For PCB manufacturers, even the smallest handling mistake can derail production: a scratched copper trace, a porous board that won’t hold vacuum, or a misaligned suction cup that drops a 0.2mm-thin flex PCB. Traditional vacuum grippers—with their separate valves, bulky frames, and one-size-fits-all cups—often make these problems worse, leading to 8-12% scrap rates and costly line downtime.

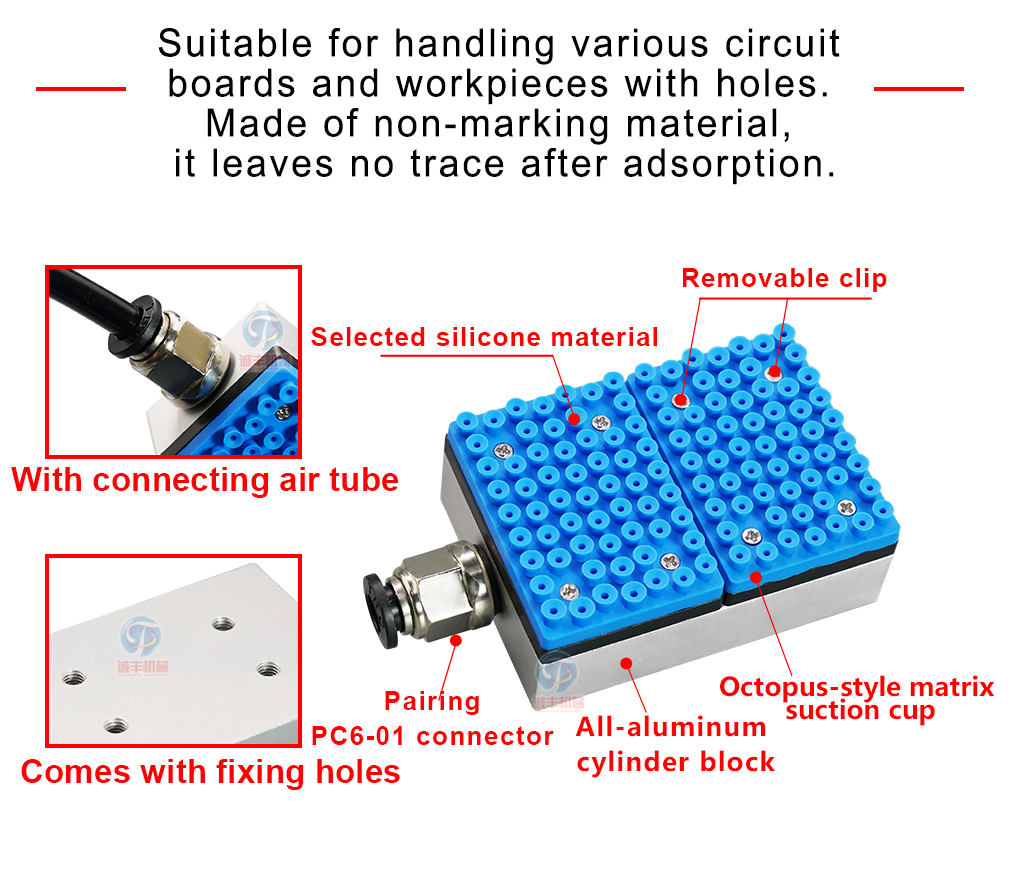

That’s why we designed our PCB Circuit Board Integrated Vacuum Suction Cups—an all-in-one solution built for the unique challenges of handling rigid, flex, and multi-layer PCBs. In this blog, we’ll break down how its key features—porous check valves, matrix-style cups, aluminum alloy cylinders, and scratch-free silicone—solve the top 5 PCB handling pain points.

