# EOAT Ramka ulagichlari: Pnevmatik gripperlar va robot qo'llarni avtomatlashtirilgan ishlab chiqarishda integratsiya qilish

Industry 4.0 davrida avtomatlashtirilgan sexlar yanada samarali, aniq va moslashuvchan bo'lish uchun ildam o'zgarishlarga uchrab ketmoqda. Bu rivojlanishning asosida pnevmatik gripperlar kabi asosiy komponentlar bilan robot qo'llarini birlashtirishda ramka ulagichlar muhim o'rin tutgan bo'lib, qo'lga keltirish vositalari (EOAT) tizimlarini silliq integratsiya qilish yotibdi. Bu maqola EOAT ramka ulagichlari qanday qilib avtomatlashtirish jarayonlarini optimallashtirish, operatsion ko'p tomonlama qobiliyatni oshirish va zamonaviy ishlab chiqarish muhitida maqsadga muvofiq ishlashni rag'batlantirishini ko'rib chiqadi.

## Avtomatlashtirishda EOAT ramka ulagichlarning roli

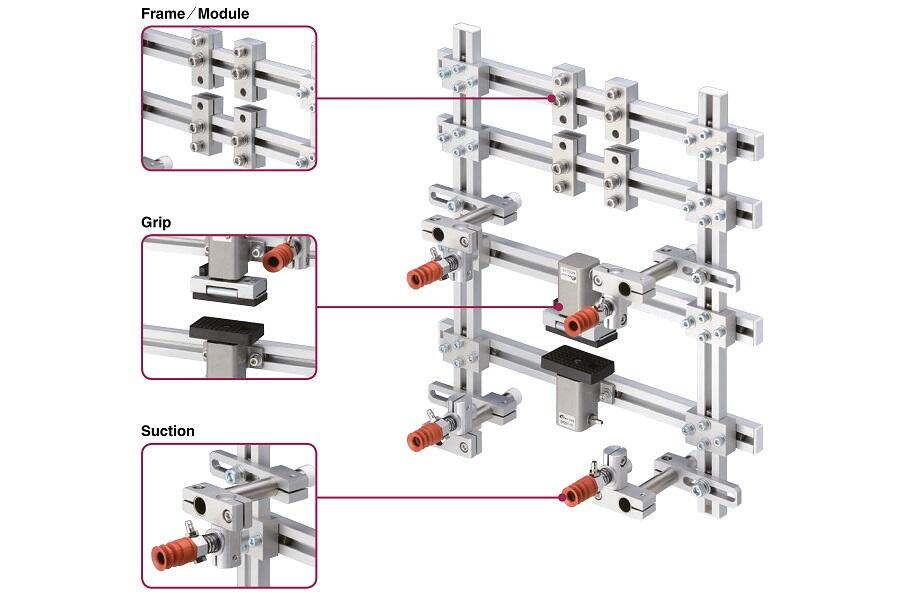

EOAT ramka ulagichlar robot qo'llar va oxirgi effektorlar (masalan, pnevmatik gripperlar, vakuum stakanlar yoki maxsus asboblar) o'rtasidagi mexanik interfeys vazifasini bajaradi. Bu ulagichlar yuqori tezlikdagi ishlab chiqarish tsikllarini davolash qobiliyatiga ega, hamda aniq moslashuvchanlik va takrorlanuvchanlikni kafolatlovchi mustahkam, modulli va moslanuvchan ulanishlarni ta'minlash uchun mo'ljallangan.

Avtomatlashtirilgan ishlab chiqarish joylarida materiallarni qayta ishlashdan tortib murakkab montajgacha bo'lgan vazifalar bajarilganda EOAT ramka ulagichlar quyidagi uchta asosiy muammoga yechim beradi:

- **Moslik**: Xilma-xil robot qo'l modellar va oxirgi effektorlar o'rtasida silliq integratsiyani ta'minlash.

- **Moslanuvchanlik**: Turli ishlab chiqarish talablari uchun tez asboblarni almashtirish imkonini beradi.

- **Chidamlilik**: Mexanik kuchlanish, tebranish hamda chang, sovutuvchi suyuqlik kabi tashqi omillarga chidash qobiliyati.

