Unlocking Efficiency: A Comprehensive Guide to Solenoid Valves and Their Applications

In today’s fast-paced industrial landscape, maximizing efficiency is essential for success. One often-overlooked component in achieving operational excellence is the solenoid valve. These handy devices play a critical role in automating control processes across various applications, from simple household systems to complex manufacturing setups. Understanding how solenoid valves work can empower you to make informed decisions that streamline operations, reduce downtime, and optimize energy usage. In this comprehensive guide, we'll dive deep into the mechanics and functionality of solenoid valves, explore their diverse applications, and highlight key considerations for choosing the right type for your needs. Whether you are an engineer, a technician, or a DIY enthusiast, unlocking the potential of solenoid valves can significantly enhance your operational efficiency and drive your projects towards success. Join us as we unlock the secrets of solenoid valves and discover how they can transform your system's performance.

How Solenoid Valves Work

Solenoid valves are electromechanical devices that control the flow of liquid or gas within a system. At the heart of each solenoid valve is an electromagnetic coil, which creates a magnetic field when electrical current passes through it. This magnetic field actuates a plunger or armature, moving it to either open or close the valve. Essentially, the solenoid valve functions as an automated gatekeeper, regulating fluid movement based on electrical signals.<

The operation of solenoid valves is straightforward yet highly efficient. When the coil is energized, the magnetic field pulls the plunger to open the valve, allowing fluid to pass through. Conversely, when the coil is de-energized, a spring forces the plunger back to its original position, closing the valve and halting fluid flow. This binary mechanism offers precise control over fluid dynamics, making solenoid valves indispensable in automation systems.<

Different solenoid valves operate on various principles, but all share the common feature of using electromagnetic force for control. Whether it’s a direct-acting valve with a straightforward design or a pilot-operated valve that leverages fluid pressure for movement, the core functionality remains centered around electromagnetic activation. Understanding this principle is crucial for recognizing how solenoid valves can be effectively utilized in diverse applications.<

Types of Solenoid Valves

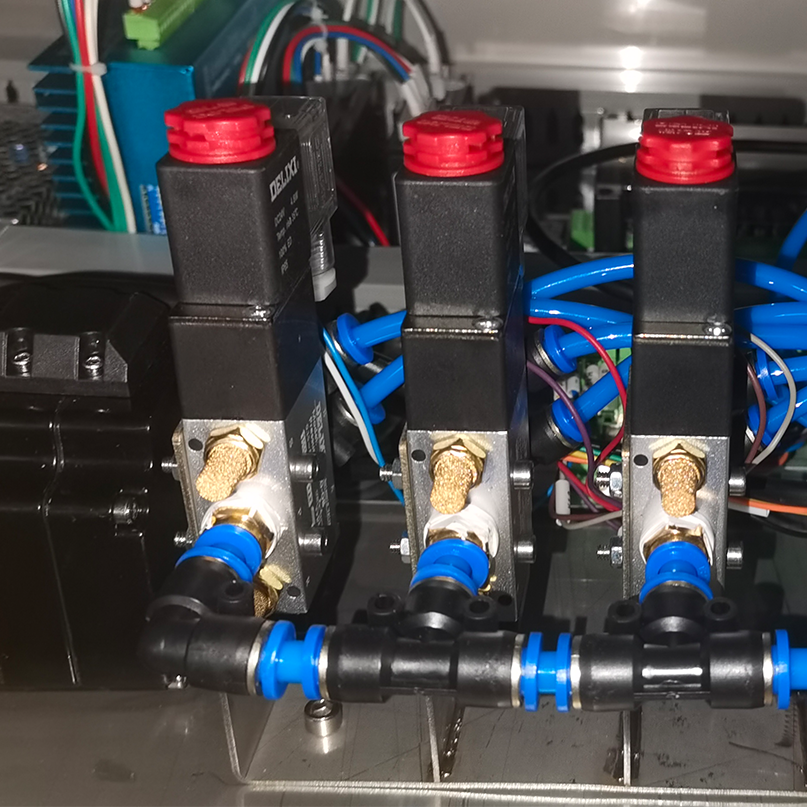

Solenoid valves come in several varieties, each tailored for specific purposes and operational environments. The most common types include direct-acting, pilot-operated, two-way, three-way, and four-way solenoid valves. Direct-acting valves are simple in design and directly control fluid flow by moving the plunger. They are ideal for low-pressure applications and systems requiring quick response times.<

Pilot-operated solenoid valves, on the other hand, utilize system pressure to assist in valve operation. These valves are particularly useful in high-pressure environments where direct-acting valves may not be sufficient. The pilot-operated mechanism ensures that the valve can handle substantial fluid flow without compromising performance.<

