אם אתה מנהל מפעל או אופרטור זרוע רובוטית, אתה מכיר את התרחיש:

- בוקר יום שני: השקעת 40 דקות בהתקנת משאבות ואקום חיצוניות רק כדי להתחיל לסerek קרטונים - ואז צינור מטפטף באמצע המשמרת, מה שמפסיק את הייצור.

- בצהריים ביום רביעי: מוצא ערימה של לוחות עץ מקושטים שנScratches על ידי כפפות ספוג קשיחות - מקלפות 500 דולר חומרים ומעכבות הזמנה.

- ביום שישי: מבזבז שעתיים בהחלפת 3 כפפות ספוג שונות כדי להתמודד עם לוחות פליז דקים, קרטונים בינוניים ולוחות עץ רחבים - הכל לפני הצהריים.

אלה לא סתם אי נוחויות. סקר הרובוטיקה התעשייתית לשנת 2025 גילה ש אי-יעילות בכפפות הספוג גובות מהמפעלים 12-15 שעות של זמן ייצור בשבוע —זמן שאתה לא יכול להרשות לעצמך לאבד.

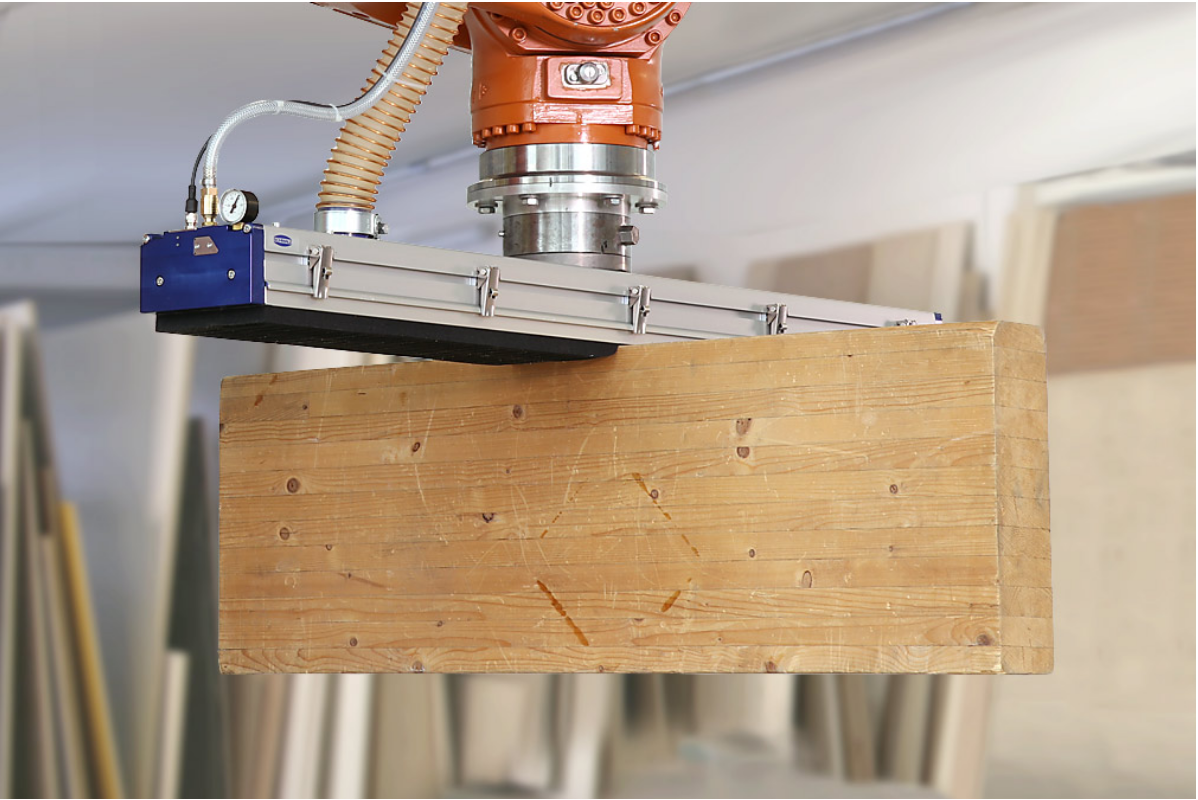

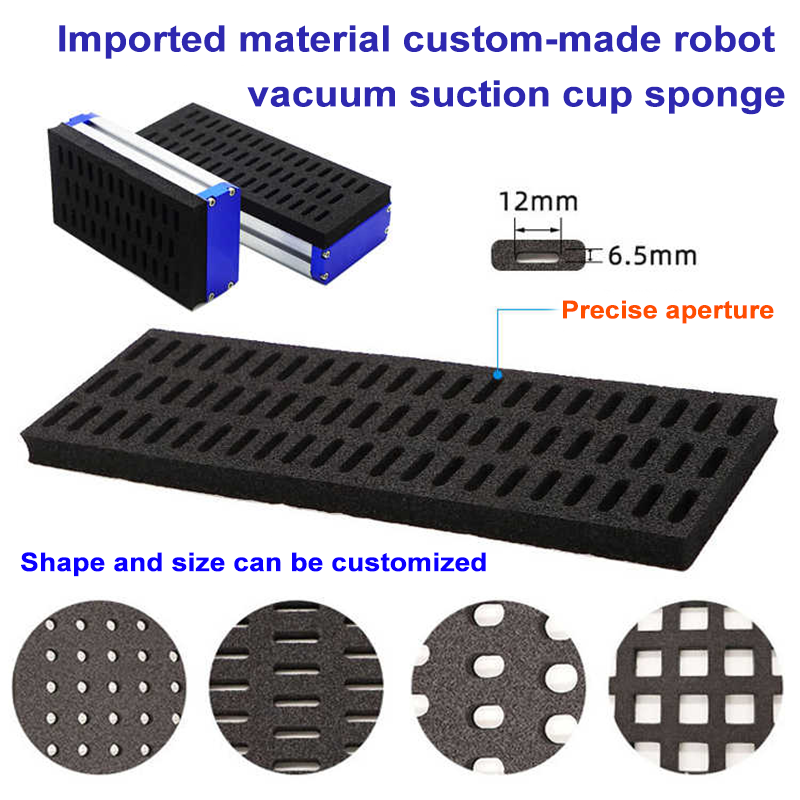

המוצר החדש שלנו Width-Integrated Vacuum Sponge Suction Cups נבנו במטרה לסיים כאבים אלו. הם פותחו כפתרון כולל (המשלב טכנולוגיית סיליקון ואקום רובוטית מובנית, מערכת ואקום לפאלה מובנית ורוחב ניתן ל réglage), והופכים את ה"הרים מפריכים" ל"פעולה חלקה וחופשית מקnishot" עבור kartons, פליז ועץ. בואו נבחן איך הם פותרים את שלוש הנקודות הקשות ביותר שאתם מתמודדים איתן.

נקודת כאב 1: מערכות אספס חיצוניות נפוחות = התקנה איטית ואספסים עם דליפה

כלי ספיגה מסורתיים לתוך רובוטים סומכים על משאבות, צינורות ומסננים נפרדים כדי לפעול. עבור מריה, מנהלת לוגיסטיקה במחסן מסחר אלקטרוני באירופה, זה אומר:

- 45 דקות של התקנה לכל זרוע רובוטית (רק כדי לחבר צינורות ולכייל לחץ) לפני שהצוות שלה יכול להתחיל לפלטט קלטות.

