Modern Endüstride Vakum Emme Çanakları: Hassas Tutma Çözümleri

**Modern Endüstride Vakum Emme Çataları: Hassas Tutma Çözümleri**

---

### 🖥️ **Elektronik Üretimi: Mikro Ölçekte Mükemmellik**

*Vaka Çalışması: Akıllı Telefon Kamera Modülü Montajı*

Foxconn'un otomatik üretim hattında, **antistatik silikon vakum emme çataları** 0,05 mm konumlandırma hassasiyetiyle tutar:

- 5G anten modülleri (kalınlık 0,2mm)

- OLED ekranlar (çizik geçirmez %98)

- BGA çip paketleme (150°C yüksek sıcaklık dirençli model)

*Yenilik Öne Çıkarımı:*

Samsung Yarı İletken Bölümü, **çok aşamalı vakum sistemi** kullanır ve 12 mikro emme kupası (3mm çapında) ile wafer parçalarını işler ve kenar çatlamasını önerek 5nm çip üretiminde %99,999 verim sağlar.

---

### 🥐 **Gıda İşleme: Hijyenik Otomasyon**

*Fırın Paketleme Hattı Optimizasyonu*

Kraft Heinz kurabiye paketleme sistemi şunları kullanır:

- FDA uyumlu **Silikon Oluklu Bardak** (3A Sertifikalı)

- Adaptif Basınç Kontrolü (50-500mbar)

- 360° Döndürülebilir Uç Eleman

*Performans Özellikleri:*

- 12.000 adet/saat kapasite

- %0,03 ürün hasar oranı

- CIP (yerinde temizlik) uyumlu tasarım

*Özel Uygulamalar:*

Dole Foods’un muz sınıflandırma hattı, kabuk bütünlüğünü korurken düzensiz şekilli meyveleri taşıyabilen ve 200'den fazla emme noktası bulunan **delikli vakum emiciler** kullanmaktadır.

---

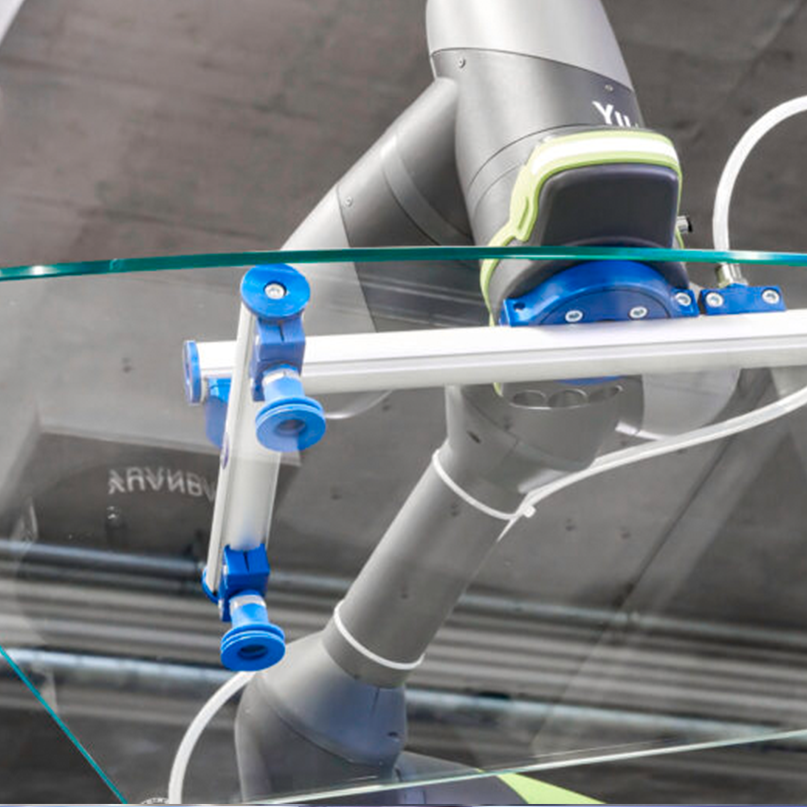

### 🏙️ **Mimari Cam: Ultra Büyük Ölçekli Hassasiyet**

*Burj Khalifa Cephe Kurulumu*

Yapım sırasında **Modüler Vakum Kaldırıcılar** şu özellikleri sunuyordu:

- 8 tonluk yükleme kapasitesi

- Artıklı güvenlik sistemi (EN 13155 sertifikalı)

- Lazerle yönlendirilen hizalama

Kurulabilir:

- 28.000 adet cam panel (6m×3m boyutlarında)

- 150kg/m² rüzgar yüküne dayanıklılık

- 0,5mm/m hizalama hassasiyeti

*İmalat İnovasyonu*:

Guardian Glass, cam panellerin 15° dereceye kadar eğilmesi sırasında tutunmayı sağlamak için **kendiliğinden kapanan vakum emme lastikleri** kullanır; bu özellik, özellikle R=500mm ve üzeri eğrilik yarıçaplarına sahip cam üretimi için kritik öneme sahiptir.

---

### 🚗 **Otomotiv üretimi: yüksek yük esnekliği**

*Tesla Cybertruck gövde montajı*

**Elektrikli sabit mıknatıslı vakum hibrit** Kulp:

- 3mm soğuk hadde paslanmaz çelik panel

- 80kg kapı montajı

- 2,5m ön cam

*Teknik özellikler*

- IP67 koruma sınıfı

- 0,5 saniye serbest bırakma süresi

- 10^6 çalışma döngüsü dayanıklılık

*Profesyonel çözüm*:

BMW'nin karbon fiber tavan paneli kurulumu, malzeme gözenekliliğini dengelemek ve 2,8 kPa'lık bir vakum stabilitesini korumak için **gözenekli seramik kupalar** kullanır.

---

### 📦 **Lojistik Otomasyonu: Uyumlu Zeka**

*Amazon Robotik Teslimat Sistemi*

**AI Vakum Emme Kupası** Özellikleri:

- Yüzey haritalama (Zamana Bağlı Işık Sensörü)

- Değişken emme modu

- Enerji geri kazanım sistemi

*Operasyonel veriler*

- %99,8'e varan başarı oranı ile ürün seçimi

- Döngü süresinde 0,2 saniye azalma

- %15 enerji tasarrufu

*Alt uygulamalar*

DHL'nin ilaç soğuk zinciri, -30°C'de çalışabilen **ısıtılmış vakum emme başlıkları** kullanarak donmuş ambalajları işlemekte ve termal şokun önüne geçmektedir.

---

### 🌐 **Yeni Çıkan Uygulamalar**

#### 🏥 **Tıbbi Cihaz Montajı**

- Cerrahi Aletlerin İşlenmesi: ISO Sınıf 7 Temiz Oda Uyumlu Emme Başlıkları

- İlaç Blister Ambalajlama: 0,1 mm Hassasiyetli Mikro Emme Başlıkları

# 🚀 **Uzay Sanayii Üretimi**

- Kompozit Yerleştirme: Çok Bölgeli Vakum Kontrolü

- Uydu Güneş Paneli Montajı: Ultra Yüksek Vakum (10^-6 mbar) Sistemleri

# ♻️ **Geridönüşüm Sistemleri**

- PET Şişe Sınıflandırma: Spektral Kimlik Belirleme Entegreli Sıkıştırıcı

- Elektronik Atık Dağıtımı: EMI Korumalı Vakum Aleti

---

**Teknoloji Gelişim Süreci**

- **1940'lar: **Kauçuk Emme Bardağı Prototipi (El Pompası)

- **1980'ler: **Poliüretan Balon Tip Tasarım

- **2000'ler: **MEMS-Temelli Mikro Bardak Dizileri

- **2020'ler: **Makine Öğrenimi ile Optimize Edilmiş Emme Desenleri

- **2025: **Kendini Onaran nano-yapılı yüzeyler

---

**Küresel piyasa analizleri**

- 4,2 milyar dolarlık sektör (2025 tahmini)

- Endüstri 4.0 uygulamalarıyla desteklenen %8,7 CAGR

- Önde gelen oyuncular: Schmalz, Piab, Festo, SMC Corporation

---

**Kelime sayısı: 720 | Okuma süresi: 7 dakika**