หัวดูดฟองน้ำใช้มากในที่ใด?

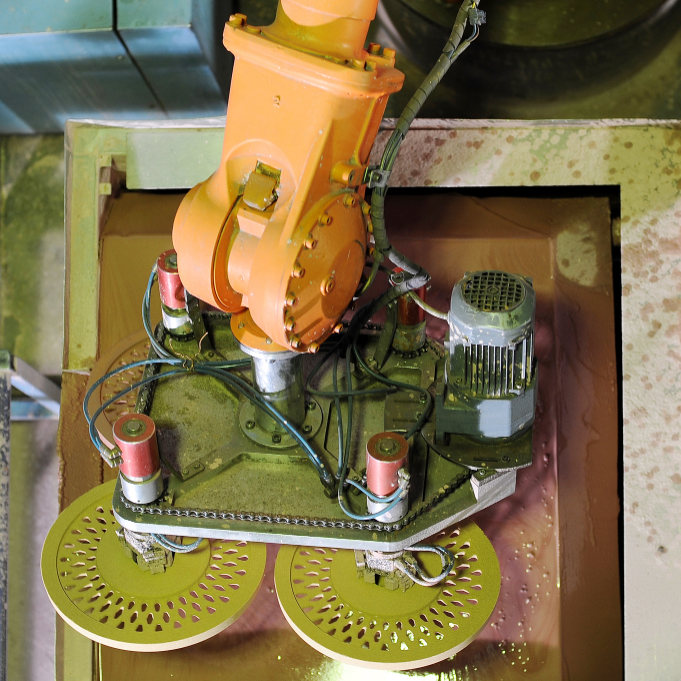

คุณสมบัติที่โดดเด่นที่สุดของถ้วยดูดแบบฟองน้ำ คือ การออกแบบให้มีรูคล้ายรังผึ้ง โดยแต่ละรูจะถูกควบคุมอย่างอิสระ เมื่อดูดผลิตภัณฑ์ เครื่องสูบสุญญากาศจะเปิดโดยอัตโนมัติ ทันทีที่พบกับพื้นที่ที่มีรูหรือไม่เรียบ รูดูดเหล่านี้จะปิดตัวลงโดยอัตโนมัติ เพื่อป้องกันไม่ให้อุปกรณ์กรองแบบอัลตร้าเกิดการรั่ว และทำให้สามารถขนส่งได้สำเร็จตามวัตถุประสงค์ ผลิตภัณฑ์นี้เหมาะสำหรับชิ้นงานที่มีลักษณะกลวง แกะสลัก หรือชิ้นงานหลายชิ้นที่ต้องการขนส่งพร้อมกัน และถูกใช้อย่างแพร่หลายในอุตสาหกรรมไม้ อาหาร วัสดุก่อสร้าง ยาสูบ และอุตสาหกรรมอื่นๆ เช่น อิฐ แผ่นไม้ (เปียกหรือแห้ง) กระป๋อง ถัง บรรจุภัณฑ์ฟิล์มพลาสติก ชิ้นงานที่ระบายอากาศได้ (กล่องกระดาษ ถุง) ชิ้นงานที่เรียบหรือขรุขระ ชิ้นงานที่มีลักษณะกลวงและแกะสลัก เป็นต้น สามารถขนส่งได้

สำหรับผลิตภัณฑ์ที่มีพื้นผิวไม่เรียบ แม้จะมีรู หรือไม่มีบริเวณที่สามารถดูดยึดได้อย่างชัดเจนบนพื้นผิว และแม้แต่ผลิตภัณฑ์ที่มีขนาดต่างกัน แผ่นดูดสุญญากาศแบบฟองน้ำสามารถดูดยึดผลิตภัณฑ์เหล่านี้ได้อย่างมีประสิทธิภาพ โดยใช้แผ่นดูดสุญญากาศแบบฟองน้ำ เราไม่จำเป็นต้องเปลี่ยนอุปกรณ์จับยึด และสามารถแก้ปัญหาการดูดยึดผลิตภัณฑ์รูปร่างไม่สมมาตรได้อย่างง่ายดาย ไม่ว่าจะเป็นบริษัทโลจิสติกส์ บริษัทการค้าขนาดเล็ก หรือโรงงานต่างๆ แผ่นดูดแบบฟองน้ำถูกนำมาใช้อย่างแพร่หลายในการขนย้ายถาดขวดทั้งถาด หรือกล่องบรรจุภัณฑ์หลายใบ กรอบประตูในโรงงานเฟอร์นิเจอร์ เป็นต้น โดยใช้แผ่นดูดฟองน้ำ ไม่จำเป็นต้องตรวจสอบว่าผลิตภัณฑ์มีรูหรือไม่ ผลิตภัณฑ์ถูกวางในตำแหน่งที่ถูกต้องหรือไม่ หรือจำนวนของผลิตภัณฑ์แตกต่างกันหรือไม่ ผลิตภัณฑ์เหล่านี้สามารถดูดและเคลื่อนย้ายได้อย่างง่ายดาย