## Pnevmatik gripperlar bilan hamkorlik: Materiallarni qayta ishlashda anqlik

Pnevmatik ushatorshiklar avtomatlashtirishda tezlik, kuch nazorati va turli xavfli elektronikadan tortib og'ir metall qismlargacha bo'lgan materiallarni qayta ishlash qobiliyati bilan keng qo'llaniladi. EOAT ramka ulagichlari bilan juftlanganda ularning ishlashi quyidagilar orqali oshiriladi:

1. **Kuchaytirilgan moslashuvchanlik**: Ramka ulagichlari pnevmatik ushatorshiklarni daqiqalarda qayta pozitsiyalash yoki almashtirish imkonini beradi, shu bilan birga robot qo'llari ishlash vaqti bekor qilinmasdan turli vazifalarni, masalan, olish, qo'yish yoki saralashni bajarishda o'tish imkonini beradi.

2. **Optimal kuch taqsimoti**: Qattiq, lekin yengil ulagich dizaynlari gripperdan ishchi qismgacha kuchni bir xil tarqatishini ta'minlaydi, shishasi nozik buyumlarning shikastlanish xavfini kamaytiradi hamda og'ir yuklar uchun ushlab turish ishonchliligini saqlab turadi.

3. **Biriktirishni pnevmatik integratsiyasi**: Ko'plab EOAT ulagichlarida havo kanallari mavjud bo'lib, tashqi shlanglarga ehtiyoj qolmaydi. Bu dizaynni soddalashtiradi, gavjumlikni kamaytiradi va yuqori tezlikdagi harakatlarda shlanglarning tashwishi ehtimolini kamaytiradi.

Masalan, avtomobil montaj liniyalarida bu integratsiya pnevmatik gripperlar bilan jihozlangan robot qo'llarini EOAT ulagichlar qo'llab-quvvatlovchi stansiyalarda aniq moslashuvini ta'minlab, tananing panellarini hamda kichik mahkamlagichlarni almashtirish imkonini beradi.

## Avtomatlashtirilgan robot qo'l bilan integratsiya: Operational samaradorlikni oshirish

Avtomatlashtirilgan robot qo'l zamonaviy sexlarning asosiy vositasi bo'lib xizmat qiladi, lekin ularning samaradorligi ularning qo'llab-quvvatlayotgan vositalarga bog'liq. EOAT ramka ulagichlari quyidagi yo'llar bilan ularning to'liq imkoniyatlarini ochadi:

- **Interfeyslarni standartlashtirish**: Robot qo'l brendi yoki modelidan (masalan, artikulyatsion, SCARA yoki hamkorlik qiluvchi robotlar) qat'iy nazar, ramka ulagichlari universal o'rnatish tizimini taqdim etadi, vositalarni integratsiya qilishni soddalashtiradi va texnik xodimlar uchun o'qitish talablari kamaytiradi.

- **Modulyar uskunani qo'llab-quvvatlash**: Biriktirgichlar pneomatik gripperlarni sensorlar, kamerolar yoki moment kalitlari bilan birlashtiruvchi ko'p funksiyali EOAT to'plamlarini o'rnatish imkonini beradi — bu esa robot qo'llariga montaj jarayonida sifat nazoratini o'tkazish kabi murakkab vazifalarni bajarish imkonini beradi.

- **Takrorlanuvchanlikni yaxshilash**: Ramka biriktirgichlarning yuqori aniqlikdagi ishlanishi 3D bosmaxona kabi sohalarda juda kichik nuqsonlar ham qismlar sifatini buzishi mumkin bo'lgan dasturlar uchun muhim bo'lgan vosita pozitsiyasini ta'minlaydi.

Elektronika ishlab chiqarishda bu sinerjiya elektron karta montajida namoyon bo'ladi, unda EOAT bilan biriktirilgan pneomatik gripperlar bilan jihozlangan robot qo'llar ayniqsa bir mikron aniqlikda komponentlarni o'rnatadi, bu esa biriktirgichning barqaror interfeysi hisobiga amalga oshiriladi.

## Haqiqiy dunyoviy dasturlar: Avtomatlashtirilgan ish jarayonlarini shakllantirish

EOAT ramka biriktirgichlar, pneomatik gripperlar va robot qo'llar integratsiyasi sanoatni tubdan o'zgartirmoqda:

- **Logistika va Qadoqlash**: Elektron savdo bajaruvchi markazlarda, vakuumli ushatorsiz EOAT qo'shimcha qurilmalar bilan jihozlangan robot qo'llari turli o'lchamdagi qadoqlarni qayta ishlashda qo'llaniladi. Ramka ulagichlari qutilar va nozik konvertlarni ushovchi qurilmalarni almashtirish imkonini beradi.

