เปิดตัวแผ่นวงจร PCB ที่ติดตั้งถ้วยดูดสุญญากาศแบบบูรณาการ: กำหนดมาตรฐานใหม่แห่งความแม่นยำในการจัดการ PCB แบบความหนาแน่นสูง

Time: 2025-08-22

บริษัท ซูโจว ชัวเว่ย ออโตเมชั่น เทคโนโลยี จำกัด เปิดตัวแผ่นวงจรพีซีบี (PCB Circuit Board) พร้อมชุดดูดสูญญากาศแบบบูรณาการ: การกำหนดนิยามใหม่สำหรับความแม่นยำในการจัดการพีซีบีความหนาแน่นสูง

อินทผลัม : 22 ตุลาคม 2025

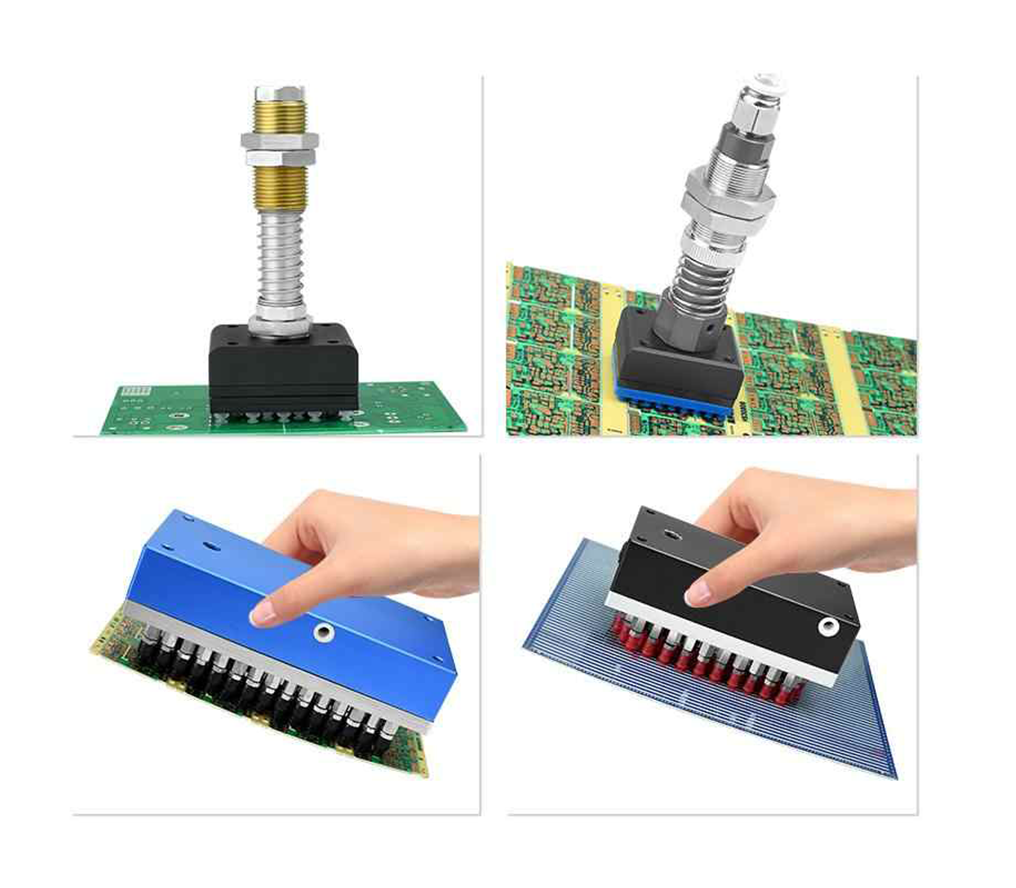

ที่ตั้ง : Suzhou Shuowei Automation Technology Co., Ltd. , ผู้นำด้านโซลูชันการจัดการระบบอัตโนมัติในอุตสาหกรรม เปิดเผยอย่างเป็นทางการถึงการวางจำหน่ายทั่วโลกของ แผ่นวงจรพีซีบี (PCB Circuit Board) พร้อมชุดดูดสูญญากาศแบบบูรณาการ — เป็นเครื่องมือที่ออกแบบมาเพื่อแก้ไขปัญหาที่เกิดขึ้นบ่อยที่สุดในกระบวนการผลิตพีซีบี ตั้งแต่ปัญหาการรั่วของสูญญากาศบนแผ่นพีซีบีที่มีรูพรุน ไปจนถึงปัญหารอยขีดข่วนบนพื้นผิวของแผงวงจรแบบยืดหยุ่น (flex circuits)

