Global medical robot market size will exceed US$28.9 billion in 2025

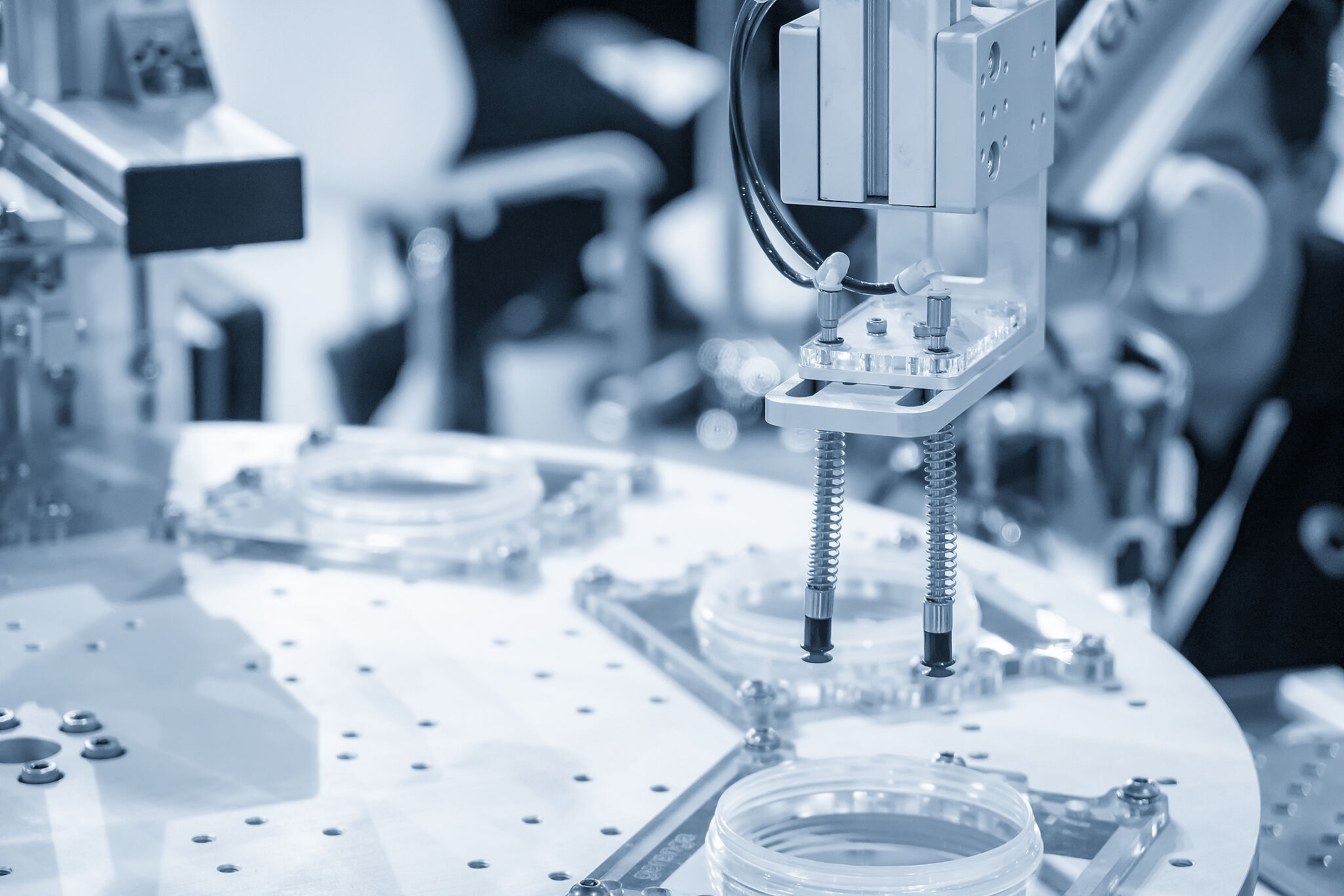

The global medical industry faces the dual challenges of contamination control failure (an average of 32,000 device-related infections per year) and manual operation errors (precision assembly error rate > 5%). Vacuum pneumatic suction cups become the "sterile hands" of medical clean rooms through non-contact adsorption + biocompatible materials - the global medical robot market will exceed $28.9 billion in 2025 (GlobalData forecast), with the penetration rate of vacuum technology exceeding 35%.

Precision operation of drug packaging

Technological breakthroughs:

Micropore array suction cup: adsorbs 0.1mm thick drug foil without wrinkles (vacuum degree ±0.01Bar closed-loop control)

Anti-static patent: static value of handling freeze-dried powder bottles <5V (much lower than the 50V limit specified in EP 8.0)

Adaptation to emerging markets (such as Southeast Asia):

▶ Fluorosilicone rubber suction cup for high temperature and high humidity environment (life guarantee at 35℃/80%RH).

▶ Simple calibration module: to cope with voltage fluctuation (±25%) areas.

Contamination recall cost: $3.8 million per year for manual system → $450,000 for suction cup system.

Maintenance efficiency: Modular suction cup replacement time < 3 minutes (traditional fixtures take 45 minutes).

▶ Quality improvement dimension

Particle contamination rate: from 12 PPM to 0.5 PPM.

Equipment assembly qualification rate: 98.2% → 99.97%.

▶ Economic benefit dimension

Labor cost savings: 70% reduction in clean room personnel.

Reduced insurance costs: 40% reduction in medical malpractice premiums.

▶ Sustainability dimension

Sterilization energy consumption reduction: 65% reduction in hydrogen peroxide consumption.

Material recycling: Medical silicone suction cups are 100% recyclable (UL ECVP certified)

Conclusion: The underlying infrastructure of smart healthcare

Vacuum pneumatic suction cups are evolving from physical handling tools to medical quality data portals: