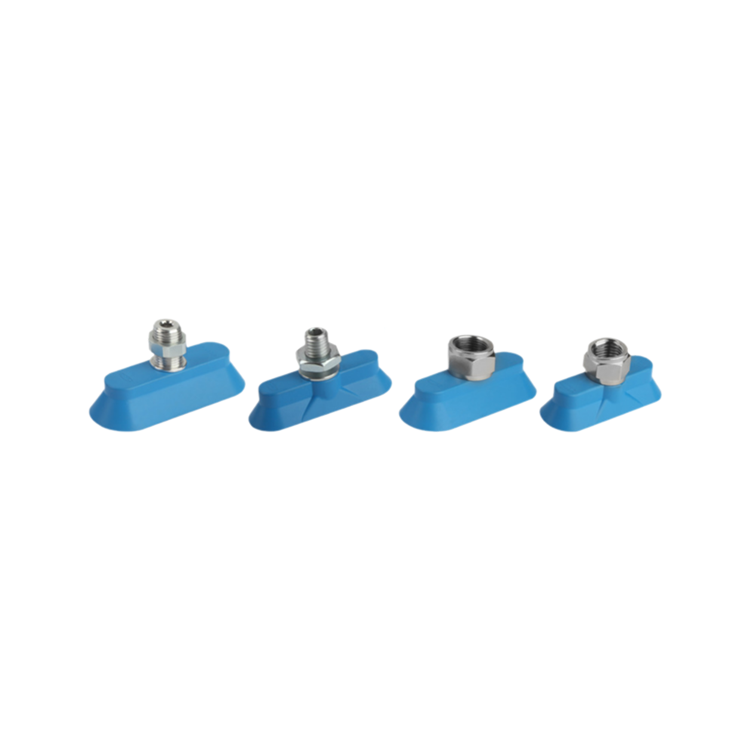

GJHM--Integrated vacuum cup replacement sponge

Materials

- Conductive polyurethane matrix material

- Nano carbon black additives

- Microporous surface treatment

Implementation standards

- ISO 21360-3

- FDA 21 CFR 177.2600

- IEC 61340-5-1

- REACH Annex XVl

- Product Showcase

- 3D Preview

- Description

- Inquiry

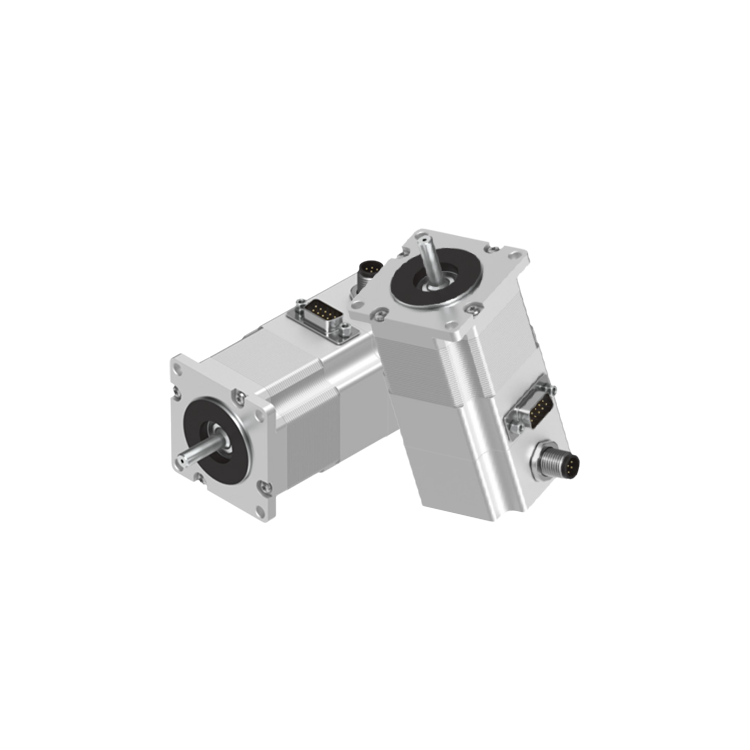

- Related Products

SOVE

The integrated vacuum cup replacement sponge is based on a nano-scale open-cell foaming structure and has leading performance in precision handling. Its gradient density design not only provides a 99.8% vacuum seal retention rate, but is also specially designed for photovoltaic silicon wafer transmission, curved glass gripping, and aseptic packaging production lines, ensuring a deformation control accuracy of ±0.05mm even when subjected to a continuous negative pressure shock of 15kPa.

It is widely used in 🤖 ISO 9288 robot vacuum gripping systems for automated handling (adsorption response <80ms), 🔌 IPC-610 SMT placement machine component suction for electronic manufacturing (accuracy ±0.05mm), and 📦 ASTM D4169 high-speed case packing machine suction cup groups for packaging machinery (beat ≥60cpm), achieving breakthroughs in multi-scenario high-robustness adsorption technology in the field of industrial automation.

1. About 3D models and technical parameters:

"If you need to obtain, please contact us by email."

2. About price consultation:

"If you need to obtain, please get in touch with us. We will provide the most suitable quotation plan."

Description

- Stable adsorption force.

- Strong compression rebound rate.

- Self-diagnosis function.

- AR = Abrasion Resistance

- OR=Oil Resistance

- CS=Compression Set Resistance