Pain Point 1: Vacuum Leakage on Porous PCBs (e.g., High-Density Interconnect Boards)

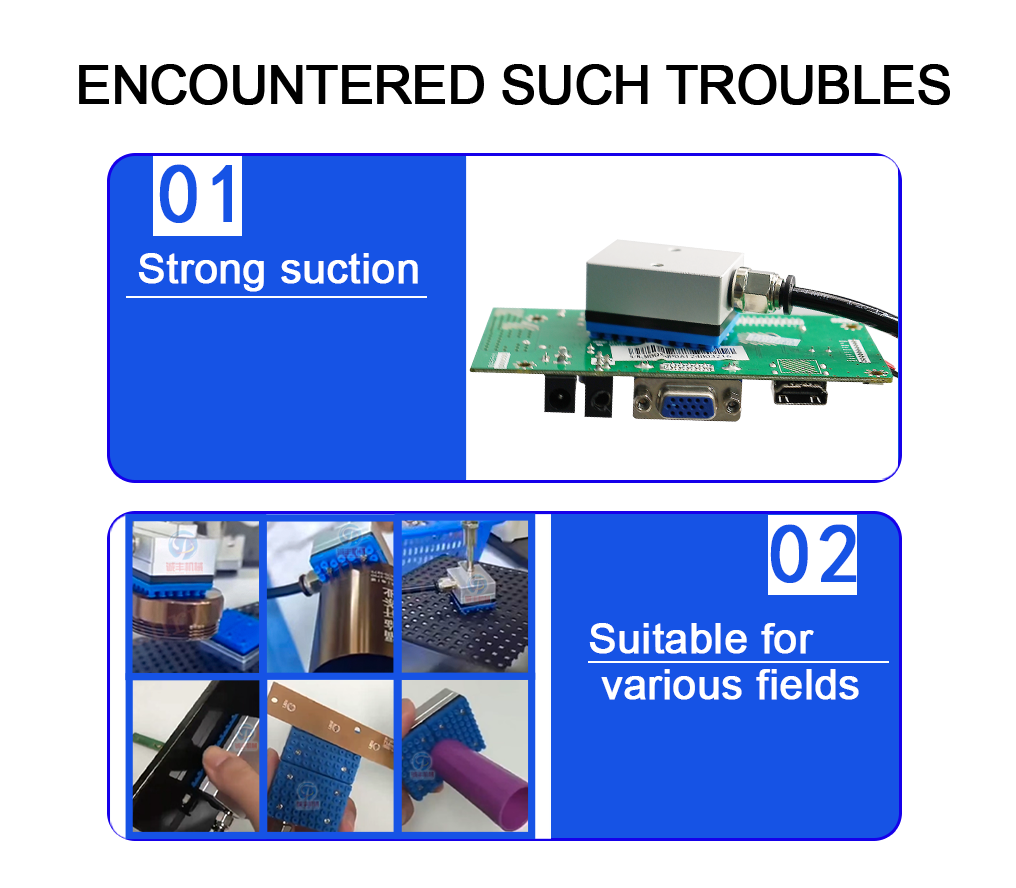

High-density interconnect (HDI) PCBs and boards with thermal vias (0.1-0.3mm holes) are a nightmare for standard suction cups. Air escapes through the pores, forcing you to crank up vacuum pressure—which risks warping the board or damaging delicate components like SMD chips. One of our clients, a medical device PCB maker, was losing 9% of their HDI boards monthly to leakage-related drops.

The Fix: Integrated Porous Check Valves

Our suction cups include built-in PCB-specific porous check valves that seal individual cup chambers the moment air is detected. Each cup in the matrix acts as an independent unit—if one cup covers a via or hole, its check valve closes automatically, preventing air from leaking across the entire gripper. There’s no need for external valves or manual pressure adjustments, either: the system adapts to hole density (from 5-20 holes/cm²) in just 0.05 seconds.

The medical PCB client saw immediate results: they cut leakage-related scrap to 1.2% within 2 weeks, saving $36,000/month in material costs.

Pain Point 2: Scratches on PCB Surfaces (Copper Traces, Solder Masks)

Even soft rubber suction cups can leave marks on solder masks or scratch exposed copper traces, especially when handling thin flex PCBs (0.1-0.3mm thick). A consumer electronics manufacturer we worked with told us they were rejecting 7% of boards purely due to cosmetic damage—most of it from suction cup friction.

The Fix: Food-Grade Silicone Suction Cups

We replaced standard rubber with ultra-soft, food-grade silicone cups (Shore A 30 hardness) to eliminate surface damage. These cups conform to uneven PCB surfaces without applying excessive pressure, ensuring no scratches on solder masks or copper. They also withstand temperatures up to 180°C, making them safe for post-solder handling (such as after reflow ovens), and resist flux and cleaning solvents—unlike rubber cups that harden and degrade after just 3 months of use.