Additionally, the configuration of solenoid valves can vary significantly. Two-way valves control fluid flow in a single direction, while three-way valves manage flow between two outlets. Four-way solenoid valves are even more versatile, allowing fluid to move between multiple paths for complex control scenarios. Each type has its unique advantages, making it essential to choose the right design for your specific application.<

Understanding Solenoid Valves

Solenoid valves are electromechanically operated valves that control the flow of liquids or gases. At the heart of a solenoid valve is the solenoid itself—a coil of wire that, when energized, creates a magnetic field. This magnetic field then actuates a plunger or piston, opening or closing the valve. The basic principle is straightforward, yet the range of applications and functionalities these valves offer is vast and intricate. <

The construction of solenoid valves typically involves a body containing an orifice through which the medium flows, a solenoid coil, and a plunger or piston. When the solenoid coil is energized by an electric current, it generates a magnetic field, pulling the plunger either up or down, depending on the design. This movement either opens or closes the orifice, thereby regulating the flow of the medium. The simplicity of this mechanism belies its versatility and efficiency in controlling fluid dynamics. <

One of the key advantages of solenoid valves is their rapid response time. The transition from an open to a closed state (or vice versa) can happen in milliseconds, making them ideal for applications requiring precise control. Furthermore, solenoid valves are available in various configurations—such as normally closed, normally open, and bistable—each suited to different operational needs. This adaptability ensures that solenoid valves can be efficiently integrated into a wide array of systems, from household appliances to industrial machinery. <

Types of Solenoid Valves

Solenoid valves come in different types, each designed to meet specific requirements. The most common types are direct-acting, pilot-operated, and proportional solenoid valves. Each type has unique functional characteristics that make it suitable for different applications. <

Direct-acting solenoid valves operate by directly lifting the valve seat using the magnetic force generated by the solenoid. These valves are simple in design and are typically used for low-flow and low-pressure applications. They are ideal for systems where quick response times are essential, such as in medical devices and small-scale automation systems. <

Pilot-operated solenoid valves, on the other hand, use the solenoid to control a pilot valve that in turn controls the main valve. This design allows them to handle higher pressures and flow rates compared to direct-acting valves. Pilot-operated valves are commonly used in larger industrial systems, such as water treatment plants and HVAC systems, where the ability to manage substantial fluid flows is crucial. <

Proportional solenoid valves are designed to provide variable control over the flow rate. Instead of simply switching between fully open and fully closed states, these valves can modulate the flow based on the input signal. This makes them ideal for applications requiring precise control over fluid dynamics, such as in automotive fuel injection systems and industrial process control. <

Key Benefits of Using Solenoid Valves

One of the primary advantages of solenoid valves is their ability to provide rapid and reliable control over fluid flow. Their quick response time and precise operation reduce the risk of errors and inefficiencies in automated systems. This responsiveness is particularly beneficial in applications where timely fluid regulation is critical, such as in medical devices or industrial manufacturing processes.<

Solenoid valves also offer significant energy savings. Since they only require electrical power when changing states, they consume minimal energy compared to continuously powered alternatives. This intermittent energy usage not only lowers operational costs but also contributes to a more sustainable and environmentally friendly system.<

Moreover, solenoid valves are compact and easy to integrate into existing systems. Their small footprint allows for installation in tight spaces, making them suitable for a wide range of applications. The simplicity of their design translates to lower maintenance requirements, reducing downtime and ensuring consistent performance over long periods.<

Common Applications of Solenoid Valves

Solenoid valves are ubiquitous in various industries, highlighting their versatility and importance. In the automotive sector, they control fuel injection systems, ensuring precise delivery of fuel to the engine for optimal performance. This application underscores the reliability and precision that solenoid valves bring to highly demanding environments.<

In the medical field, solenoid valves are crucial components in devices such as dialysis machines and ventilators. Their ability to regulate fluid flow with high accuracy is vital for patient care and treatment outcomes. By automating fluid control, solenoid valves enhance the functionality and safety of medical equipment.<

Manufacturing processes also benefit significantly from solenoid valves. They are used in assembly lines to control the movement of liquids, gases, and even granular materials. This automation streamlines operations, improves efficiency, and reduces the likelihood of human error, ultimately leading to higher productivity and better product quality.<

Selecting the Right Solenoid Valve for Your Needs

Choosing the appropriate solenoid valve for your application involves considering several factors. First, assess the type of fluid or gas that the valve will control. Different solenoid valves are designed to handle specific substances, and compatibility is crucial to ensure safe and efficient operation. For instance, certain valves are built to withstand corrosive materials, while others are optimized for high-pressure environments.<

