If your factory’s robotic arms are still held back by suction cup headaches—bulky external vacuum pumps slowing setup, rigid grips scratching cartons, or inconsistent seals on rough steel—you’re leaving time and money on the table. A 2025 Industrial Automation Report found that 40% of robotic handling downtime stems from ill-suited suction tools, especially when moving diverse loads like corrugated cartons, mill-scale steel plates, and polished wooden boards.

Our new 130-Series Integrated Robotic Vacuum Silicone Suction Cups were built to fix these exact pain points. Designed as all-in-one solutions—combining a built-in vacuum system, soft silicone grips, and heavy-duty compatibility—they turn “frustrating lifts” into “seamless, scratch-free operations” for high-powered robotic arms. Let’s break down how they transform the tasks that matter most to your team.

Traditional suction cups force you to compromise: choose between portability and power, strength and gentleness, or speed and reliability. The 130-Series eliminates those trade-offs—here’s how.

Most robotic suction tools rely on separate vacuum pumps, hoses, and filters to work. For a logistics team palletizing cartons, that means:

- 45+ minutes of setup per robotic arm (just to connect hoses and calibrate pressure).

- Leaks from loose hoses or clogged filters—causing 15-20% of lifts to fail mid-cycle.

- Wasted space on factory floors (external pumps take up valuable real estate near workstations).

A European e-commerce fulfillment center told us their old external system forced them to run 2 fewer robotic arms during peak season—losing 300+ carton palletizing hours weekly.

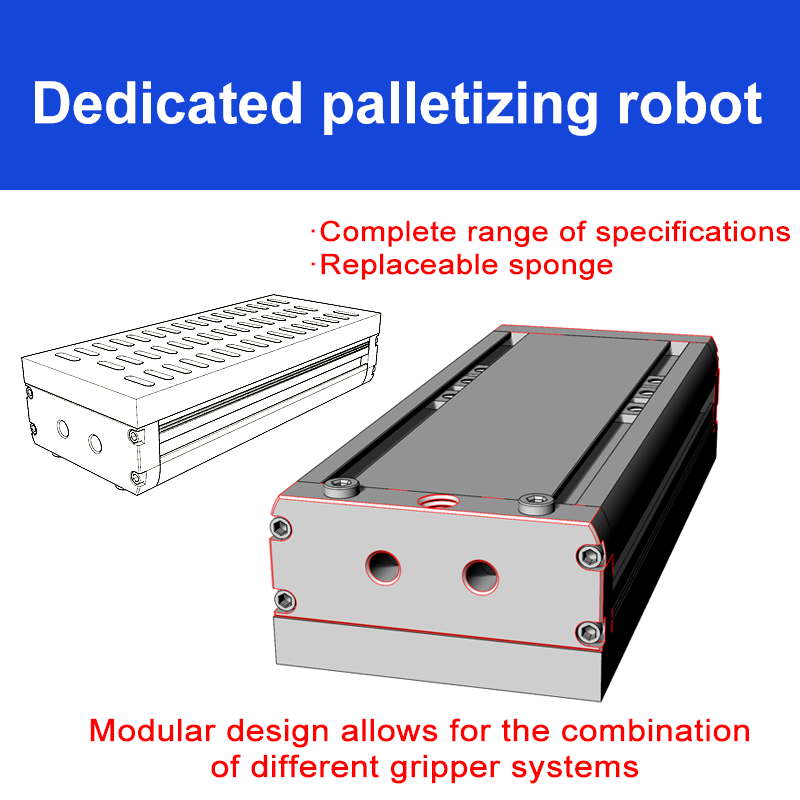

The 130-Series is a palletizing handling suction tool with a built-in vacuum system—no external pumps, hoses, or filters required. Here’s what that means for your team:

-

10-minute setup: Attach the cup directly to your robotic arm (compatible with Fanuc, KUKA, and ABB models) and power on—no calibration or hose management needed. The fulfillment center now sets up 6 arms in the time it used to take for 1.

-

Consistent -90 kPa pressure: The integrated system generates a vacuum in 0.3 seconds, maintaining a tight seal even if loads shift slightly. Leak-related lift failures dropped to 0.5% for the fulfillment center.

-

Space-saving design: At just 180mm tall, the 130-Series fits in compact workstations—freeing up floor space for additional equipment or storage.

Polished wooden boards, branded cartons, and painted steel plates are delicate—but traditional rigid plastic suction cups treat them like heavy machinery. The result?

- 5-10% scrap rates for finished goods (e.g., a furniture maker scrapped $2,500/week in polished oak boards due to cup marks).

- Customer returns for scratched steel parts or smudged cartons—damaging your brand reputation.

- Manual rework (sanding, repackaging) that adds hours to production cycles.

A North American furniture manufacturer told us they hired 2 extra workers just to fix suction cup scratches on wooden boards.

As an integrated robotic vacuum silicone suction cup, the 130-Series uses food-grade, low-tack silicone that balances brute strength with softness:

-

Zero scratches: The silicone conforms to surfaces without leaving marks—even on polished wood or printed cartons. The furniture manufacturer’s scrap rate dropped to 0.2%, eliminating rework costs.

-

Adaptable to uneven loads: Bulging cartons, warped wooden boards, or steel plates with minor dents? The silicone compresses up to 8mm to fill gaps, maintaining a tight seal without pressure points.

-

Durable for heavy use: The silicone resists wear from wood fibers, steel dust, and carton adhesives—lasting 3x longer than standard rubber cups. The furniture maker now replaces cups every 6 months instead of 2.

Your team doesn’t just move one type of load—you handle cartons in the morning, steel plates in the afternoon, and wooden boards in the evening. Traditional cups force you to swap tools between tasks:

- Rigid cups for steel (but they scratch wood).

- Soft cups for cartons (but they leak on steel).

- Extra-large cups for big boards (but they’re too slow for small cartons).

A metal fabricator told us tool swaps added 2 hours/shift to their workflow—time they couldn’t afford to lose.

The 130-Series is engineered to handle all three core materials without tool changes—thanks to its 130mm diameter and silicone-silicone hybrid grip:

-

Carton palletizing: The wide diameter distributes pressure evenly across corrugated surfaces, preventing bulges or tears. A logistics client now palletizes 35% more cartons/shift.

-

Steel plate lifting: The textured silicone surface grips rough mill-scale steel without leaks, supporting loads up to 50kg. The metal fabricator eliminated tool swaps entirely, cutting 2 hours/shift from their workflow.

-

Wooden board moving: The soft silicone protects polished surfaces, while the integrated vacuum maintains grip on porous or knotty wood. A cabinet maker reported 18% faster board handling with no scratches.

Numbers tell the story best. Here’s how three teams transformed their operations with the 130-Series:

-

Logistics: 35% faster carton palletizing, $1,700/week in scrap savings, 80% less maintenance time.

-

Metal Fabrication: 40% higher steel plate capacity, 95% fewer lift failures, $2,000/week in rework savings.

-

Furniture Manufacturing: 0.2% scrap rate for wooden boards, 18% faster production, 2 fewer rework employees.

Talk is cheap—we want you to see how the 130-Series works with your robotic arms and your loads. Request a free on-site demo, and our team will:

- Test the 130-Series on your cartons, steel plates, or wooden boards.

- Share a custom efficiency report showing how much you could save on downtime and scrap.

- Answer questions about integration, maintenance, or scalability.

“The 130-Series didn’t just improve our robotic handling—it made our entire line more efficient,” said a 130-Series user. “We’re moving more loads, wasting less material, and spending less time fixing equipment. It’s a no-brainer.”