- 18% מההcurityות נכשלות באמצע מחזור בגלל צינורות רופפים או מסננים חסומים שמשבשים את החותם, מה שמאחר shipments של 2-3 משאיות בשבוע.

- שימוש מיותר בשטח הרצפה: משאבות חיצוניות תפסו שטח של 4x6 רגל ליד כל תחנת עבודה, ומשאירות אין מקום לאריזת קלטות נוספת.

הפתרון: מערכת אספה מובנית ל"חיבור והפעלה" מהירה

הכוסות שלנו המותאמות לרוחב הן כלים לאספה המורכבים על פלטפורמות עם מערכת אספה מובנית —אין צורך בציוד חיצוני. כך זה שינה את תהליך העבודה של מריה:

- התקנה תוך 10 דקות : להצמיד את הכוס ישירות למעוזי הרובוט של פנוק, להדליק ולתת להתחיל להרים. אין צינורות, אין קליברציה, אין המתנה.

- אספה יציבה של -92 קילו-פסקל : המערכת המובנית יוצרת אספה בתוך 0.2 שניות, ומשמרת חותם הדוק גם כאשר קופסאות מזיזות או נפוחות. תקלות הקשורות לאי-חותם ירדו מ-18% ל-0.6%.

- מסנן צונח : מסנן היגייני של 5 מיקרון שניתן לשטיפה תופס אבק מקופסאות וחומרי הדבקה, ודורש ניקוי רק פעם אחת ב-4 שבועות (לעומת פעם כל יומיים במסננים חיצוניים). צוותו של מריה מוציא כעת 85% פחות זמן על תחזוקה.

"פעם הייתה לנו טכנאית שעסקה רק בהחלפת צינורות אספה," אמרה מריה. "עכשיו זה עוד יום של תפוקה מוספת שניתן להקדישו למשלוח ההזמנות."

נקודת כאב 2: כוסות קשיחות = חפצים מקושטטים וכסף מובזבז

עבור טומאס, מנהל תפעול במתכת בגרמניה, כוסות סיליקון פלסטיות היו חלום מלחמתי מתמשך:

-

7% מפלטות פליז (בעובי 3–10 מ"מ) נקשקשו במהלך ההרמה, מה שהכריח

500 בעבודה חוזרת לכל פלטה כדי לעמוד בדרישות הלקוח.

- טבלאות עץ מבריקות ללקוח רהיטים? 10% מהן נפסלו מכיוון שכוסות קשיחות השאירו סימני עיגולים על פני השטח.

