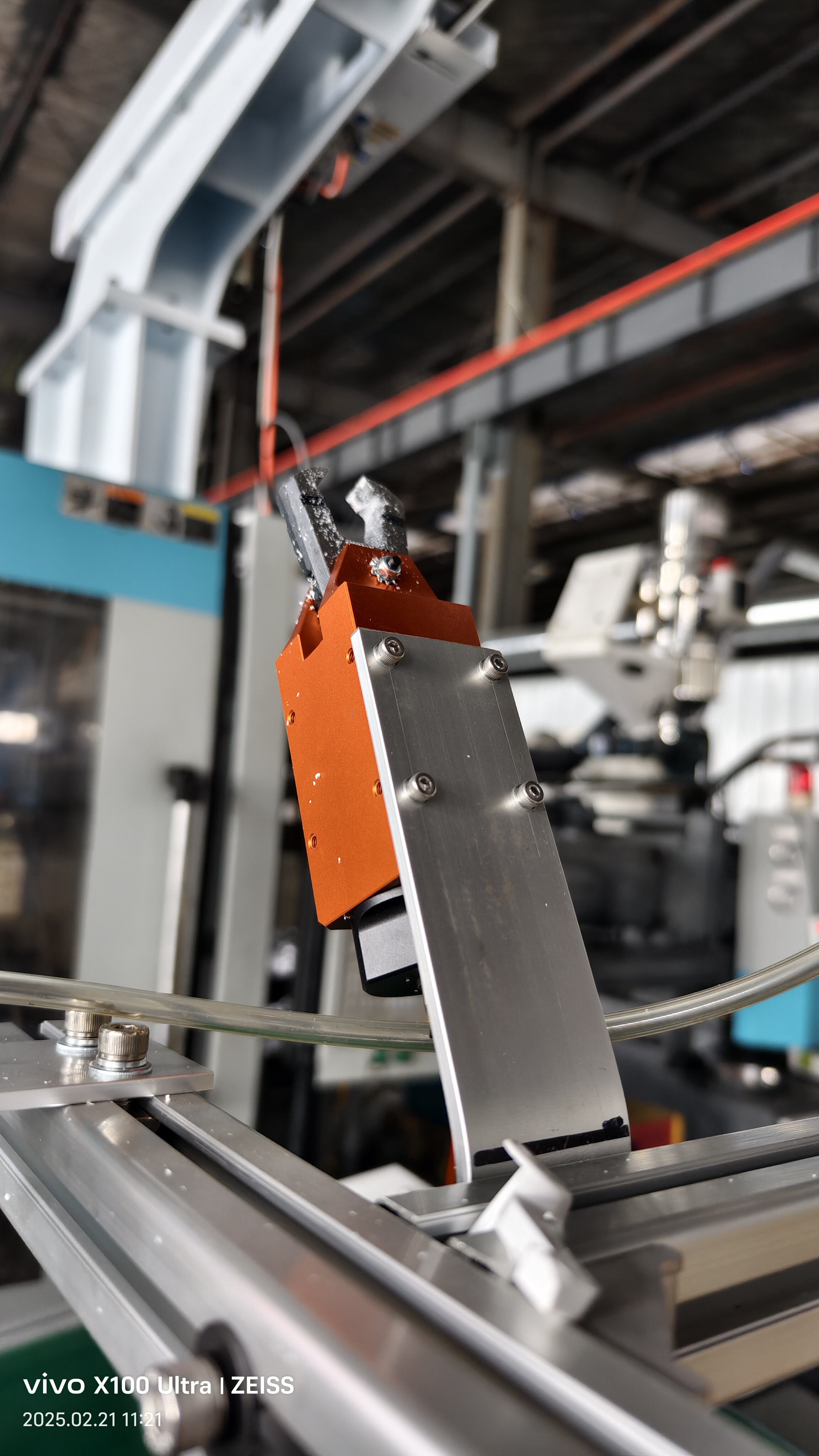

Pneumatic cutting tools are power-driven shears that use compressed air as their energy source, replacing traditional electric motors with a pneumatic motor to drive sharp blades. This design enables them to perform rapid, precise cuts on tough materials like metal sheets, plastics, and rubber, making them indispensable in industries such as manufacturing, automotive repair, and metalworking.

