*איך כלים מיוחדים יכולים לכסות את הפער בין רובוטים לבין משימות בעולם האמיתי*

---

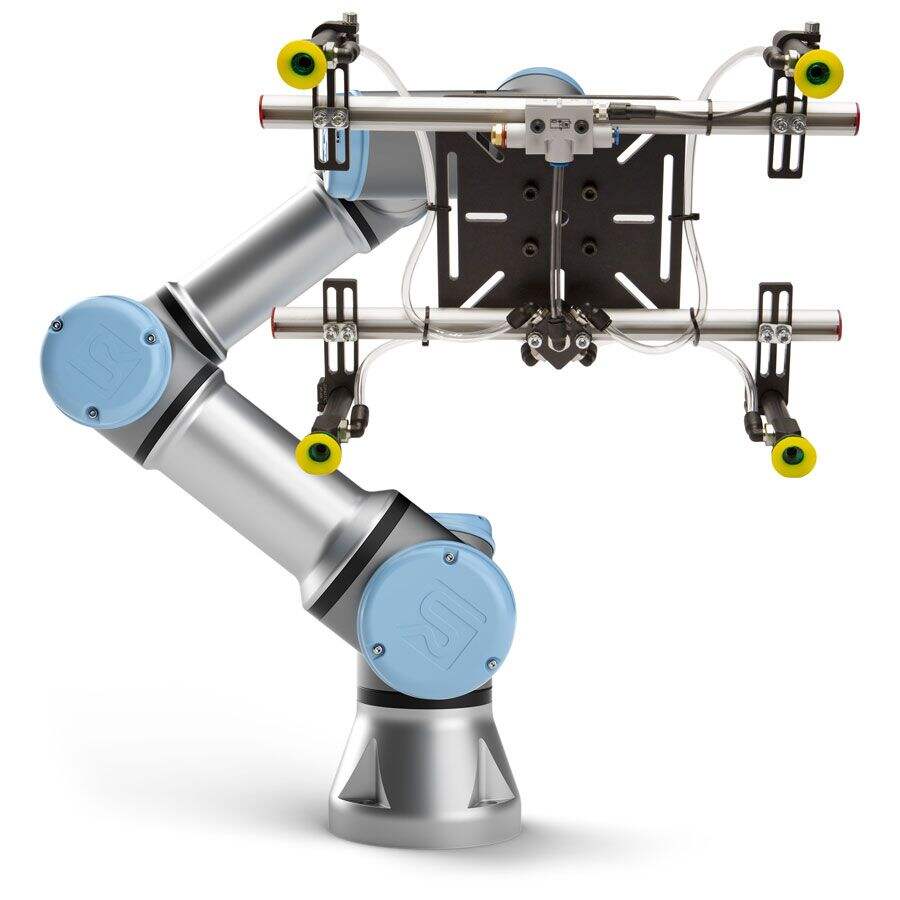

### ? **מהו אנד אפקטור (מנוף)?**

מנופי סיום (EOATs) ממירים את הפוטנציאל של הרובוט לפעולה פיזית. מותקנים בפרק הסיום של זרוע הרובוט, מכשירים אלו **פועלים ישירות עם חלקי העבודה** - תופסים, עוצרים או קוראים עצמים באופן מדויק. ניתן לחשוב עליהם כעל:

- **יד מייחוס למטרה**, המבצעת משימות מגוונות החל מקירורגיה עד ריסוק כבד

- **הרחבות חיישניות**, שגוברות על נתוני כוח/טמפרטורה/ראייה

- **ממשקים מתאימים**, המתרגמים את תנועת הרובוט להשפעה בעולם האמיתי

> *תובנה מרכזית*: רובוט תעשייתי ללא ה-EOAT הנכון דומה לסמארטפון ללא אפליקציות - חומרה חזקה הממתינה לשימוש.

---

### ?️ **ארבע קטגוריות פונקציונליות**

? **1. מערכות אחיזה ותפעול**

*למישוש בטוח של עצמים*

- **אוחז**: עיצוב דו-אצבעי/תלת-אצבעי גמיש (בהתאם לתקן ISO 9409-1) עבור משקלים בין 0.1 גרם עד 2,000 ק"ג

- **פתרונות ספיקה**: כפפות ספיקה לפי עקרון ברנולי ליירוט זכוכית רכה או משטחים נקבוביים

- **מגנטים lifter**: גרסאות אלקטרומגנטיות לשחרור מיידי של דפים מפליז

- **רובוטים רכים**: אוחזנים מסיליקון עם חיישן לחץ מובנה לעצמים בעלי צורות לא סדירות

⚡ **2. כלים לתהליך ייצור**

*המרה ישירה של חומרים*

- **رؤשים להלחמה מדויקת**: רואשים היברידיים להלחמת לייזר עם דיוק בחריץ הלحام עד 0.05 מ"מ

