GBV--Vacuum generator

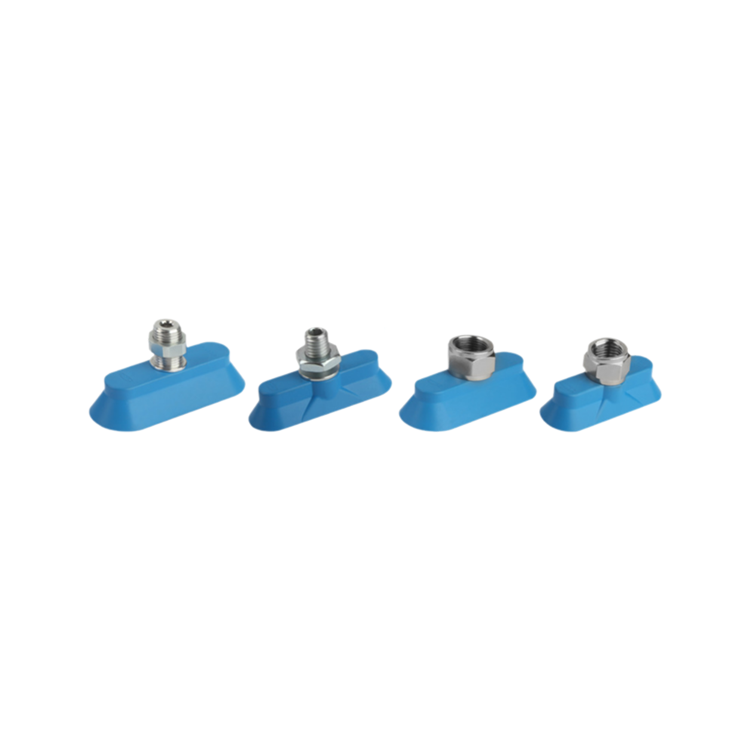

Materials

- Anodized aluminum alloy main structure

- Triple hardened stainless steel nozzle assembly

- Precision brass nickel-plated vacuum chamber

Implementation standards

- ISO 21360-1

- ISO 20140

- RoHS 2.0 (EU) 2015/863

- Product Showcase

- 3D Preview

- Description

- Inquiry

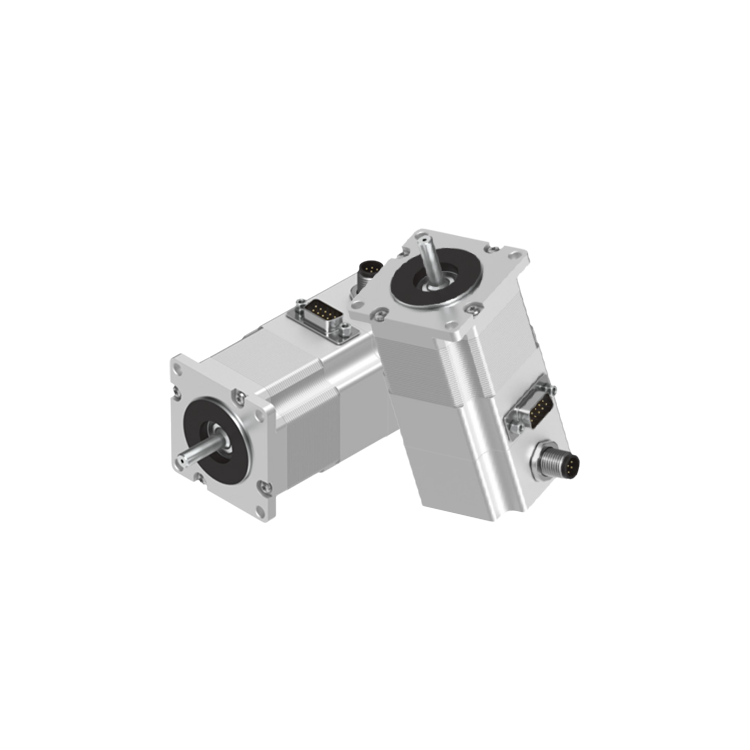

- Related Products

SOVE

The multi-stage vacuum generator relies on the Venturi tube series boosting process and performs excellently in the field of high-efficiency vacuuming. Its energy recovery design not only achieves the establishment of -100kPa ultimate vacuum within 0.4 seconds, but is also widely used in semiconductor etching chambers, lithium battery packaging lines, and medical sterilization equipment, especially maintaining a vacuum stability of ±0.15kPa under 24/7 continuous operation conditions.

It is widely used in wafer vacuum transmission and chip packaging precision positioning in semiconductor manufacturing, large plate non-destructive gripping systems in heavy machinery, and wound negative pressure treatment systems in medical equipment. It also has significant application value in other industrial fields.

1. About 3D models and technical parameters:

"If you need to obtain, please contact us by email."

2. About price consultation:

"If you need to obtain, please get in touch with us. We will provide the most suitable quotation plan."

Description

- Modular nozzle design.

- Multi-stage injection technology.

- The vacuum degree is precisely controlled.

- AR = Abrasion Resistance

- OR=Oil Resistance

- HR=Heat Resistance