If you work in electronics, medical device, or smart wearable manufacturing, you know the struggle: Your team spends hours troubleshooting tiny parts—3mm connectors, 0.8mm-thin plastic frames, irregular fasteners—that won’t stay clamped. Standard tools either crush delicate components, slip off micro-surfaces, or force you to waste time adjusting jaws for every batch.

The solution isn’t “stronger” or “smaller” generic clamps—it’s specialized mini fixtures designed for micro-scale challenges. In this blog, we’ll break down the three most common micro-part clamping headaches and how Vacuum Mini Fixtures, Pneumatic Wide Small Clamps, and Silicone-Padded Pneumatic Grippers solve them for good.

Problem 1: Your Micro-Connectors Keep Slipping (Or Breaking)

Smartwatch batteries, PCB components, and micro-sensors (often 3–5mm) are the backbone of modern electronics—but they’re a nightmare to handle. Generic vacuum tools either use too much suction (crushing pins) or too little (dropping parts mid-transfer), leading to:

- Line stops (we’ve seen clients lose 45+ minutes daily to slipped connectors).

-

Damaged components (bent pins mean scrapping

20 parts.

- Missed production targets (even 10 slipped parts/hour adds up).

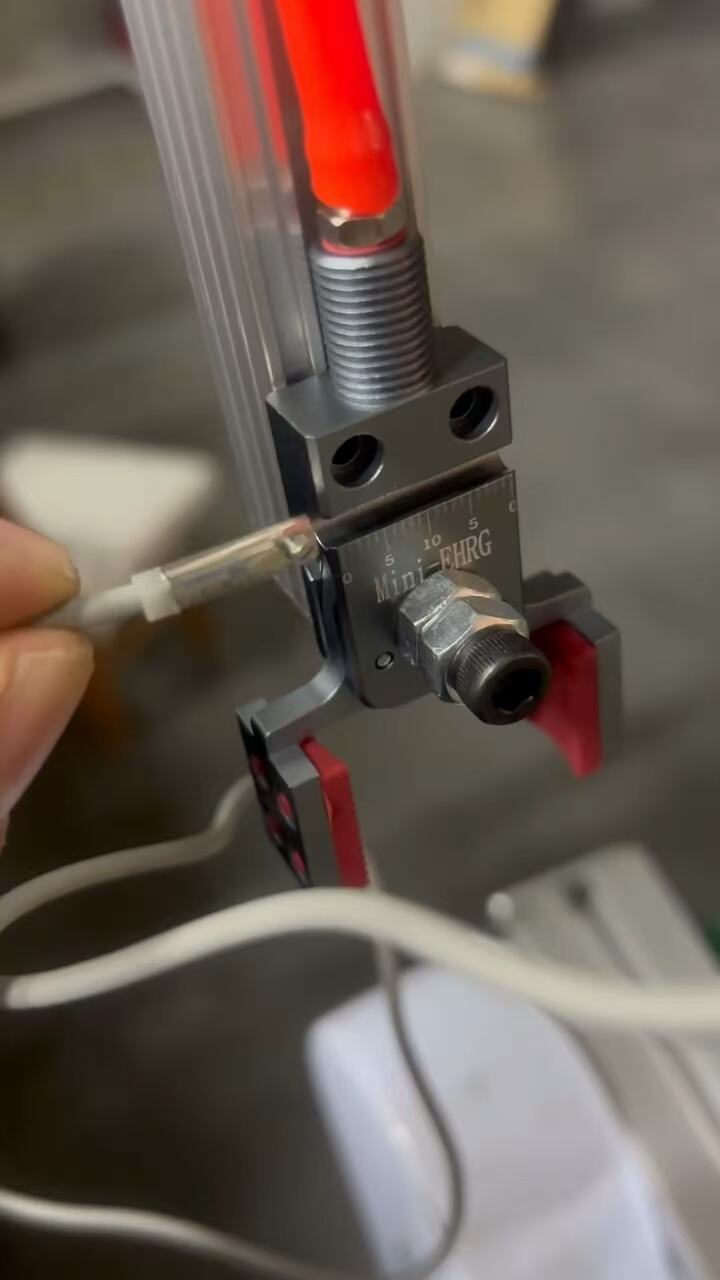

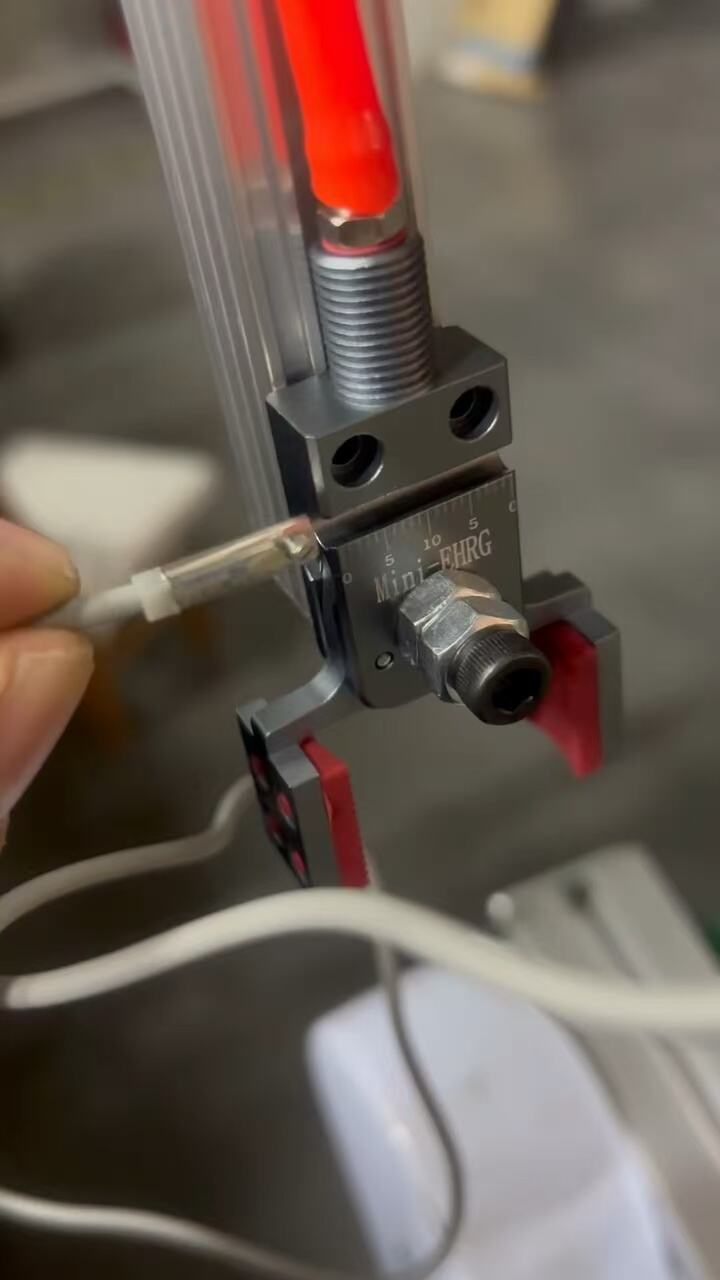

The Fix: Vacuum Mini Fixtures

Vacuum Mini Fixtures are built for parts smaller than a pencil eraser. Here’s how they work:

- Adjustable low-pressure suction: 5–8 kPa (weaker than standard vacuum tools) creates a secure hold without damaging delicate pins. For a 3mm PCB connector, we paired the fixture with a 2mm-diameter suction cup—perfectly matching the connector’s top surface to avoid blocking contacts.

- Ultra-compact design: At 15mm × 10mm × 8mm, they fit on small robotic arms (like Yamaha YSM20 pick-and-place machines) without reconfiguring your line.

