Top 5 Benefits of Using Pneumatic Cylinders in Manufacturing Processes

Pneumatic cylinders are handy devices that allow things to move fast and also carry a punch. They run on compressed air and generate force — both huge advantages in many manufacturing operations. One major advantage of pneumatic cylinders is that they can move things quickly and precisely. That means factories are able to produce items quicker and with higher standards.

Benefits

Pneumatic Cylinders Are Easy to Service Another great feature of pneumatic cylinders is the fact that they’re cheap, and they’re a money-saving option when it comes to their long-lasting performance. This helps factories save money in the long run. They don’t cost much to purchase or install, and have relatively few moving parts. This makes them simpler to repair if something goes wrong, resulting in lower repair costs. Pneumatic cylinders are a common choice for many manufacturers as they help in enhancing work without the need for spending lots of money.

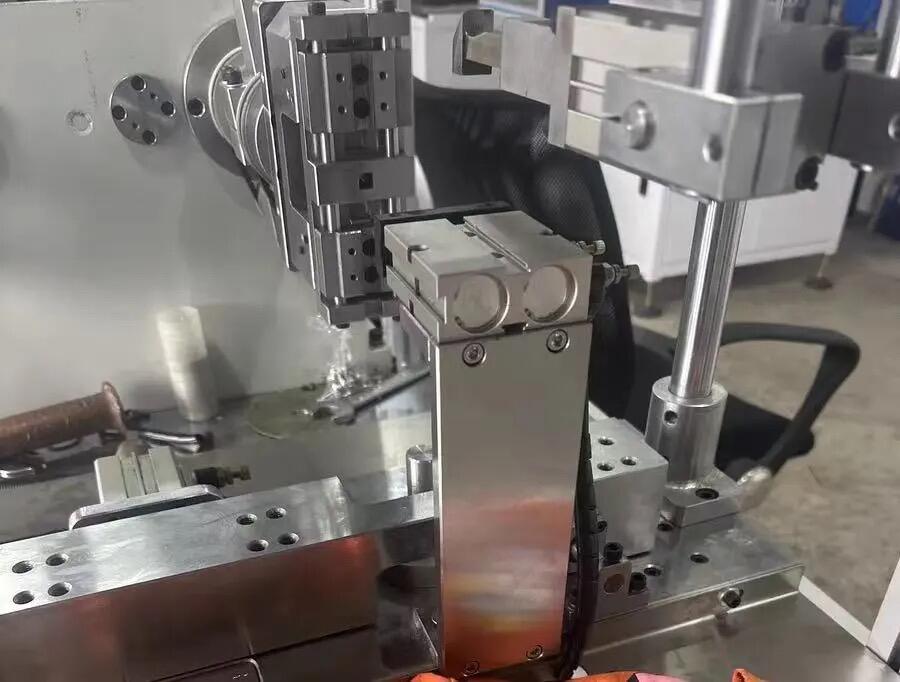

You’ll find pneumatic cylinders in a wide range of manufacturing jobs — in building cars or packaging food, for instance. They can lift, press, pull and rotate objects. For instance, they play a role in assembling car parts on a production line or packing food products in a factory. Air cylinders assist in production line processes for manufacturing.

Advantages

These Pipe connectors have very accurate motion, which enables their user to take things exactly where they need to go. That’s crucial for manufacturers, who need to maintain quality and safety standards. Pneumatic cylinders ensure that companies have the type of consistent quality to expect in their products.

Pneumatic cylinders can also be used in factories and serve as a safe option for workers who do not want to be involved in an accident. They don’t rely on electricity, unlike some other machines, so you can’t get a shock. They are designed to be sturdy and durable — so they are less likely to break down. Maintaining safety That when it comes to safety, pneumatic cylinders help ensure everyone is safe on the job.

Summary

In short, Air pneumatic cylinder are an ideal solution to use in production because of all the advantages. They travel fast and come cheap, and are enabling machines in factories to work better and faster. Pneumatic cylinders make businesses increase its work quality and produce high-quality products all in all by operating in a safe and controlled manner. Pneumatic cylinders help manufacturers work efficiently and keep their employees safe.