Lansohet Seria Mini Fixture: Mini Fixture të Vakumit, Klampe të Vogla Pneumatike & Gripë pneumatikë me mbështetëse silikoni

Time: 2025-08-21

Data : 22 Gusht 2025

Lokacion : Suzhou Shuowei Automation Technology Co., Ltd. , një furnizues i besuar i zgjidhjeve për kapje automatike industriale, sot ka njoftuar lansimin global të Serisë Mini Fixture - një trio mjetesh kompakte, me saktësi të lartë të dizajnuara për të zgjidhur sfidën e gjatë të manipulimit të pjesëve të vogla, të delikate ose të formave të rregullta. Linja e re e produkteve përfshin tri variante të specializuara: Mini Fixtures me vakum, Kapëse pneumatike të gjera të vogla dhe Kapëse pneumatike me mbështetëse silikoni, të përshtatura për industri që shkojnë nga prodhimi i pajisjeve elektronike deri te montimi i pajisjeve mjekësore.

Lokacion : Suzhou Shuowei Automation Technology Co., Ltd. , një furnizues i besuar i zgjidhjeve për kapje automatike industriale, sot ka njoftuar lansimin global të Serisë Mini Fixture - një trio mjetesh kompakte, me saktësi të lartë të dizajnuara për të zgjidhur sfidën e gjatë të manipulimit të pjesëve të vogla, të delikate ose të formave të rregullta. Linja e re e produkteve përfshin tri variante të specializuara: Mini Fixtures me vakum, Kapëse pneumatike të gjera të vogla dhe Kapëse pneumatike me mbështetëse silikoni, të përshtatura për industri që shkojnë nga prodhimi i pajisjeve elektronike deri te montimi i pajisjeve mjekësore.

Pika e Dhimbjes: Përpunimi i Pjesëve të Vogla Kërkon Më Shumë se Vetëm 'Fiksatura të Zvogëluara' Standarde

Fiksaturat industriale tradicionale shpesh herë nuk funksionojnë kur kërkohet të kapin pjesë të miniaturizuara (p.sh., konektore elektronike 5–20 mm, pjesë mjekësore mikro, apo fiksues plastikë të vegjël). Disa nga problemet më të shpeshta përfshijnë:

- Papërndjekshmëri : Fiksaturat e mëdha nuk arrijnë të kapin sipërfaqet e vogla, çka çon në rrëshqitje gjatë montimit apo transportit.

- Rrezik Dëmtimi : Fiksaturat metalike të forta i scratch apo i deformojnë materiale e cila janë të thyeshme si plastikat e holla apo elektronika e përfolur.

- Zgjidhshmëri e Kufizuar : Çapët e ngushta të fiksaturave nuk janë në gjendje të përshtaten në ndryshime të vogla të madhësisë në prodhimin me sasi të vogla.

“Prodhuesit në sektorët e elektronikës dhe mjekësisë po punuan gjithnjë e më shumë me komponentë më të vegjël se një gishtërinjë—por mjetet e kapjes së tyre nuk janë përditësuar për këtë,” tha [Wu Qiu Rong], Drejtor i Zhvillimit në Suzhou Shuowei Automation Technology Co., Ltd. "Seria jonë e mini fiksatorëve nuk është thjesht 'klemë standarde më të vogla'—është një zgjidhje e rivizualizuar që i jep përparësi saktësisë, mbrojtjes dhe fleksibilitetit për aplikime në shkallë mikro."

Tre Produktet Kryesore: Të Përshtatura për Nevojat e Përbërësve të Vegjël

Secili variant në Serinë e Mini Fiksatorëve i adreson pikat e veçanta të vështirësisë, duke siguruar vershtësi nëpër procese prodhimi me saktësi të lartë:

1. Mini Fiksatorë me Vakum: Marrje e Sigurt për Pjesë të Vogla

Të projektuara për pjesë edhe të vogla sa 3 mm (p.sh., çipat SMD, sensorë mikro), Mini Fiksatorët me Vakum përdorin thithje vakumi me presion të ulët (5–8 kPa) për të krijuar një mbajtje të qëndrueshme pa u mbështetur në forcën fizike të klemës. Karakteristikat kryesore përfshijnë:

- Dizajn ultra-kompakt (15mm × 10mm × 8mm) që përshtatet në hapësirat e ngushta të automatizimeve (p.sh., krahë robotikë për montim PCB).

- Rrjedhë vakumi e rregullueshme për të përputhur peshën e pjesës (mbështet përbërësit 0.1–5g).

- E përshtatshme me shumicën e sistemeve automatike për të marrë dhe vendosur (p.sh., Yamaha, Juki).