- No more slips: A smart wearable manufacturer we worked with went from 8+ daily line stops to zero after switching to these fixtures—saving 45 minutes of downtime each day.

Problem 2: Thin or Coated Parts Get Scratched (Wasting $$$)

Thin plastic display frames (0.5–1mm thick) and coated sensor housings (used in medical devices or fitness trackers) are easily damaged by metal clamps. One client told us they were scrapping 12% of these parts monthly—60,000 pieces—costing $48,000 in wasted materials.

Why? Standard clamps use hard metal jaws that don’t conform to fragile surfaces. Even “gentle” settings leave scratches or indentations, forcing you to sort through dozens of parts to find one usable piece.

The Fix: Silicone-Padded Pneumatic Grippers

These grippers replace metal jaws with soft, adaptable silicone pads—here’s why they’re a game-changer:

- Scratch-free clamping: 3mm-thick food-grade silicone conforms to thin frames and coated surfaces, eliminating marks. The client above cut their damage rate from 12% to 0.9% (just 4,500 scrapped parts/month).

- Fast actuation: Dual-action design opens/closes in 0.2 seconds, keeping up with high-speed assembly lines (they boosted one client’s line speed by 28%).

- Temperature resistance: Works from -10°C to 130°C—ideal for post-curing or low-temperature medical device assembly.

Problem 3: Irregular Parts Force Constant Manual Adjustments

Irregularly sized plastic fasteners (5–10mm) or odd-shaped micro-components demand constant clamp jaw tweaks. One manufacturer told us they spent 2 minutes adjusting narrow-jaw clamps per batch—slowing their line by 18% and tying up operators.

Standard mini-clamps have narrow jaws (4mm or less) that only fit one size. Switching between 5mm and 10mm parts means stopping the line, swapping jaws, and recalibrating—wasting time you can’t afford.