- **Oziq-ovqat va Ichimliklar**: Gigienik EOAT ulagichlar ovqat sifatidagi pnevmatik gripperlar bilan juftlanib, mevalarni saralashdan tortib, qadoqlangan mahsulotlarni transportyor lentaga qo'yishgacha bo'lgan jarayonlarni gigienik ushlab turishda qo'llaniladi hamda qat'iy xavfsizlik standartlariga javob beradi.

- **Aerospace Ishlab Chiqarish**: Yuqori mustahkamlikka ega bo'lgan aluminiy yoki titanning EOAT ulagichlari robot qo'llariga pnevmatik gripperlarni mustahkam ulashni ta'minlab, qanot panellariga o'xshash yengil, lekin konstruktsion jihatdan muhim tushkunliklarni aniq boshqarish imkonini beradi.

## EOAT Ramka Ulagichlarni Integratsiya Qilishning Afzalliklari

EOAT ramka ulagichlar, pnevmatik gripperlar hamda robot qo'llarning birlashtirilgan foydalanishidan kelib chiqadigan o'lchanadigan foydalar:

- **Ishlab chiqarishni oshirish**: O'zaro almashtirish vaqtini qisqartirish va 24/7 ishlash imkoniyati yuqori hajmli muhitda ishlab chiqarish tsiklini 30% gacha kamaytiradi.

- **Xarajatlarni tejash**: Modulli jihozlar maxsus robot qo'llar uchun ehtiyojni kamaytiradi, ayni paytda aniqroq sozlash materiallarning yiqilishini kamaytiradi.

- **Ishchilarni xavfsizligi**: Takroriy yoki xavfli vazifalarni (masalan, og'ir narsalarni ko'tarish) avtomatlashtirish ish joyidagi jarohatlarni kamaytiradi, hamkorlik qiluvchi robotlar esa EOAT tizimlari bilan jihozlangan va inson operatorlar bilan xavfsiz tarzda ishlaydi.

- **Kengayish imkoniyati**: Ishlab chiqarish talablari rivojlanib borishiga qarab, korxonalar butun robot tizimini almashtirmasdan EOAT komponentlarini yangilash yoki qayta sozlash orqali investitsiyalarni kelajakka moslashtirishlari mumkin.

## Kelajak tendentsiyalari: EOAT texnologiyasidagi innovatsiyalar

Avtomatlashtirish rivojlanib borishiga qarab, EOAT ramka ulagichlari yangi talablarga javob berish uchun o'zgarib borayapti:

- **Aqlli ulagichlar**: Ulagichlarga o'rnatilgan sensorlar vositasi bilan vosita eskirishini, haroratni va ushlab turish kuchini kuzatib boradi, shu bilan birga IoT integratsiyasi orqali oldindan taxmin qilish va haqiqiy vaqtda sozlash imkonini beradi.

- **Qo'shimcha ishlab chiqarish**: 3D bosmali ulagichlar, alohida sohalarga moslashtirilgan, ular og'irlikni kamaytirish va murakkab geometriyani taklif qiladi, shu bilan birga unumdorlikni yanada optimallashtiradi.

- **Barqarorlik**: Ekologik toza materiallar va energiya tejovchi dizaynlar EOAT tizimlarini global ishlab chiqarishning karbon izini kamaytirishga qaratilgan jahon choralari bilan muvofiq qiladi.

## Xulosa

EOAT ramkali ulagichlar avtomatlashtirilgan sexlar uchun dastlabki bosqichda ahamiyatsiz ko'rinadigan, ammo pnevmatik gripperlar va robot qo'llarning bevosita integratsiyasini ta'minlaydigan muhim elementlardir. Ular moslik, moslanuvchanlik va aniqlikni ta'minlash orqali ishlab chiqaruvchilarga talablarning o'zgarishiga javob berish, ish unumdorligini oshirish va jahon bozorda raqobatbardoshlikni saqlash imkonini beradi. Texnologiyalar rivojlanib borishda, bu ulagichlar sanoat avtomatlashtirish kelajagining asosiy tashabbuskorlarini shakllantirishda davom etadi - bu yerda samaradorlik, ko'p tomonlama foydalanish va yangiliklar birlashadi.