Vacuum pneumatic suction cup: the core enabler of flexible intelligent manufacturing of automobiles

Global automakers face the dual challenges of mixed-line production of multiple models (single-line ≥ 8 models switching) and lightweight material revolution (aluminum alloy/carbon fiber accounts for more than 35%). Traditional mechanical fixtures are on the verge of being eliminated due to rigid contact damage (annual loss of $2.6 billion) and time-consuming model change (average 45 minutes/time). Vacuum pneumatic suction cups have become the core of flexible production lines through adaptive adsorption + zero-pressure contact - the automotive automation market will reach $134 billion in 2025 (McKinsey forecast), and the penetration rate of vacuum technology will exceed 50%.

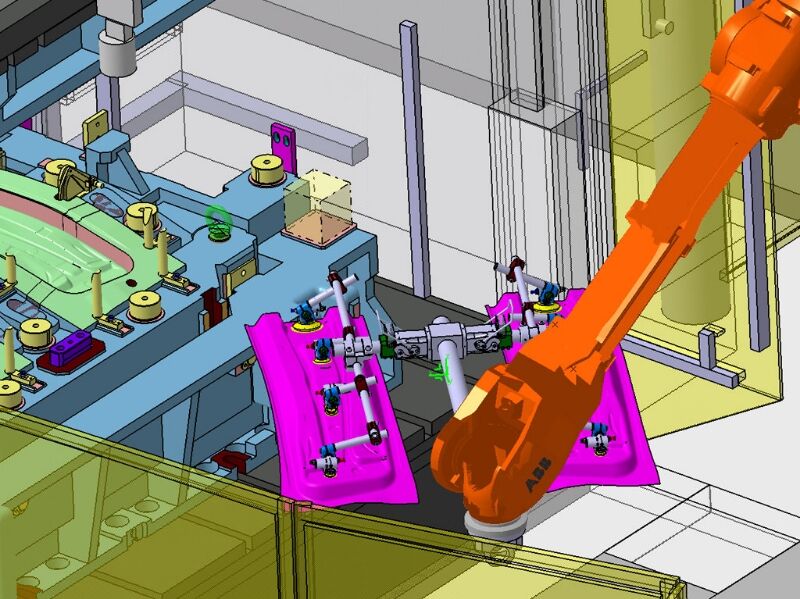

Stamping link: high-precision sheet handling

Industry pain points:

The wrinkle rate of 0.7mm ultra-thin steel plates handled manually is >12%, and the positioning error of laser-welded plates is ±1.5mm.

Solution:

Micropore array suction cup group: automatically adjusts the adsorption force according to the deformation of the plate (200+ independent vacuum areas)

Magnetic-assisted positioning: aluminum alloy plate handling accuracy reaches ±0.2mm (actual measurement at Tesla Berlin factory)

Asian efficiency design:

▶ Low-cost suction cup matrix (compatible with 0.5~2.5m² plates)

▶ Anti-vibration module to cope with power grid fluctuations (±15% voltage)

Material type:

Steel/aluminum&polyurethane suction cup

Carbon fiber silicone & anti-static suction cup

Plastic parts & TPE flexible suction cup

Innovative technology:

▶ Low temperature resistance: -30℃ freezer handling (fluororubber material)

▶ Self-cleaning edge: prevents paint splashing and sticking (saving 2 hours of CIP time per day)

4. Assembly line: flexible component docking

Mixed production core challenge:

When producing an SUV/sedan on the same line, the instrument panel installation error rate is >8%.

Intelligent solution:

3D vision-guided suction cup: Identify different models of front windshields (0.3 seconds/piece)

Force-controlled compliance system: Window installation contact force ≤5N (avoid deformation of sealing strips)

Global cases:

Volkswagen MEB platform: Suction cup system enables seamless switching of 10 models.

Thailand Toyota plant: The Payback period of the investment is only 14 months.