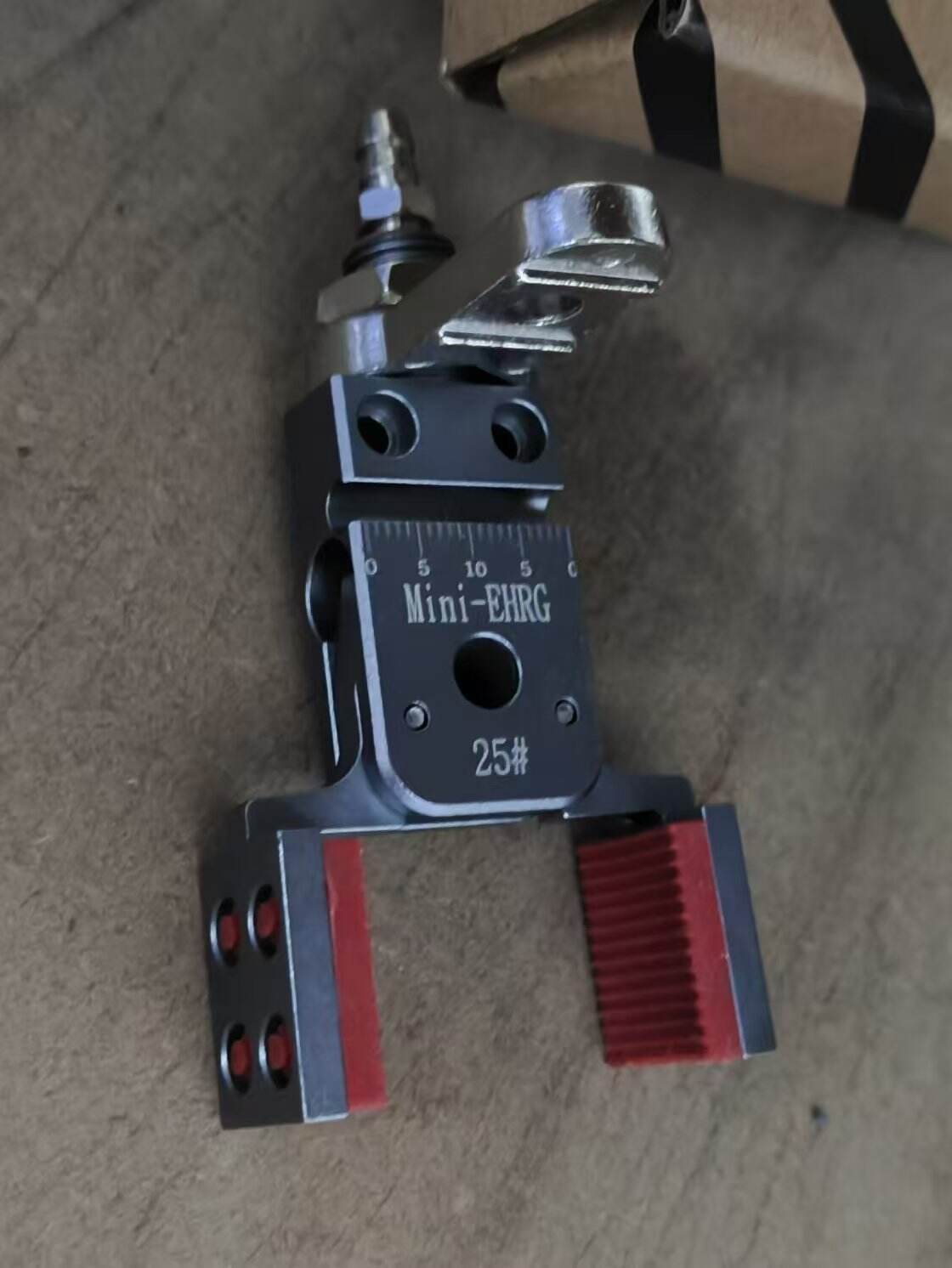

The Fix: Pneumatic Wide Small Clamps

These clamps solve the “one-size-fits-none” problem with wider jaws and quick-change flexibility:

- 12mm-wide jaws: 3x wider than standard mini-clamps, they grip 5–10mm irregular parts without adjustment. No more stopping the line to tweak jaws.

- Quick-change inserts: Swap between plastic inserts (for soft parts) and metal inserts (for rigid ones) in 30 seconds. One client cut batch changeover time by 80%.

- Consistent force: Pneumatic actuation (0.4–0.6 MPa) delivers the same grip every time—no more “too loose” or “too tight” mistakes.

How to Choose the Right Mini Fixture for Your Parts

Not sure which mini fixture fits your workflow? Use this quick checklist:

Ready to Stop Fighting Micro-Part Clamping?

The manufacturers we work with don’t just “upgrade” their clamps—they eliminate a daily headache. One smart wearable client now saves $532,800 annually in waste and downtime, with a 2.7-month ROI.

Here’s how to get started:

- Test your parts for free: Send us a sample of your trickiest micro-part, and we’ll test it with our mini fixtures (no obligation). Request a free test.

- See them in action: Schedule a virtual demo to watch the fixtures handle parts like yours. Book a demo.

- Get a custom quote: Tell us your production volume and part specs, and we’ll tailor a solution. Contact sales.

Got a micro-part clamping problem we didn’t cover? Drop it in the comments—we’ll help you find a fix.