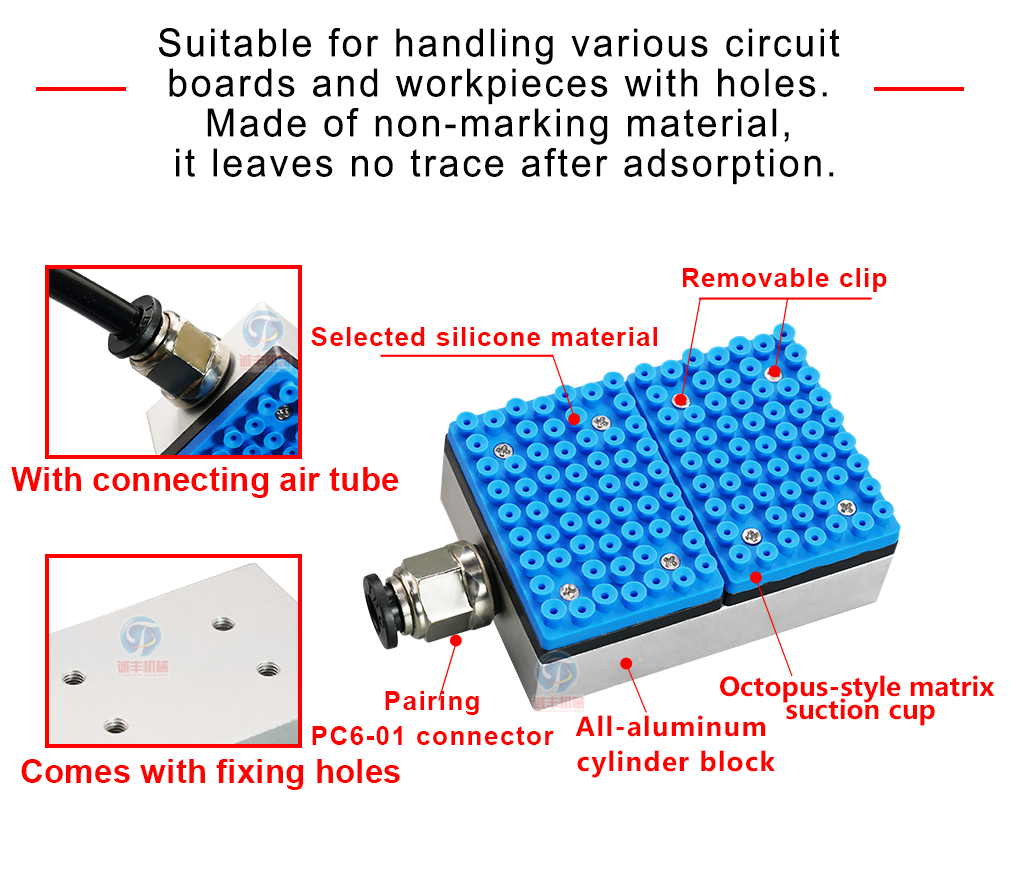

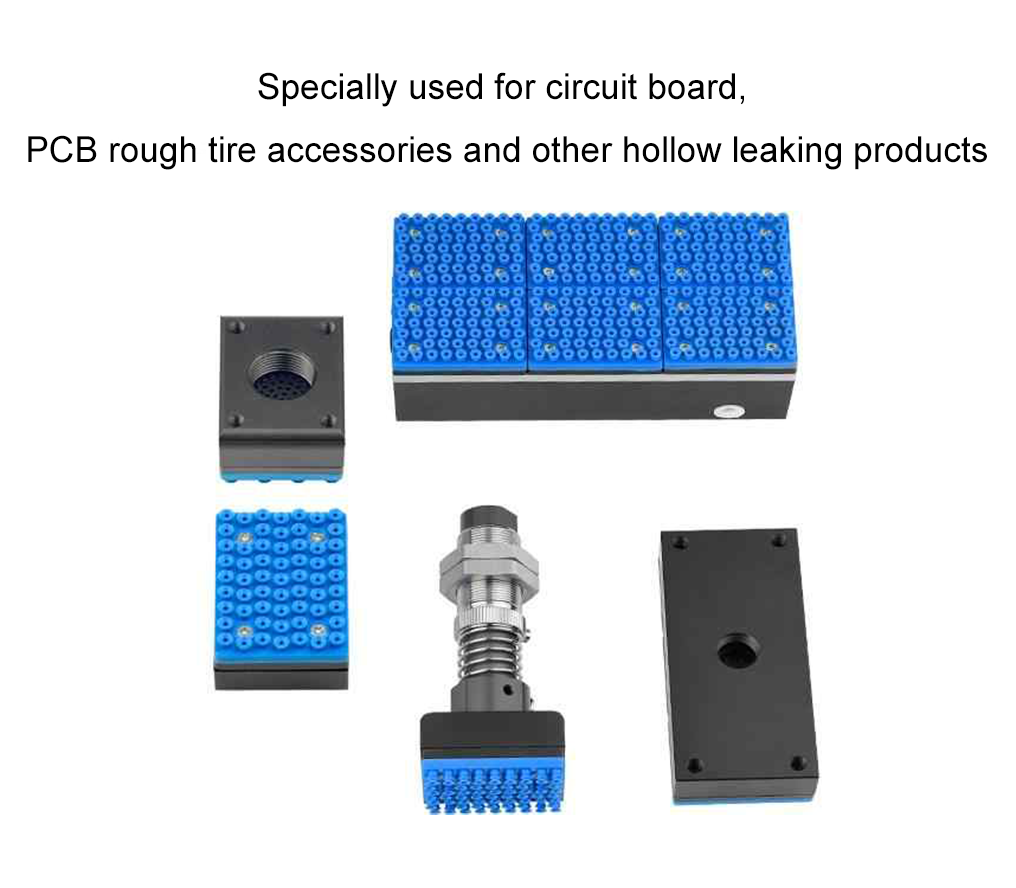

ถูกออกแบบมาเพื่อผู้ผลิตแผ่นวงจรแบบความหนาแน่นสูง (HDI) แผ่นวงจรยานยนต์ และชิ้นส่วนอิเล็กทรอนิกส์สำหรับผู้บริโภค ชุดดูดแบบบูรณาการใหม่นี้มีคุณสมบัติที่เป็นนวัตกรรมครั้งแรกในอุตสาหกรรมถึงห้าประการ รวมอยู่ในเครื่องเดียวที่ประหยัดพื้นที่: วาล์วควบคุมแบบรูพรุนเฉพาะสำหรับ PCB, รูปแบบการจัดวางถ้วยดูดแบบแมทริกซ์ที่ปรับตัวได้, กระบอกสูบทำจากโลหะผสมอลูมิเนียมน้ำหนักเบา, ถ้วยดูดซิลิโคนที่ปลอดภัยสำหรับอาหาร, และการบูรณาการระบบสุญญากาศแบบครบวงจร การทดสอบในขั้นแรกกับผู้ผลิต PCB ชั้นนำพบว่าอัตราของเสียลดลงสูงสุดถึง 92% และความเร็วในการผลิตเพิ่มขึ้น 25%