After switching to our silicone cups, the consumer electronics client’s cosmetic scrap rate dropped to 0.8%—an 89% improvement.

Pain Point 3: Misalignment & Dropped PCBs (Variable Board Sizes)

PCB production lines often switch between sizes: a 100x150mm rigid board one batch, a 50x80mm flex board the next. Standard grippers require manual repositioning of cups, which takes 2-3 minutes per changeover and increases the risk of misalignment (and dropped boards). For manufacturers running multiple batches daily, this adds up to hours of lost productivity.

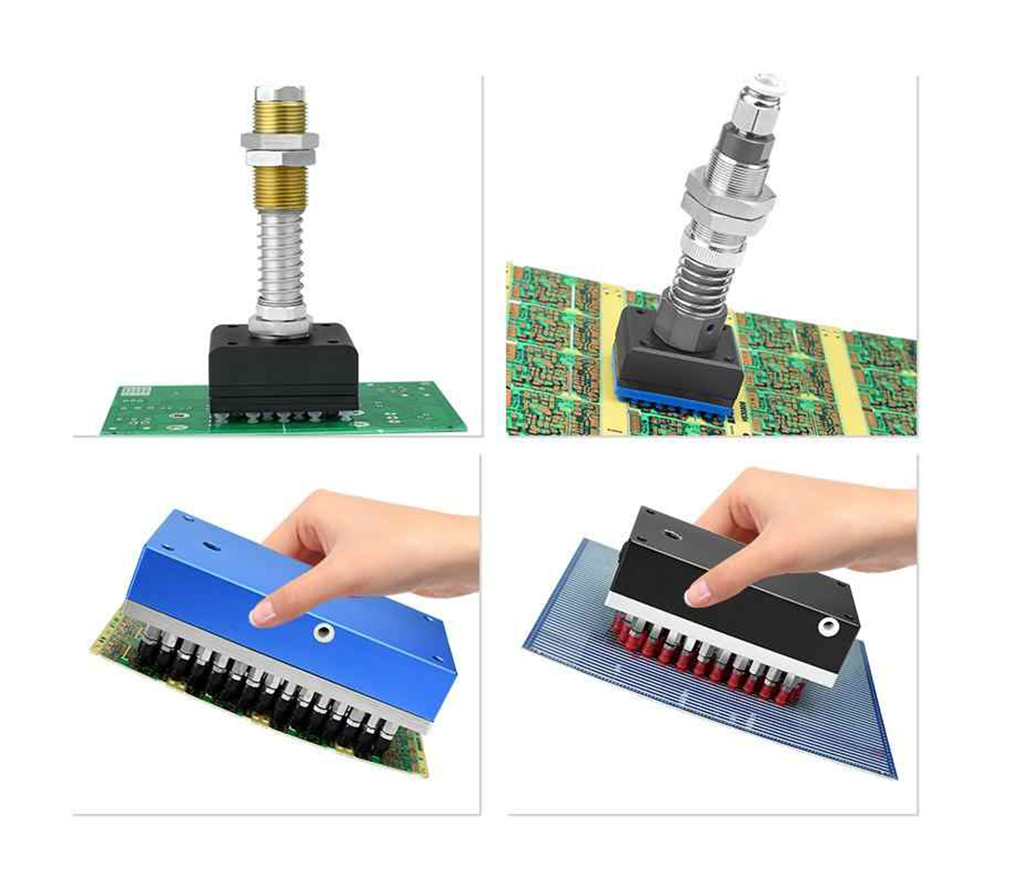

The Fix: Matrix-Style Suction Cup Layout

Our integrated gripper features a 4x6 matrix of adjustable cups (12mm diameter each) that eliminates the need for time-consuming repositioning. The matrix covers board sizes from 50x50mm to 200x300mm, and cups lock in place via a magnetic base in just 10 seconds—compared to 3 minutes for traditional grippers. What’s more, the design maintains 0.1mm positioning accuracy, a critical detail for aligning PCBs with pick-and-place machines and avoiding misplacement.

