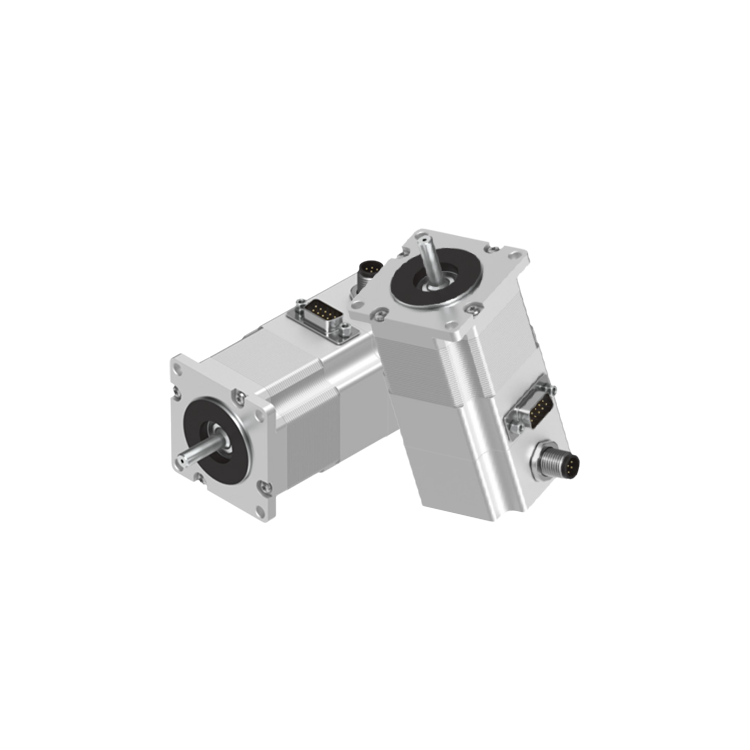

GGV--Vacuum generator

Materials

- Anodized aluminum alloy main structure

- Stainless steel 304 injection unit

- Engineering plastic vacuum chamber

Implementation standards

- ISO 6358:2010

- RoHS 2 (2011/65/EU)

- ISO 3744:2010

- Product Showcase

- 3D Preview

- Description

- Inquiry

- Related Products

SOVE

The vacuum generator has excellent performance in precision adsorption scenarios due to its multi-stage Venturi tube flow channel structure. Its turbulence suppression design not only provides a stable vacuum of -95kPa within 0.18 seconds, but is also widely used in dust-free environments such as semiconductor wafer transmission, medical consumables sorting, and flexible screen bonding, and is particularly capable of ±0.05kPa vacuum stability control under 15Hz high-frequency start-stop conditions.

It is widely used in the integration of micro-stress plastic components and grasping of precision electronic components in light industrial assembly, high-speed visual positioning labeling and adaptive processing of multi-specification bags in packaging machinery, as well as modular assembly lines for 3C products and intelligent sorting systems for micro parts in the field of light automation, and has outstanding technical application value in the field of high-end manufacturing.

1. About 3D models and technical parameters:

"If you need to obtain, please contact us by email."

2. About price consultation:

"If you need to obtain, please get in touch with us. We will provide the most suitable quotation plan."

Description

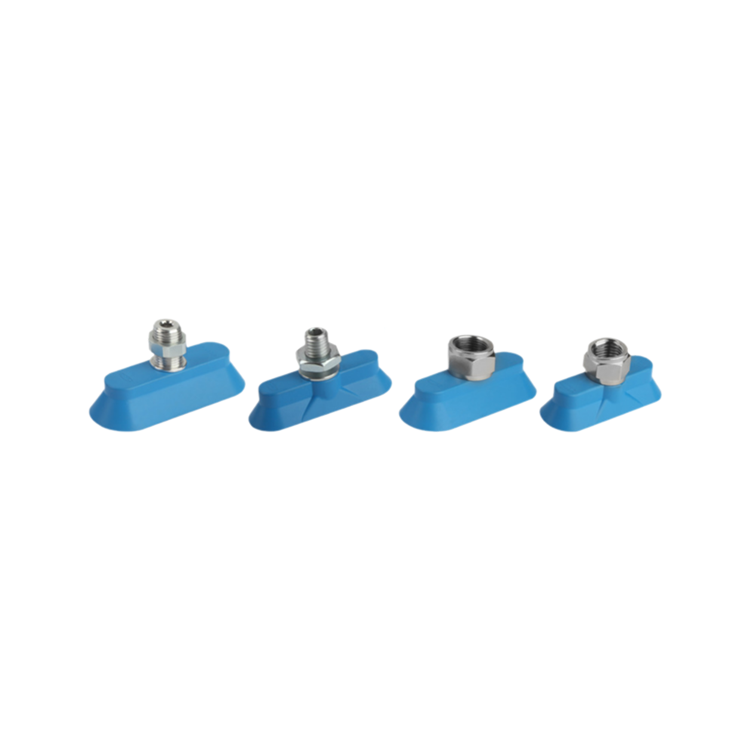

- Straight-through airflow design.

- Single point fixed installation.

- Anti-clogging nozzle design.

- AR = Abrasion Resistance

- OR=Oil Resistance

- HR=Heat Resistance