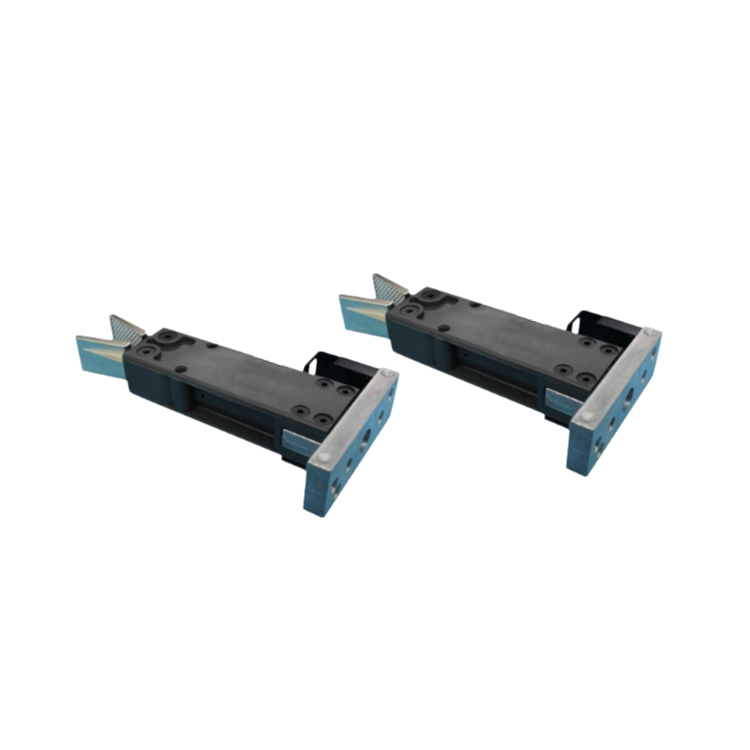

GHAMO--Gate Clamp

Materials

- 061-T6 aviation aluminum main frame

- DC53 Cold Working Die Steel Clamping Module

Implementation standards

- ISO 16090-1

- ISO 9227

- FDA 21 CFR 177.2600

- Sellingpoint

- Product Show

- 3D Preview

- Inquiry

- Related Products

SOVE

The nozzle fixture relies on a high-rigidity modular design and is highly efficient in automated injection molding production. Its multi-axis synchronous drive structure not only achieves 0.01 mm-level repeat positioning accuracy, but is also widely used in automotive lampshade injection molding, medical consumables nozzle separation, and 3C product shell molding, especially in 200℃ high-temperature mold clamping scenarios to maintain 20kN constant pressure shear stability.

It is widely used in the manufacture of optical lenses/medical catheters in precision injection molding, connector PIN needle molding in micro die-casting, and the EMC material handle removal process in conductor packaging. It also has significant application value in other industrial fields.

Description

- Used to remove product gate waste automatically.

- A key auxiliary device in the injection molding process.

- HE = High Temperature Polyurethane

- AR = Abrasion Resistance

- OR=Oil Resistance

- CP=Corrosion Protection

1. About 3D models and technical parameters:

"If you need to obtain, please contact us by email."

2. About price consultation:

"If you need to obtain, please contact us. We will provide the most suitable quotation plan."