Next, evaluate the operating conditions such as temperature, pressure, and flow rate. These parameters will influence the valve's performance and durability. Select a valve that can endure the environmental conditions of your application without compromising functionality. Pilot-operated valves, for instance, are better suited for high-pressure systems, whereas direct-acting valves are ideal for low-pressure scenarios.<

Additionally, consider the electrical specifications of the solenoid valve. The coil voltage and current ratings must align with your system's power supply to ensure proper operation. Incorrect electrical specifications can lead to inefficient performance or even damage to the valve. By carefully matching the solenoid valve to your system requirements, you can achieve optimal efficiency and longevity.<

Installation and Maintenance Tips for Solenoid Valves

Proper installation is paramount to the performance of solenoid valves. Begin by ensuring that the valve is correctly oriented according to manufacturer guidelines. Incorrect orientation can impede fluid flow and lead to operational issues. Additionally, verify that all connections are secure and free from leaks before powering the system.<

Routine maintenance is essential to preserve the functionality of solenoid valves. Periodically inspect the valve for signs of wear or damage, especially in high-usage applications. Clean the valve and surrounding components to prevent debris from obstructing fluid flow. Regular maintenance not only extends the lifespan of the valve but also ensures consistent performance.<

In case of malfunction, refer to the troubleshooting section of the manufacturer’s manual. Common issues include coil failure, blocked ports, and worn-out seals. Address these problems promptly to avoid prolonged downtime. Keeping spare parts on hand, such as replacement coils and seals, can expedite repairs and minimize disruption to operations.<

Troubleshooting Common Solenoid Valve Issues

Despite their reliability, solenoid valves can encounter issues that impede their performance. One common problem is coil failure, often caused by electrical surges or prolonged exposure to high temperatures. If the coil is damaged, the valve will not actuate, leading to disrupted fluid control. Regularly check the coil’s condition and replace it if necessary to maintain smooth operation.<

Another frequent issue is blocked ports, which can result from debris or sediment buildup. A blocked port restricts fluid flow and can cause the valve to malfunction. Regular cleaning and maintenance can prevent blockages and ensure that the valve operates efficiently. Using filters in the system can also mitigate the risk of debris accumulation.<

Worn-out seals are another concern. Over time, seals can degrade due to constant exposure to fluid and pressure variations. Damaged seals can lead to leaks and inefficient valve performance. Inspect seals regularly and replace them as needed to prevent fluid loss and maintain optimal functionality. Proactive maintenance is key to addressing these common issues and ensuring the longevity of your solenoid valves.<

Innovations in Solenoid Valve Technology

The field of solenoid valve technology is continuously evolving, with innovations aimed at enhancing performance and efficiency. One notable advancement is the development of smart solenoid valves equipped with sensors and microprocessors. These valves can monitor their own performance, detect anomalies, and communicate data to centralized control systems for proactive maintenance and optimization.<

Another significant innovation is the integration of materials science into valve design. Modern solenoid valves now incorporate advanced materials that offer superior resistance to corrosion, wear, and extreme temperatures. These materials extend the lifespan of the valves and improve their reliability in demanding applications.<

Furthermore, the miniaturization of solenoid valves has opened new possibilities in various fields. Compact, high-performance valves are increasingly used in medical devices, aerospace components, and consumer electronics. This miniaturization trend not only enhances the versatility of solenoid valves but also enables their use in applications where space constraints are critical.<

Conclusion: The Future of Solenoid Valves in Various Industries

As industries continue to prioritize efficiency and automation, the role of solenoid valves will only become more prominent. Their ability to provide precise control over fluid dynamics makes them indispensable in modern systems. The ongoing advancements in solenoid valve technology will further enhance their performance, reliability, and application scope.<

Future developments may see solenoid valves integrated into increasingly sophisticated smart systems, capable of self-diagnosis and adaptive control. These innovations will drive operational excellence, reduce maintenance costs, and optimize energy usage across various industries. The versatility and efficiency of solenoid valves position them as key components in the future of automation.<

In conclusion, understanding and leveraging the capabilities of solenoid valves can significantly transform your system's performance. Whether you are streamlining manufacturing processes, enhancing medical devices, or improving energy management, solenoid valves offer a pathway to greater efficiency and success. As technology progresses, solenoid valves will continue to unlock new levels of operational excellence, driving industries towards a more efficient and automated future.<

Table of Contents

- How Solenoid Valves Work

- Types of Solenoid Valves

- Understanding Solenoid Valves

- Types of Solenoid Valves

- Key Benefits of Using Solenoid Valves

- Common Applications of Solenoid Valves

- Selecting the Right Solenoid Valve for Your Needs

- Installation and Maintenance Tips for Solenoid Valves

- Troubleshooting Common Solenoid Valve Issues

- Innovations in Solenoid Valve Technology

- Conclusion: The Future of Solenoid Valves in Various Industries