I përshtatshëm për : Prodhimi i elektronikës (vendosja e komponenteve në PCB), mikro-robotika.

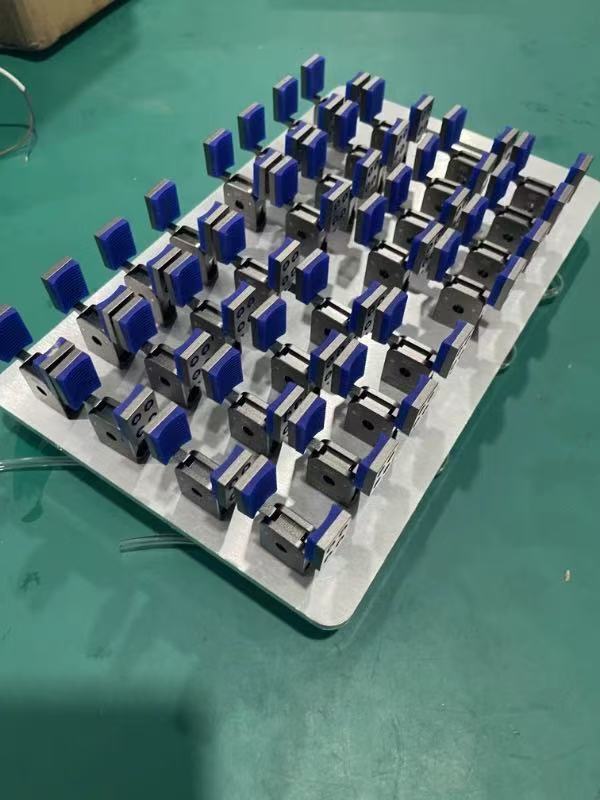

2. Mengjet e Vogla të Gjerë Pneumatike: Mandibula të Përshtatshme për Pjesë të Vogla të Rregullta

Të Mengjet e Vogla të Gjerë Pneumatike zgjidhni problemin e "mandibulës së ngushtë" me një sipërfaqe prehje 12 mm të gjerë—3x më e gjerë se mengjet e vogla standarde—dhe në të njëjtën kohë të ruani një madhësi kompakte të përgjithshme (22mm × 18mm × 10mm). Përfitimet përfshijnë:

- Veprimi pneumatik (presion ajri 0,4–0,6 MPa) për forcë të prehjes së qëndrueshme dhe të përsëritshme.

- Faqe të ndërrueshme (plastike ose metalike) për t'i përshtatur materialit të pjesës.

- Dizajn me ndërrim të shpejtë: Ndërroni mengjet brenda 30 sekondash për t'u përshtatur me ndryshimet në prodhimin serik.

I përshtatshëm për : Montimi i pjesëve plastike të vogla (p.sh., pjesë lojërash), konektore të mikroautomjeteve.