แก้ไขจุดปัญหาในการจัดการ PCB ที่ถือว่า "แก้ไม่ได้"

การผลิตแผงวงจรพีซีบี (PCB) มีปัญหาในการจัดการชิ้นงานมานานแล้ว ซึ่งเครื่องดูดแบบสุญญากาศทั่วไปไม่สามารถแก้ไขได้ แผงวงจรความหนาแน่นสูงที่มีวายอาณา (thermal vias) ขนาดเล็ก (0.1-0.3 มม.) มีการรั่วของอากาศ ทำให้ชิ้นงานตกหล่น; แผงพีซีบีแบบบาง (0.1-0.3 มม.) มีรอยขีดข่วนจากถ้วยยางที่มีความแข็ง; และการเปลี่ยนขนาดบ่อยครั้งจำเป็นต้องมีการหยุดเดินเครื่องเพื่อปรับตั้งเครื่องจับใหม่ ส่งผลให้เกิดค่าใช้จ่ายสูง รายงานอุตสาหกรรมปี 2024 พบว่า ความท้าทายเหล่านี้ทำให้ผู้ผลิตพีซีบีทั่วโลกต้องสูญเสียเงินมากกว่า 2.3 พันล้านดอลลาร์สหรัฐต่อปีจากของเสียและผลผลิตที่ลดลง

