GDLGP--Klamër amortizuese

Materialet

- Cilindër amortizues prej aliazhi të fortë të aluminit

- shufër amortizuese prej eliku aliazhu 42CrMo4

Normat e zbatimit

- ISO 13849-1 PL e

- EN 45545-2 HL3

- IEC 60068-2-14

- ISO 10763

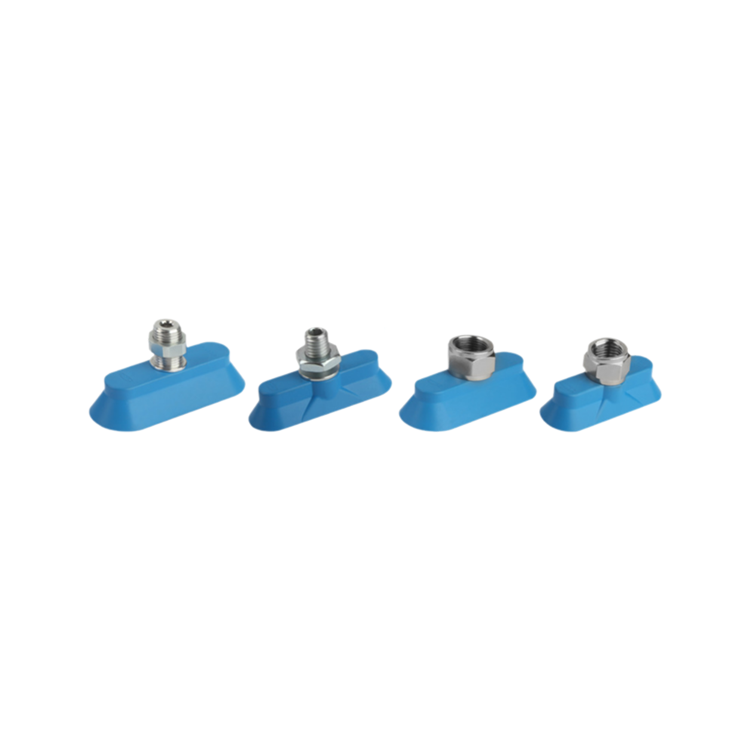

- Vitrina Produkti

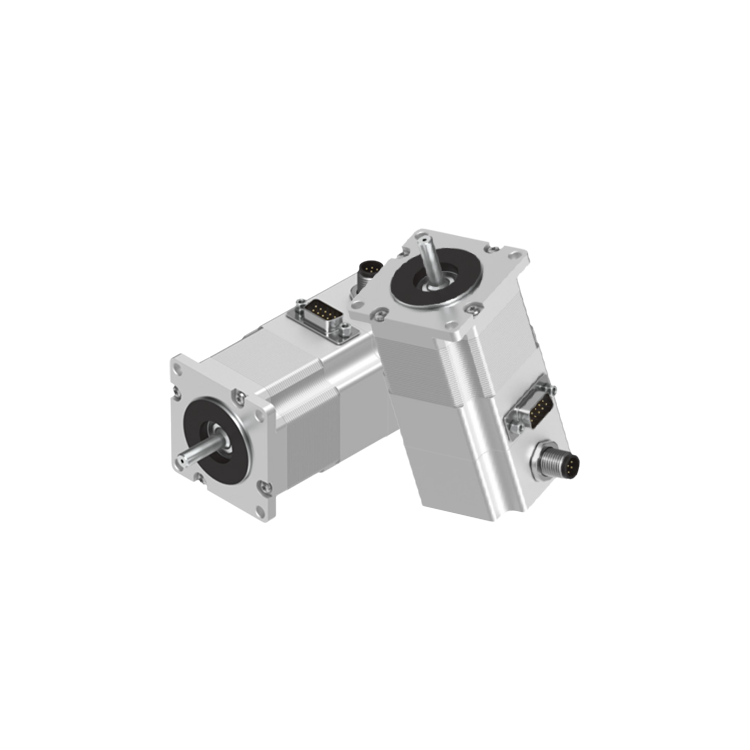

- parapamje 3D

- Përshkrimi

- Kërkesë

- Produkte të Lidhura

SOVE

Klampa e amortizimit të fiksës së robotit bazohet në një strukturë kompakte me shumë fazash për shpërndarjen e energjisë dhe ka performansë të amortizimit të përparuar në fushën e ekzekutimit në fund të robotit industrial. Projektimi i saj me vajtëz adaptiv ofronë jo vetëm mundësinë e amortizimit të goditjeve në nivel milisekondash, por përdoret specifikisht edhe për ngarkimin dhe shkarkimin e robotëve presues, montimin e përbërësve elektronikë të saktësisë së lartë dhe sistemet e manipulimit të pllakave të qelqit, duke siguruar një saktësi pozicionimi të përsëritur prej ±0,5 mm në fund, madje edhe kur ka goditje emergjence me nxitim 2G.

Si një platformë dinamike me shumë procese, është thellësisht e integruar në sistemën e amortizimit të shpejtë të ndryshimit të matricës së prodhimit të stampave (koha e ndryshimit të matricës <6 sekonda | zvogëlimi i goditjeve >90%), sistemin e shpërndarjes së energjisë kinetike të mekanizmit të nxjerrësit të formimit me injektim (forcë maksimale goditjeje <5 kN | koha e reagimit <15 ms) dhe mekanizmin e supresionit të vibracioneve të matricës së pajisjeve për derdhje në kastë (amplituda <3 μm | zhvendosja e frekuencës rezonante >30%), për të arritur menaxhim të saktë të energjisë në skenarë industriale me dinamikë të lartë.

1. Rreth modelave 3D dhe parametrave teknikë:

"Nëse ju nevojiten të riçoni, ju lutem na kontaktoni me email."

2. Rreth konsultimeve të çmimit:

"Nëse ju lutemi të merrni, ju lutem na kontaktoni. Do ta ofrojme planin më përshtatshëm për cotizim."

Përshkrimi

- Rregullim me shumë nivele të bufferit.

- Projektim vetë-rinovues.

- AR=Rezistencë ndaj Largimit

- CR=Resistencja Kimike

- OR=Oil Resistance