כפפות פנאומטיות משתמשות באוויר דחוס כדי לספק כוח מדויק למשימות תעשיתיות. לפי סיווג תפקודי, הכפפות הפנאומטיות כוללות בעיקר סוגים של **אחזקה**, **גזירה** ו**כיפוף**. הן בשימוש נרחב, ומכסות שבעה ענפי תעשייה מרכזיים:

## ⚙️ **1. ייצור ושיפוץ רכב**

**כלי עבודה מרכזיים**:

- כפפות אחזקה פנאומטיות (תיקון לוחות גוף)

- כפפות כיפוף (קצות צינורות/חוטים)

- כפפות גזירה (חוטים/קשרי חוטים)

**יישום**: כיפוף על קו ייצור מנועים, ניוד במתקני רobotics ותהליך ייצור של חבילות חוטים. *טיפ מקצועי: *כלי עבודה פנאומטיים יכולים להפחית את זמן ההרכבה ב-40% לעומת כלים ידניים במכבסות רכב.

## ? **2. חשמל ואלקטרוניקה**

**כלי עבודה מרכזיים**

- צבת מיקרו-לחיצה (מחברים/פינים למעגל מודפס)

- מקלות גזירה מדויקת (מוליכי רכיבים/חוטים)

**יישום**: סיום של פסי מעגלים בסמרטפונים, איסוי של מנועים מיקרו ועיבוד רכיבים SMT. *גורם 메incy: * מודלים אנטיסטטיים מונעים מהאלקטרוסטטיקה לפגוע ברכיבים רגישים.

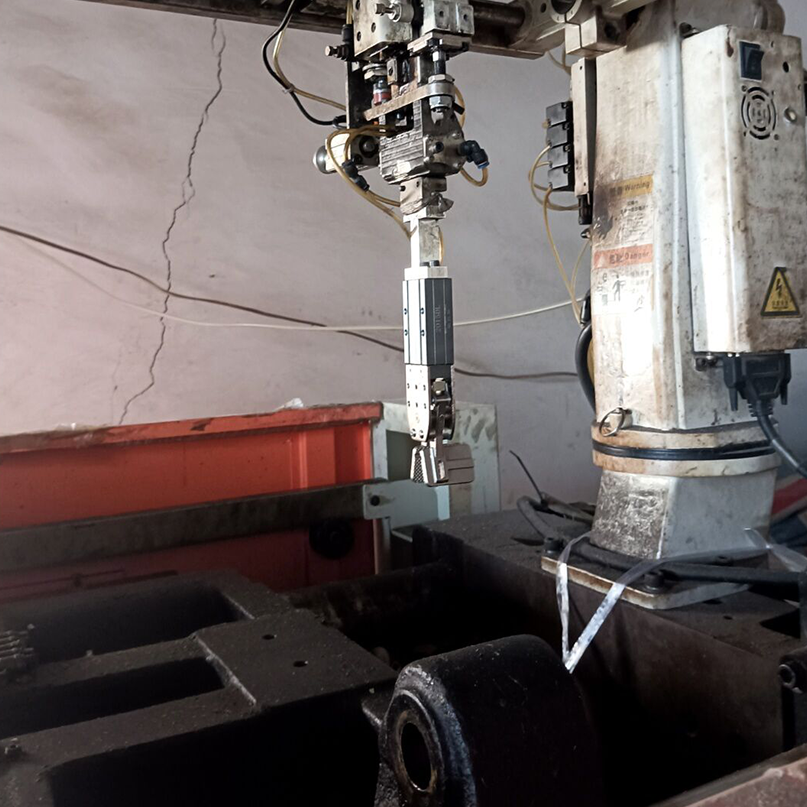

## ? **3. עיבוד מתכות**

**כלי עבודה מרכזיים**:

- גזירת בטון (מוטות בטון)

- מקלות לפליז (קיפול/חיצוי)

- אביזרי צימוד כבדים (איחוי מבני)

**יישומים**: ייצור טרסות פלדה, אמצעי אחיזה בעיבוד CNC, ושינויים במערכות צינורות. *יתרון עוצמה:* מערכת של 8-15 ליברה מטפלת באלloys בעלי חוזק גבוה שאי אפשר לработать עם כלים ידניים.

## ?️ **4. בנייה ותשתית (MEP)**

**כלים מרכזיים:**

- גזם צינורות (צינור/נחושת)

- מתקין תופס (חיזוקי מיזוג אוורור)

**יישומים** התקנת מערכת טפטוף, גזיז של בטון מזוין, וחיבורי מכניקה. *טיפ לבטחה:* חיבור לפי שיטת נעילה-ותוית הוא קריטי באתרי בנייה.

## ? **5. אריזה ולוגיסטיקה**

**כלים מרכזיים:**

- מתיח רצועה (רצועות PP/PET)

- אוגר ריקון (מאריזות)

**יישומים:** סיבוב פלטפורמות, מיון מנותח אוטומטי במתקני אחסון, וטעינה של מכולות. *נתון על יעילות:* מערכות דחוסות אוויר אוטומטיות מסוגלות לעבד מעל 300 חבילות בשעה, בעוד מערכות ידניות עיבדו עד 60 חבילות בשעה.

## ? **6. תעשיית רפואה**

**כלים מרכזיים:**

- פינצט כירורגיות סטריליות (שליטה על רקמה/сосלי)

- מיקרוטיוב קריימפרים (assy קתטרים)

**יישומים:** כירורגיה זעיר-פולשנית, ייצור ציוד לבתי-חולים, ותעשיית התקנים הניתנים להשתלה. *תאימות:* לשימוש רפואי נדרש דגם המאושר על פי תקן ISO 13485.

## ✈️ **7. תעשיות מומחות**

- **אווירונאוטיקה**: קריימפינג של סורגי טיטניום

- **תעשיית הبناء הימי**: איזום של לוחות סיפון

- **מחזור**: עיבוד פליז

---

## ? **מדוע לבחור ג'וינטס פנאומטיים? **

- **יעיל באנרגיה**: מייצר כוח 2-10 פעמים חזק יותר מקליידים חשמליים

- **ללא סיכון להתפוצצות**: בטוח לשימוש בסביבות דליקות

- **פעולה רציפה**: המנוע אינו מתחמם

- **קלות: 30% קל יותר ממכשירים עם סוללות

*תובנה תעשייתית*: בהנחיית הצורך באוטומציה בתעשיית הייצור, שוק הכלים הנאומטיים העולמי צפוי להגיע ל- ** 23 מיליארד דולר אמריקאי ** עד 2028 (CAGR 6.2%).