A contract manufacturer running 8 different PCB sizes daily saw a 95% reduction in changeover time: from 24 minutes/day to just 1.2 minutes, freeing up operators to focus on other tasks.

Pain Point 4: Bulky Grippers Blocking Automated Lines

Traditional PCB grippers combine separate vacuum pumps, valves, and frames, resulting in a bulky design that can’t fit in tight spaces—like between reflow ovens and inspection stations. One automotive PCB maker we spoke to had to redesign their entire line to accommodate a standard gripper, a project that cost $120,000 and delayed production for 6 weeks.

The Fix: Aluminum Alloy Cylinder Body

We built the gripper’s core with a lightweight aluminum alloy cylinder (6061-T6 grade) to solve space and weight issues. This material cuts weight by 40% compared to steel frames—1.2kg vs. 2kg for a 200x300mm gripper—making it compatible with small robotic arms like the Fanuc LR Mate 200iD. The aluminum cylinder also integrates the vacuum manifold directly into its structure, eliminating external hoses or valves that clutter lines. Plus, it resists corrosion from factory humidity and cleaning chemicals, boasting a 5-year lifespan—double that of steel frames.

The automotive client avoided a costly line redesign entirely; now, they fit the gripper in spaces as narrow as 150mm, keeping their automated workflow on track.

Pain Point 5: Slow Vacuum Response (Delaying Production)

When handling high-speed PCB lines (30+ boards/minute), even a 0.5-second delay in vacuum activation can cause bottlenecks. Standard grippers take 0.8-1 second to build pressure—too slow for fast-paced lines that rely on consistent throughput. A smartphone PCB maker told us this delay was limiting their line speed to 32 boards/minute, well below their target of 40.

The Fix: All-in-One Integration

By combining check valves, the vacuum manifold, and cups into a single unit, we eliminated the air flow restrictions that slow down traditional grippers. The result is vacuum activation in just 0.15 seconds—fast enough to keep up with 45-boards/minute lines. The aluminum cylinder also plays a role here: it dissipates heat efficiently, ensuring no pressure drop during continuous use, even after 8 hours of nonstop operation.

After implementing our integrated gripper, the smartphone PCB maker hit their target and beyond—increasing line speed by 25%, from 32 to 40 boards/minute, without adding a minute of downtime.

How to Choose the Right Integrated Vacuum Suction Cup for Your PCBs

Not all PCBs require the same handling solution—here’s how to match our gripper to your specific needs. For HDI or porous PCBs, prioritize models with advanced porous check valves, like our PCB-VAC-46P, which excels at sealing air leaks from vias. If you work with flex or thin PCBs (less than 0.3mm thick), opt for a model with food-grade silicone cups and a low-pressure mode, such as the PCB-VAC-46S, to protect delicate surfaces.

For lines that switch between multiple PCB sizes daily, the PCB-VAC-46M is ideal—it features the matrix cup layout with magnetic locks for fast, tool-free repositioning. And if high-speed production is your priority, the PCB-VAC-46H delivers the fastest vacuum response, ensuring your line keeps up with even the most demanding throughput targets.

See It in Action: Request a Free PCB Test

Don’t just take our word for it—send us a sample of your trickiest PCB (rigid, flex, or porous), and we’ll test it with our integrated vacuum suction cup. We’ll share a video of the test, along with a custom efficiency report showing exactly how much scrap and downtime you could save by switching.

“We used to spend 2 hours/day sorting scratched or dropped PCBs. Now? That time’s gone—thanks to the silicone cups and check valves. It’s the first gripper that actually ‘gets’ PCB handling.” — Mark Chen, Production Manager at a global PCB manufacturer

Table of Contents

- Pain Point 1: Vacuum Leakage on Porous PCBs (e.g., High-Density Interconnect Boards)

- Pain Point 2: Scratches on PCB Surfaces (Copper Traces, Solder Masks)

- Pain Point 3: Misalignment & Dropped PCBs (Variable Board Sizes)

- Pain Point 4: Bulky Grippers Blocking Automated Lines

- Pain Point 5: Slow Vacuum Response (Delaying Production)

- How to Choose the Right Integrated Vacuum Suction Cup for Your PCBs

- See It in Action: Request a Free PCB Test