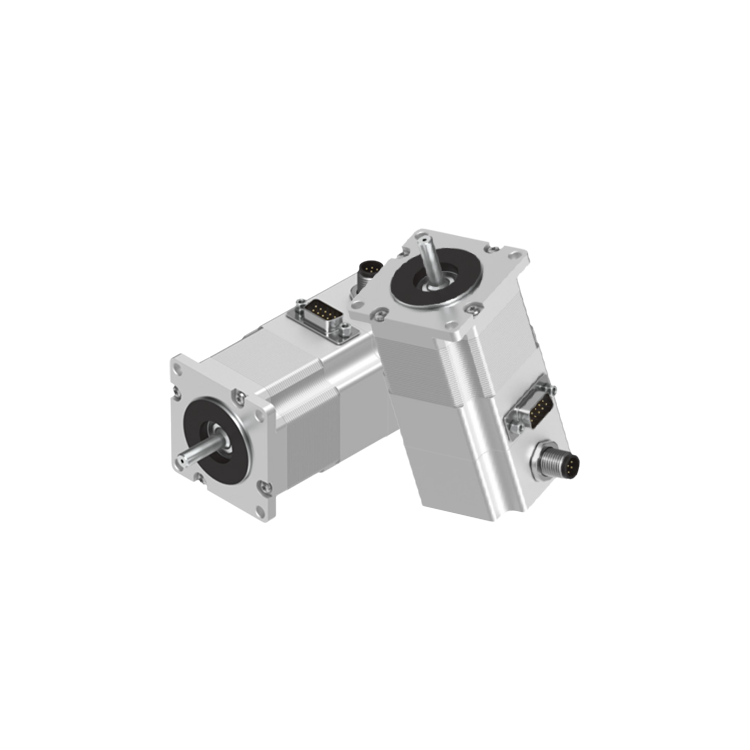

GDLPB6C--Robot fixture signal box

Materials

- Die-cast aluminum alloy housing

- FR-4 fiberglass circuit board

- PUR mixed material cable sheath

Implementation standards

- EN 60204-1

- ATEX II 3G Ex ec IIC T4

- IEC 60068-2-6

- RoHS 3 (EU 2015/863)

- Product Showcase

- 3D Preview

- Description

- Inquiry

- Related Products

SOVE

The robot fixture signal box is based on high-density integrated circuits and multiple electromagnetic shielding structures, and has leading stability in the field of industrial robot terminal signal transmission. Its modular quick-plug interface not only provides millisecond-level signal synchronization capabilities, but is also dedicated to fixture clamping state feedback, visual positioning system triggering, and force control sensor signal conditioning, ensuring ±0.1ms signal synchronization accuracy even in a 20kV/m strong electromagnetic interference environment.

As a multi-domain signal management hub, it is deeply integrated into the 🤖 millisecond-level signal transmission system of the robot's end quick-change device (signal delay <0.5ms | bit error rate <10⁻⁹), the high-frequency pressure monitoring network of the ⚡ welding fixture (sampling rate ≥10kHz | linearity ±0.05%FS), and the multi-source sensor signal fusion platform of the 📊 inspection tooling (channel capacity ≥128 | signal-to-noise ratio >120dB), to achieve precise coordination of industrial field-level signal chains.

1. About 3D models and technical parameters:

"If you need to obtain, please contact us by email."

2. About price consultation:

"If you need to obtain, please get in touch with us. We will provide the most suitable quotation plan."

Description

- Multi-protocol compatible.

- Diagnostic function.

- Hot-swappable design.

- OR=Oil Resistance

- CR=Chemical Resistance

- EMI=Electromagnetic lmmunity