⚙️ Core architecture and working principle

1. Contact interface layer

Robotic fingers: high-carbon steel structure, capable of handling geometric payloads (e.g. automotive gears), with a clamping force of up to 500N

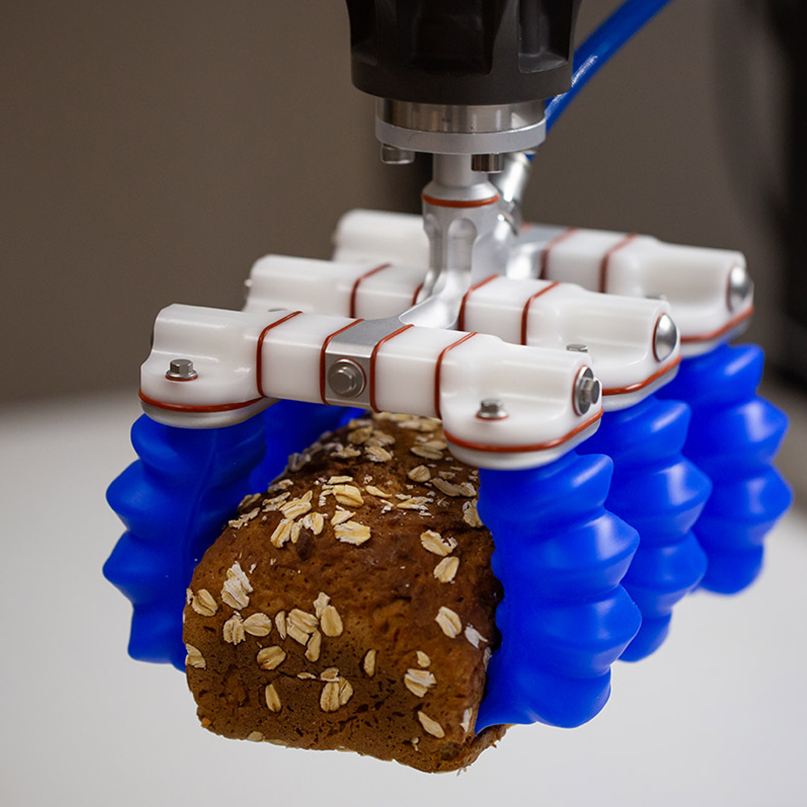

Flexible gripper: food-grade silicone material, with a force control accuracy of ±0.1N, suitable for delicate operations (e.g. strawberry picking)

Vacuum end effector: multi-stage suction system, capable of handling 0.5-50kg flat objects (e.g. glass panel installation)

Electromagnetic module: rare earth magnet array, adjustable suction force, up to 50-2000kg (e.g. steel plate handling)

2. Drive system

Pneumatic drive: 0.6-1.0MPa compressed air, response time less than 0.3s (e.g. electronic product sorting line)

Servo drive: motor equipped with harmonic reducer, with an accuracy of ±0.02mm repeatability (semiconductor packaging)

Hydraulic power unit: 35MPa fluid system, supports 10 Payloads over tons (shipbuilding applications)

3. Intelligent control nodes

3D vision guidance: 120fps point cloud processing for random picking

Tactile feedback: strain gauge monitoring, programmable safety thresholds

Edge AI processing: real-time adaptive grasping strategies for new objects

? Application categories

Industrial robot grippers

Automobile welding production line: integrated 6-axis manipulation, door panel positioning within 2 seconds

Semiconductor processing: Class 10 clean room compliant with ESD protection

Collaborative systems

Safety architecture: dual-mode force limitation, collision response time 15ms

Food processing: AI vision-guided flexible fingers, processing 4,000 baked goods per hour

Customized solutions

Medical microgripper: titanium alloy end effector for sub-millimeter container manipulation

Agricultural systems: bionic design with humidity sensing (crop damage rate <0.5%)

? Specific industry applications

Automobile manufacturing

Body-in-white: multi-gripper collaborative control, positioning accuracy of 0.1 mm

Powertrain assembly: Thermal compensation algorithm for 80°C operating deviations

Innovation: Magnetorheological fluid gripper for curved panels

Electronics production

Microcomponent handling: Piezoelectric drive with 0.01N force resolution

Display lamination: Contactless vacuum system for ISO Class 5 cleanliness

Key solution: Shock absorption algorithm for PCB assembly

Perishable logistics

Cold chain operation: Elastomer materials rated at -30°C

Irregular object handling: Deep learning to identify more than 2,000 package contours

Performance: 150,000 operations per day with 0.03% error rate

Heavy industry

Casting applications: Alloy jaw structure rated at 800°C

Large-scale manipulation: Hydraulic synchronization of components with a span of 20 meters

Safety engineering: Triple redundant pressure system with fall protection mechanism

? Quantified operational benefits

Productivity improvement: 40% reduction in automotive production line cycle time

Quality assurance: Assembly force fluctuation ≤2%, yield rate of 99.98%

Return on investment: 300% return in 3 years, maintenance cost is 65% lower than manual labor

Capacity expansion: from micron-level medical device assembly to 100-ton wind turbine blade handling

? Emerging technologies and market development trajectory

Innovation frontier

Smart materials: shape memory alloy self-configuring gripper

Cross-domain integration: tactile feedback and AR remote operation

Autonomous adaptation: reinforcement learning in unstructured environments

Industry indicators

Global market compound annual growth rate of 12.7% (2025-2030)

Collaborative robot penetration rate in automotive electronics 45% 2028

Chinese manufacturers account for 35% of the market share (patent annual growth rate of 40%)