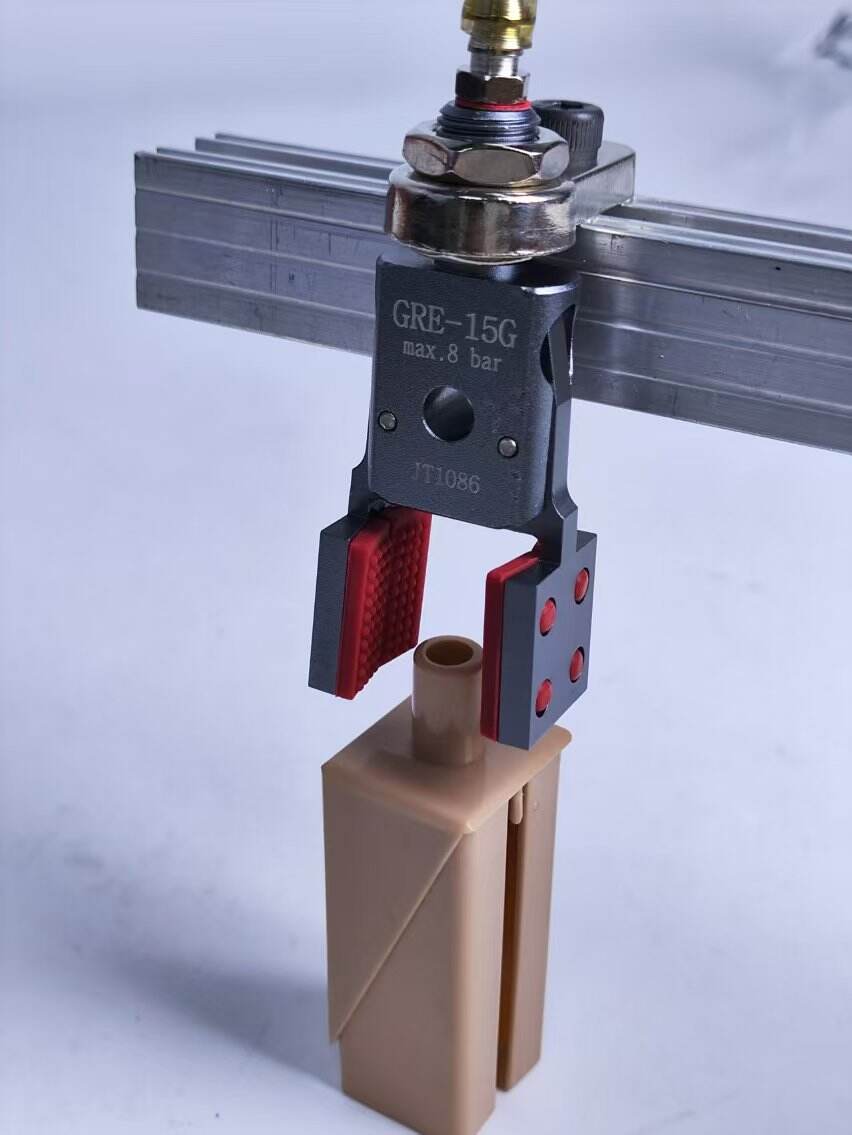

3. Mengjet Pneumatike me Jastëk Silikoni: Prehje pa Dëmtim për Pjesë të Delikate

Për pjesë të thyeshme (p.sh., pjesë optike të përfolura, tuba mjekësore me mure të holla), Pinceta Pneumatike me Këmbëza Silikoni kombinojnë mbajtjen e butë me stabilitet të fortë. Benefitët kryesore:

- Këmbëza silikoni të shkëlqyeshme, anti-shkrifte (3 mm trashësi) që përputhen me sipërfaqet e pjesëve, duke eliminuar shenjat.

- Rezistenca ndaj temperaturës (-10°C deri në 130°C) për përdorim në pasurim ose montim me temperaturë të ulët.

- Montim me dy veprime (hap/mbyll në 0.2 sekonda) për të qëndruar në kohë me linjat e shpejta.

I përshtatshëm për : Prodhimi i pajisjeve mjekësore (p.sh., përbërësit e kateterëve), montimi i pajisjeve optike.

Ndikimi në Botën Reale: Parakaluesit Raportojnë Montim 25% më të Shpejtë & 90% më Pak Dëme

Teste beta me një prodhues të madh elektronikë (që prodhon përbërës për orët e mençura) dhe një firmë pajisjesh mjekësore (që bën çip mikrofluidik) dhanë rezultate të mira:

- Shpejtësia e Montimit : 25% më të shpejtë kohë cikli, falë dizajnit të shpejtë dhe kompakt të pajisjeve.

- Zvogëlim i Dëmeve : 90% më pak pjesë të_scratchuara ose të deformuara, në krahasim me kliptet metalike standarde.

- Kohë Pushimi e Uldhur : 40% më pak kohë e shpenzuar për rirregullimin e kramponëve për variacionet e pjesëve.

"Mikrofluidikët tanë janë vetëm 10 mm të gjërë dhe kanë kanale të delikëta - kramponët standarde i shtypnin ose i largonin," tha [John Smith], Menaxher i Prodhimit në firmën e pajisjeve mjekësore. "Përzierësit me mbështetës silikoni i mbajnë të përsosur, dhe nuk kemi pasur asnjë pjesë të dëmtuar që nga kalimi."

Disponueshmëria & Hapat e Ardhshëm

Seria Mini Fixture është tashmë në dispozicion për blerje globale, me opsione personalizimi (p.sh., madhësi të veçanta për gozhë, materiale të veçanta silikoni) për klientët me sasi të mëdha. Për të mësuar më shumë:

- Vizito Faqja e internetit /mini-fixtures për të parë specifikat e produktit dhe modele 3D.

- Kërkoni një mostrë falas ose demo virtuale me email: sales [email protected]

- Thirrni grupin e shitjeve në [+18261844880] për rekomandime të personalizuara.

Rreth Suzhou Shuowei Automation Technology Co., Ltd.

Suzhou Shuowei Automation Technology Co., Ltd. projektton dhe prodhon zgjidhje industriale për kapje dhe manipulim automatik për prodhues globalë. Me një fokus në saktësi dhe inovacion të orientuar nga klienti, kompania shërben sektoreve që përfshijnë elektronikën, automjetet, pajisjet mjekësore dhe mallrat e konsumit, duke ofruar mjete që rrisin efikasitetin, zvogëlojnë shtimin dhe përshtaten me nevojat e prodhimit që ndryshojnë.