“เป็นเวลาหลายปีมาแล้วที่ลูกค้าของเราบอกกับเราว่า เครื่องจับแบบเดิมถูกออกแบบมาเพื่อชิ้นงานทั่วไป ไม่ใช่เพื่อความแม่นยำที่พีซีบีต้องการ” คุณ[ซาร่าห์ หลิว] ผู้อำนวยการฝ่ายพัฒนาผลิตภัณฑ์ของ ซูโจว บริษัท Shuowei Automation Technology Co., Ltd .เครื่องดูดแบบบูรณาการของเราไม่ใช่แค่การอัปเกรดเพียงอย่างเดียว แต่เป็นการออกแบบใหม่ทั้งหมดว่าพีซีบีควรได้รับการจัดการอย่างไร โดยทุกฟีเจอร์ถูกสร้างขึ้นเพื่อแก้ไขจุดบกพร่องเฉพาะของโซลูชันที่มีอยู่เดิม”

นวัตกรรมหลัก: เหตุใดเครื่องดูดแบบบูรณาการจึงแตกต่าง

1. วาล์วตรวจสอบแบบรูพรุน: หมดปัญหาการรั่วของอากาศบนแผง HDI

ต่างจากการใช้เครื่องดูดแบบเดิมที่ใช้ห้องสุญญากาศเพียงห้องเดียว (ซึ่งจะล้มเหลวเมื่อใช้กับแผ่น PCB ที่มีรูพรุน) โซลูชันใหม่นี้ประกอบด้วย วาล์วตรวจสอบแบบมีรูพรุนในตัว สำหรับแต่ละถ้วยในแมทริกซ์ เมื่อถ้วยใดถ้วยหนึ่งปิดทับรูหรือช่องทางไวอา (via) วาล์วของถ้วยนั้นจะปิดผนึกทันที ช่วยป้องกันการรั่วของอากาศทั่วทั้งอุปกรณ์โดยไม่ต้องปรับตั้งค่าด้วยตนเอง

สำหรับผู้ผลิตแผงวงจร PCB สำหรับอุปกรณ์ทางการแพทย์ที่นำผลิตภัณฑ์นี้ไปทดสอบใช้งาน คุณสมบัตินี้ช่วยลดของเสียที่เกิดจากการรั่วของอากาศจาก 9% เหลือเพียง 1.2% ภายในสองสัปดาห์ ซึ่งเทียบเท่ากับประหยัดค่าวัสดุได้ถึง 36,000 ดอลลาร์สหรัฐต่อเดือน "เราเคยลองใช้เครื่องดูดอื่นมาแล้วสามแบบสำหรับแผง HDI ของเรา แต่เครื่องเหล่านั้นกลับทำให้ชิ้นงานหลุดหรือทำให้วงจรบิดงอ" [ไมค์ แทน] หัวหน้าฝ่ายผลิตของบริษัททางการแพทย์กล่าว "นี่เป็นครั้งแรกที่เราสามารถจัดการไวอาโดยไม่ต้องเพิ่มแรงดัน"

2. ถ้วยดูดซิลิโคน: การจัดการพื้นผิวอย่างระมัดระวังเพื่อป้องกันรอยขีดข่วน

เพื่อกำจัดความเสียหายทางรูปลักษณ์ ซึ่งเป็นหนึ่งในสาเหตุหลักที่ทำให้ PCB ถูกปฏิเสธ ถ้วยดูดจึงทำมาจาก ซิลิโคนเกรดอาหารที่นุ่มเป็นพิเศษ (ความแข็ง Shore A 30) ต่างจากถ้วยยางที่จะแข็งตัวตามกาลเวลาและทำให้เกิดรอยขีดข่วนบนมาสก์บัดกรีหรือลายวงจร วัสดุซิลิโคนสามารถปรับเข้ากับพื้นผิวแผงวงจรที่ไม่เรียบได้ ทนต่อฟลักซ์และสารทำความสะอาด รวมถึงสามารถทนอุณหภูมิได้สูงถึง 180°C (ซึ่งสำคัญมากสำหรับการจัดการหลังเตาอบรีฟโลว์)

ลูกค้าอุปกรณ์อิเล็กทรอนิกส์ผู้บริโภคที่ผลิตสมาธ์วอช PCB เห็นอัตราการใช้งานของเครื่องสําอางตกจาก 7% เป็น 0.8% หลังจากเปลี่ยนไปใช้ถ้วยซิลิโคน รอยทองแดงที่ถูกขีดข่วนเคยหมายถึงการคัดแยกผ่านแผ่นหลายร้อยแผ่นต่อวัน กล่าวว่า [Lisa Wong] ผู้จัดการคุณภาพในบริษัท ตอนนี้เรามักจะไม่เห็นส่วนหนึ่งที่ติดป้าย

