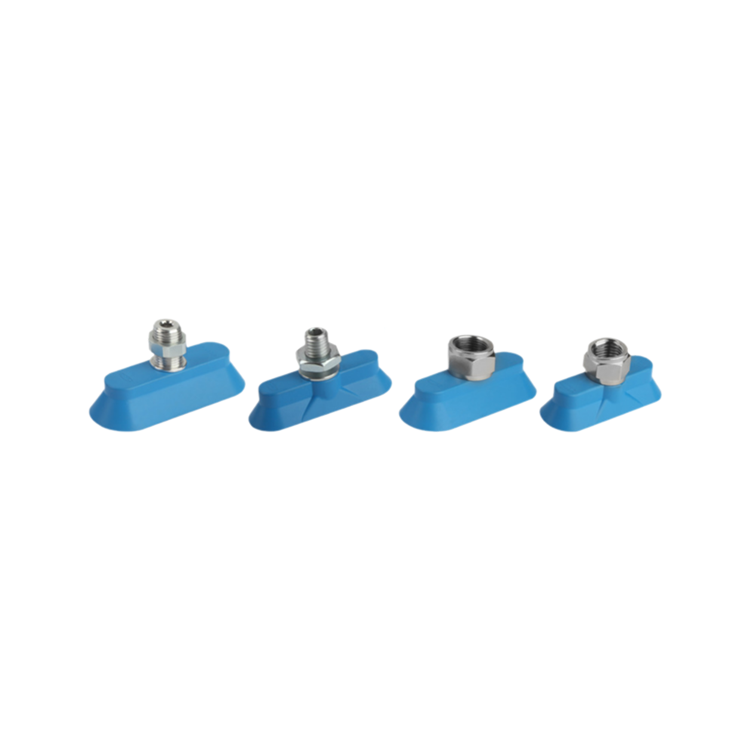

G1615--Nozzle fixture

Materials

- S45C medium carbon steel body

- SKD11 die steel jaws

Implementation standards

- ISO 16090

- EUROMAP 15

- ANSI B151.1

- RoHS 2.0

- Product Showcase

- 3D Preview

- Description

- Inquiry

- Related Products

SOVE

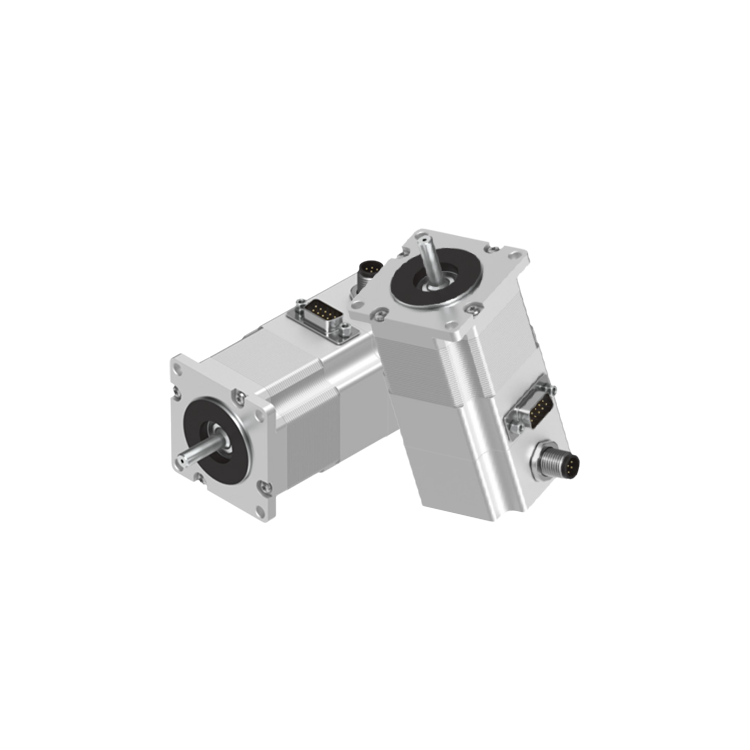

The nozzle fixture relies on a high-rigidity modular design and is highly efficient in automated injection molding production. Its multi-axis synchronous drive structure not only achieves 0.01 mm-level repeat positioning accuracy, but is also widely used in automotive lampshade injection molding, medical consumables nozzle separation, and 3C product shell molding, especially in 200℃ high-temperature mold clamping scenarios to maintain 20kN constant pressure shear stability.

It is widely used to remove the gates of plastic parts in injection molding, separate alloy part handles in die-casting production, and process precision injection-molded parts of medical consumables. It also has important application value in other fields.

1. About 3D models and technical parameters:

"If you need to obtain, please contact us by email."

2. About price consultation:

"If you need to obtain, please contact us. We will provide the most suitable quotation plan."

Description

- Used to remove product gate waste automatically.

- A key auxiliary device in the injection molding process.

- AR = Abrasion Resistance

- OR=Oil Resistance