- אפילו קופסאות weren't safe: קצות חדים על הכוסות הישנות קרעו 5% מהאריזות הממותגות, מה שהכריח את צוותו לארוז מחדש את ההזמנות.

הפתרון: אחיזה משולבת של סיליקון וספוג (ללא קשקוש) בטיפול

הכוסות שלנו, המשולבות ברוחב, משתמשות ב עיצוב היברידי של סיליקון וספוג —חלש דיו כדי защира שטח רגיש, אבל חזק דיו כדי לתפס חומרים מחוספסים. כך נראה מה שראתה תומס:

- קרטונים : kết cấu ép được của الإسفنج يتكيّف مع الأسطح المتضخمة أو المموجة، ويمنع التمزق. انخفضت نسبة الفاقد من الصناديق إلى 0.3%.

- לוחות פלדה : משטח הסיליקון המורמה תופס את פלדת הסקאלה ללא השארת שריטות. עלויות העריכה ירדו ב-1,200 דולר בחודש

- לוחות עץ : שכבת הספוג הרכה פועלת כבומר, שמירה על משטחי אלון/מקר מלוכלכים ללא סימנים. פסולת עץ ירדה מ-10% ל-0.2%.

"הייתי עצרת את נשימתי בכל פעם שהרמנו עץ משובח", צחק תומאס. עכשיו אני אפילו לא חושב על זה, הכוסות עושות את העבודה בצורה מושלמת.

נקודת כאב 3: כוסות ברוחב קבוע = החלפת כלים קבועה

דמיינו זאת: אתם מתחילים את היום עם הרמת לוחות פלדה רוחבים 300 מ"מ, עוברים לקופסאות 600 מ"מ בצהריים, ומסיימים עם לוחות עץ של 1200 מ"מ. עם כוסות מסורתיות, זה אומר:

- הפסקת הייצור כל שעתיים כדי להחליף כלי עבודה (20-30 דקות לכל תחליף).

- אחסון של 3 מערכות כוסות ויותר לכל עמדת עבודה (בזבוז מקום ועלייה בעלויות).

- אימון של מפעילים חדשים להשתמש בכוסות שונות עבור עומסים שונים (הוספת 4 שעות לזמן הסנכרון).

הפתרון: עיצוב משולב ברוחב = אין צורך להחליף יותר

הכוסות שלנו פותרות את הבעיה בעזרת רוחב מתואם (300 מ"מ עד 1200 מ"מ) וקטעים של ספוג מודולריים. כך זה עובד עבור ליסה, מפעילה בפיצריה לרהיטים:

- עומסים צרים (300 מ"מ) : היא משתמשת בקטע ספוג בודד כדי להרים לוחות פליז דקים לשרשראות שולחנות.

- עומסים בינוניים (600 מ"מ) : היא מוסיפה שני קטעים כדי להטיל אריזות שטוחות של חלקי כיסאות.

- עומסים רחבים (1200 מ"מ) : משתמשת במבנה שלושת הקטעים המלא עבור שולחנות עץ גדולים.

- ללא עצירות, ללא החלפות, ללא בזבוז זמן. צוות ליסה חוסך כעת 2+ שעות ביום בהחלפת כלים.

"לפני כן, ביליתי יותר זמן בהחלפת כוסות מאשר בהרמת חומרים," אמרה ליסה. "עכשיו אני יכול להתמקד בשליחת ההזמנות מהר יותר."

מה זה אומר עבור הרווח הסופי שלך

מספרים לא משקרים. כך עוזרים יריעות האבקציה שלנו לשאר המפעלים:

- לוגיסטיקה : סורטיר קרטונים מהיר ב-35%, חיסכון של 1,700 $ בשבוע בפסולת.

- ייצור מתכות : 95% פחות פלטות פלדה מקושטות, 40% יותר פלטות מועפות לשעה.

- ייצור מебלים : 0.2% דרגת פסולת עץ, מחזור ייצור מהיר ב-18%.

מוכנים לפתור את כאבי הראש בהובלת רובוטים?

אינכם חייבים להאמין לנו על מילה—ראו בעצמכם כיצד הכוסות פועלות עם שלך רובוטים ו שלך עוסקים (קרטון, פלדה, עץ) עם הדגמה חינמית באתר. הצוות שלנו י:

- יבדוק את הכוסות על גבי זרועות הרובוט הספציפיות שלכם (Fanuc, KUKA, ABB, וכו').

- יראה לכם כיצד לכוון את הרוחב עבור העומסים הנפוצים ביותר.

- ישאיר דו"ח מותאם אישית שמראה כמה זמן וכסף תוכלו להרוויח.

"הכוסות האלה לא רק שיפרו את זרועות הרובוט שלנו – הן שיפרו את כל תהליך הייצור," אמר מנהל מפעל אחד. "הגענו למהירות רבה יותר, משליכים פחות פסול, וצוות העבודה פחות סטרס. זו הסוג של כלים שמביאים שינוי אמיתי."