- **דיספנסר מיקרוסקופי**: התקני זריקת פיזوالקטריים לטיפות ציפורן בגודל 3 pL

- **מכונות הסרת קיסים ללא ניצוץ**: ציוד לעיבוד פנים לאזורים מסוכנים

- **מַפְרִיץ פלַזְמָה**: מערכת ציפוי לתעשייה האווירית

? **3. יחידת בדיקה ומדידה**

*איברי החישה של הרובוט*

- **מצלמת היפרספקטרלית**: מאתרת פגמי חומר בקוטר תת-מילימטרי

- **מערך חיישן מגע**: סטדיישן לאישור שלמות האריזה

- **סורק לייזר (LiDAR)**: מאפשר איסוף קופסאות בסביבות ערבוב

- **מנתח טמפרטורה תרמי**: מאייר התפלגות חום במהלך היציקה

?️ **4. מודולי משימה מיוחדים**

*מותאם למשימות בסביבות קיצוניות*

- **מניפולטור קריוגני**: כלי תואם לנוזל חנקן ב-196° צלזיוס

- **כפפות מאושרות לפי ATEX**: עיצוב אטום פיצוץ לתשתיות כימיות

- **כלי ניתוח סטריליים**: מניפולטור לביוופסיות בהתאם לתקן ISO 13485

- **ידית מומנט תת-ימית**: התקנה לשמירה על צינורות באוקיינוס העמוק

---

⚙️ **נקודות עיצוב של ביצועים מרביים**

1. **אופטימיזציה של העומס**

המבנה מפחמן מקטין את המשקל ב-60% תוך שמירה על הקשיחות, מה שמביא להקצרת זמני מחזור. בעת החלפת כלים, יש תמיד לחשב את היסט המרכז הכובד.

2. **גמישות בהחלפה מהירה**

ממשק ISO 16086-1 מאפשר החלפת כלים בתוך פחות מ-0.5 שניות. מערכות מודרניות משתמשות בתגים של RFID להגדרה אוטומטית.

3. **אינטגרציה של משוב חכם**

מדי מאמץ משובצים מאפשרים בקרת כוח הידוק אדפטיבית, וחיישני רטט חוזים כשל מיסבים יותר מ-200 שעות לפני זמן השבתה.

4. **יכולת הסתגלות סביבתית**

מארז בעל דירוג IP69K עומד בלחץ גבוה, וציפוי קרמי שומר על דיוק בטמפרטורות תנור של 800°C.

---

סיפורי טרנספורמציה בתעשייה

**רכב**: רובי ריתוך רובוטיים קיצרו את זמן הייצור של טסלה מודל Y ב-30%

**אלקטרוניקה**: גריסים אנטי-סטטיים מאפשרים לסמסונג להשיג שיעור פגמים בהרכבת שבבים של 99.98%

- **פרמצבטיקה**: מטפל בקבוקונים סטרילי מבטל זיהום במהלך בקבוק חיסון COVID-19

**חקלאות**: תופסנים רכים המצוידים בראייה ממוחשבת יכולים כעת לקצור 20,000 תותים בשעה

---

### ? **החזית הבאה: EOAT קוגניטיבי**

*חומרה פוגשת בינה מלאכותית*

- **כלים הניתנים להגדרה מחדש באופן עצמאי**

אצבעות ייצור מחומרים בעלי זיכרון צורתם מתאימות אוטונומית לאובייקטים לא ידועים

- **אלגוריתמי אחיזה פרוגנוזיים**

למידה מכאנית מנבאת נקודות מגע אופטימליות עבור פריטי אנטיקה שבירים

- **רשתות משוב חaptic**

רוכחים "מרגישים" את התנגדות הרקמה באמצעות רובוטי ניתוח מרחוק

- **פאות מסתימות את פגיעותיהן**

שכבת מיקרו-קפסולות מתקנת סדקים קטנים במהלך הניתוח

---

> **מסקנה חשובה**: EOATs עוקפים את הכלים המכאניקליים – מדובר במערכות **ממששתיות, יוצרות נתונים** אשר קובעות את שיעור התשואה (ROI) של הרובוטים. ככל שרובוטים שיתופיים מתקדמים, אנו צופים שהאפקטורים יתבססו על ענן לשם ניתוח הביצועים.

✍️ **אתגר הנדסי**: אילו מגבלות של EOATs מונעות אתכם מהג automatization? שתפו את האנקורי הצוואר שלכם למטה וنوותר אליכם עם פתרון מותאם אישית!

---

### ✨ **למה זה עובד לקוראים גלובליים**

- **ניווט ויזואלי**: סמלים מדריכים את הקוראים דרך תוכן טכני

- **עומק טכני**: מפרט חדש (תקן ISO, טווח טמפרטורות)

- **התמקדות בפתרון בעיות**: פתרונות שיישומים מיידי

- **אופטימיזציה למנועי חיפוש**: אשכול מילות מפתח (Adaptive Grabber, ISO 16086,