Unlike electric tools, they require a connection to an air compressor rather than a power outlet. This reliance on compressed air eliminates the risk of electric sparks, making them ideal for explosive or flammable environments—from oil refineries to chemical plants—where safety is paramount.

How Do Pneumatic Shears Work?

The magic of pneumatic cutting tools lies in their simple yet effective mechanics, which convert air pressure into a powerful cutting motion:

- Air Path Transmission

Compressed air travels through a hose from the air compressor into the tool’s pneumatic motor. This air pressure drives a piston inside the motor, creating rapid back-and-forth movement.

- Mechanical Conversion

The piston’s linear motion is transferred to a crank mechanism, which converts it into the up-and-down shearing action of the blades.

- Cutting Process

The active upper blade and fixed lower blade form a precise shear angle. As they move in (staggered) motion—often at thousands of cycles per minute—they cleanly slice through materials without crushing or deforming them.

Key Advantages of Pneumatic Cutting Tools

- Safety First: No electrical components mean zero risk of sparks, making them safe for volatile environments (e.g., gas stations, paint booths).

- Unmatched Efficiency: Blades operate at ultra-high frequencies (up to several thousand cycles/minute), cutting through 0.5–3mm metal sheets, thick plastics, or rubber with ease.

- Lightweight Design: Crafted from aluminum alloy, these tools weigh 1/3 that of electric shears, reducing operator fatigue during extended use.

- Low Maintenance: With no complex wiring, upkeep is simple—just regular lubrication and blade replacements to keep performance consistent.

Typical Applications

Pneumatic shears excel in scenarios demanding speed, precision, and safety:

|

Industry |

Common Uses |

Key Benefits |

|

Automotive Manufacturing |

Cutting body panels, trimming interior materials |

Precise curved cuts, no burrs on metal edges |

|

Aerospace |

Cutting composite laminates |

Anti-static design prevents material damage |

|

Metalworking |

Cutting stainless steel/aluminum sheets |

Continuous high-speed operation, no overheating |

|

Packaging |

Slitting thick plastic films or corrugated cardboard |

Quick blade changes for versatile materials |

Pneumatic vs. Traditional Cutting Tools

How do pneumatic shears compare to electric or manual alternatives?

|

Feature |

Pneumatic Shears |

Electric Shears |

Manual Shears |

|

Power Efficiency |

High (air pressure-driven) |

Medium (motor-driven) |

Low (manual force) |

|

Safety in Hazardous Areas |

Excellent (no sparks) |

Risky (potential electric shock) |

Safe but slow |

|

Cutting Capacity |

0.5–3mm metal sheets |

0.5–2mm metal sheets |

≤1mm thin materials |

|

Weight |

Light (aluminum alloy) |

Heavier (motor + wiring) |

Variable (depends on design) |

Choosing the Right Pneumatic Shear

- Blade Type: Opt for tungsten carbide blades for metal cutting; coated blades work best for plastics/rubber.

- Air Pressure: Ensure your air compressor delivers 0.6–0.8 MPa (standard operating pressure).

- Ergonomics: Look for models with shock-absorbing handles and 90° rotating heads for tight spaces.

Pro Tip: Always check air quality—moisture or debris in the air supply can damage the pneumatic motor. Wear safety goggles to protect against flying debris during operation!

Pneumatic cutting tools blend power, portability, and safety, making them a smart investment for industries where efficiency and hazard prevention are critical. Whether you’re trimming automotive parts or slicing heavy-gauge metal, these air-driven workhorses deliver consistent results, cut after cut.