3. การจัดวางถ้วยในรูปแบบเมทริกซ์: เปลี่ยนแปลงได้อย่างรวดเร็วสำหรับแผงขนาดต่างๆ

สายการผลิต PCB มักเปลี่ยนขนาดแผงบ่อยครั้ง—ตั้งแต่แผงฟเล็กซ์ขนาด 50x50 มม. ไปจนถึงแผงแข็งขนาด 200x300 มม.—แต่เครื่องจับยึดแบบดั้งเดิมต้องใช้เวลาปรับตั้งค่าด้วยมือ 2-3 นาทีต่อการเปลี่ยนแปลงแต่ละครั้ง ด้วยหัวจับแบบดูดลมที่ติดตั้งไว้ล่วงหน้า เมทริกซ์แบบ 4x6 ที่ปรับตั้งถ้วยได้ (เส้นผ่านศูนย์กลาง 12 มม. ต่อชิ้น) ช่วยกำจัดการหยุดทำงานนี้: แก้วดูดล็อกเข้าที่ได้ทันทีภายใน 10 วินาทีผ่านฐานแม่เหล็ก ครอบคลุมขนาด PCB ทั่วไปทั้งหมดโดยไม่ต้องใช้เครื่องมือ

ผู้ผลิตตามสัญญาที่ดำเนินการผลิต PCB 8 ขนาดแตกต่างกันในแต่ละวัน สามารถลดเวลาในการเปลี่ยนเครื่องจักรลงได้ถึง 95% — จากเดิม 24 นาที เหลือเพียง 1.2 นาทีต่อวัน "เราเคยต้องจัดพนักงานสองคนให้มาปรับตั้ง Grip อยู่ตลอดเวลา" [เดวิด พาร์ค] ผู้จัดการฝ่ายปฏิบัติการกล่าว "ตอนนี้พนักงานเพียงหนึ่งคนก็สามารถควบคุมไลน์การผลิตทั้งหมดได้แล้ว

4. กระบอกสูบอะลูมิเนียมอัลลอยด์: ดีไซน์ประหยัดพื้นที่สำหรับไลน์แคบ

Gripper แบบดั้งเดิมที่มีขนาดใหญ่ — ประกอบด้วยปั๊ม วาล์ว และโครงเหล็กแยกกัน — มักบังคับให้ผู้ผลิตต้องออกแบบไลน์อัตโนมัติใหม่ให้เข้ากับอุปกรณ์ ขณะที่แกนหลักของถ้วยดูดแบบใหม่นี้คือ กระบอกสูบอะลูมิเนียมอัลลอยด์ 6061-T6 ซึ่งช่วยลดน้ำหนักลง 40% (1.2 กก. เทียบกับ 2 กก. สำหรับหน่วยขนาด 200x300 มม.) และยังรวมท่อสุญญากาศไว้ภายในโครงสร้างโดยตรง

ผู้ผลิตแผงวงจรสำหรับอุตสาหกรรมยานยนต์รายหนึ่ง หลีกเลี่ยงค่าใช้จ่ายในการออกแบบไลน์การผลิตใหม่ถึง 120,000 ดอลลาร์ ด้วยการใช้หน่วยอุปกรณ์ขนาดกะทัดรัดที่สามารถติดตั้งในพื้นที่แคบได้ถึง 150 มม. "เราคิดว่าคงต้องหยุดการผลิตเป็นสัปดาห์เพื่อขยายไลน์", [เจมส์ เชน] ผู้อำนวยการฝ่ายวิศวกรรมกล่าว "ตัวจับชิ้นส่วนนี้พอดีเป๊ะ—ไม่ต้องปรับปรุงแก้ไขอะไรเลย"

5. การผสานการใช้งานแบบ All-in-One: ความเร็วสำหรับไลน์การผลิตที่มีปริมาณสูง

ไลน์การผลิตแผงวงจรเร็วสูง (30 แผง/นาทีขึ้นไป) ไม่สามารถยอมให้การสร้างแรงดูดช้าลงได้—แต่อุปกรณ์จับแบบมาตรฐานใช้เวลา 0.8-1 วินาทีในการสร้างแรงดัน ในขณะที่อุปกรณ์จับแบบผสานรวมวาล์วตรวจสอบ ท่อรวม และถ้วยดูดเข้าไว้ในหน่วยเดียว สามารถสร้างแรงดูดภายใน 0.15 วินาที ทำให้ทันไลน์การผลิตที่ผลิตได้ 45 แผง/นาที

ผู้ผลิตแผงวงจรสมาร์ทโฟนรายหนึ่งที่ใช้อุปกรณ์นี้ สามารถเพิ่มความเร็วไลน์การผลิตได้ถึง 25% จากเดิม 32 เป็น 40 แผง/นาที "แผงเพิ่มอีก 8 แผงต่อนาทีนั้น คิดเป็น 1,600 หน่วยต่อวัน", [ทอม จาง] ผู้จัดการฝ่ายการผลิตกล่าว "มันคือความแตกต่างระหว่างการบรรลุเป้าหมายและการผลิตไม่ทัน"

มีพร้อมให้บริการทั่วโลก พร้อมตัวเลือกในการปรับแต่ง

แผงวงจร PCB ที่ติดตั้งถ้วยดูดสุญญากาศแบบบูรณาการ สามารถสั่งซื้อได้แล้วทั่วโลก พร้อมด้วยโมเดลเฉพาะทาง 4 รุ่น เพื่อให้เหมาะกับความต้องการในการผลิตที่แตกต่างกัน ได้แก่

- PCB-VAC-46P : ออกแบบมาเพื่อให้เหมาะกับแผงวงจร HDI และแผงวงจรที่มีรูพรุน โดยมีวาล์วตรวจสอบรูพรุนขั้นสูง

- PCB-VAC-46S : ออกแบบมาเพื่อให้เหมาะกับแผงวงจรยืดหยุ่นและแผงวงจรบาง โดยมีถ้วยซิลิโคนและโหมดความดันต่ำ

- PCB-VAC-46M : เหมาะสำหรับการผลิตหลายขนาด พร้อมการออกแบบเรียงแบบแมทริกซ์และการล็อกถ้วยด้วยแม่เหล็ก

- PCB-VAC-46H : ออกแบบมาเพื่อให้เหมาะกับสายการผลิตความเร็วสูง โดยให้ความสำคัญกับการตอบสนองสุญญากาศที่รวดเร็ว

บริษัท Shuowei Automation Technology Co., Ltd. ยังให้บริการการปรับแต่ง, รวมถึงขนาดถ้วยที่กําหนดเองสําหรับ PCBs ที่ไม่เป็นมาตรฐานและตัวปรับความสอดคล้องสําหรับแขนหุ่นยนต์เฉพาะเจาะจง (เช่น Fanuc, ABB, KUKA).

ขั้นตอนต่อไปสําหรับผู้ผลิต

เพื่อเรียนรู้เพิ่มเติมเกี่ยวกับ PCB Circuit Board Integrated Vacuum Suction Cups ผู้ผลิตสามารถ:

- การเยี่ยมชม https://www.sove-tech.com/เพื่อดูรูปแบบ 3 มิติ และรายละเอียดเทคนิค

- ขอการทดสอบแบบทดลองฟรีในสถานที่ หรือตัวอย่าง PCB ผ่านอีเมล: [email protected]

- โทรหาทีมงานขายทั่วโลกที่ +18362520426 เพื่อแนะนําตามความต้องการ

pCBs กลายเป็นเล็กและซับซ้อนมากขึ้นทุกปีและเครื่องมือการจัดการต้องติดตาม เติม [Sarah Liu] การเปิดตัวนี้คือความมุ่งมั่นของเราในการช่วยผู้ผลิตให้เปลี่ยนการจัดการจากปวดหัวเป็นข้อดีในการแข่งขัน

เกี่ยวกับ บริษัท Shuowei Automation Technology Co., Ltd.

บริษัท Shuowei Automation Technology Co., Ltd. ออกแบบและผลิตโซลูชันระบบอัตโนมัติสำหรับการจัดการความแม่นยำสำหรับอุตสาหกรรมต่างๆ เช่น อิเล็กทรอนิกส์ ยานยนต์ อุปกรณ์ทางการแพทย์ และสินค้าอุปโภคบริโภค โดยมุ่งเน้นการแก้ปัญหาที่ลูกค้ายังไม่ได้รับการตอบสนอง ผลิตภัณฑ์ของบริษัทถูกใช้งานโดยผู้ผลิตมากกว่า 1,200 รายใน 45 ประเทศ ช่วยเพิ่มประสิทธิภาพให้วัดผลได้ชัดเจน ลดของเสีย และเพิ่มความเร็วในการผลิต