Երկարավոր պնեվմատիկ սակագլուխ՝ ավտոմոբայլի գերակայության սեփական համակարգացված ստեղծագործության կենտրոնական հանգունեցուցիչը:

Գլոբալ մեքենակիցները 面料ի երկու դիրքային հարցերին՝ տարբեր մոդելների խառնավոր գործարկում (միայնուսուցիչ ≥ 8 մոդելների փոխանակում) և լայնական նյութերի պատերազմին (ալյումինիում/կարբոնային թղթերի մասաբաժնումը գերազանցում է 35%-ը): Ավարտական մեխանիկական սահմանափակումները կարող են արդյունավետորեն հեռացվել ստիเฟնական կոնտակտի վրայով (տարեկան կորցնում $2.6 միլիարդ) և ժամանակատար մոդելի փոխանակումով (միջին 45 րոպե/անգամ): Վակումներային պնեվմատիկ սացկառակ ստացել են գերակշռությունը առանձնացնող հայտարարություն + զրո ճնշումով կոնտակտ - մեքենական ավտոմատացումի աշխարհային ตลาดը կհասնի $134 միլիարդ 2025-ին (McKinsey-ի նախատelling), և վակուումի տեխնոլոգիայի մասնակցությունը կգերազանցի 50%-ը:

Դեպի արտադրություն: բարձր ճշգրտությամբ թղթի սահմանում

Industry pain points:

0.7մմ գերասեր արկանի թղթերի ձեռնարկման դեպքում կոճանակների մակարդակը >12%, իսկ լազերային միացված թղթերի դիրքային սխալը կազմում է ±1.5մմ:

Լուծում՝

Միկրոպորային արագացումի խումբ՝ ավտոմատացումով կարգավորում է արագացման ուժը թղթի ձևափոխության համաձայն (200+ անկախ վակուումի տարածք):

Մագնիսական օգնությամբ դիրքավորում՝ ալյումինիում հավաքածախաղացի սեփակցությունը հասնում է ±0.2մմ (իրական չափում է Tesla Berlin գործարանում):

Ասիական արդյունավետության դիզայն՝

▶ დüşük արժեք շուշավորումի մատրից (համապատասխանում է 0.5~2.5մ² սահմանների հավաքածախաղացիներին)

▶ Հաստատուն ցավի մոդուլ համարյալ էլեկտրասանցեսական ցանցի տատանումներից պաշտպանության (±15% լարում)

Material Type:

Երկաթ/ալյումինիում& ployուրեթան բժիշկական սակագիր

Կարբոնային վառ սիլիկոն & հակաստատիկ վառցալիք

Պլաստմասներ և TPE կշռվող սուգ

Նորական տեխնոլոգիա:

▶ lowes temperature resistance: -30℃ ցուրտի հանձնաժամանակ (ֆլուորոպլաստ նյութ)

▶ zelf-cleaning edge: դրանք փոխանցման և կպչումը (2 ժամ CIP-ի ժամանակի խանգիրություն օրական)

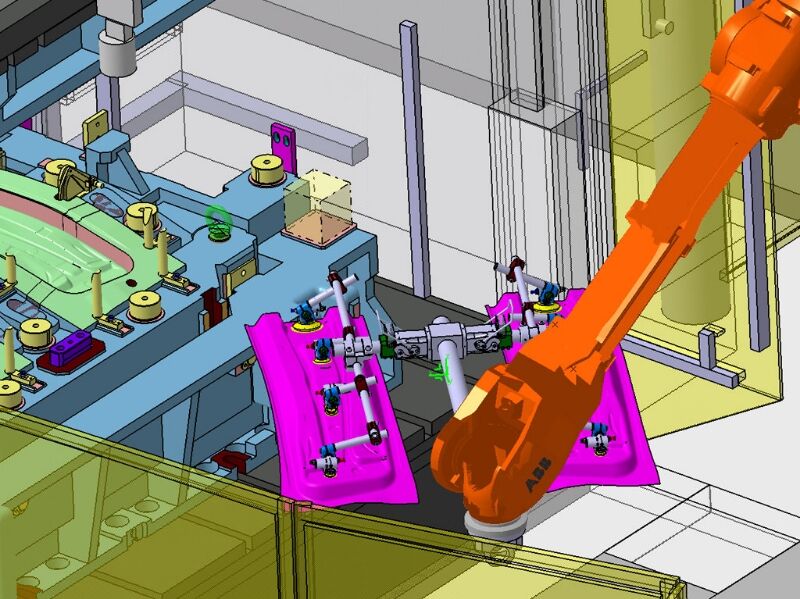

4. Assembly line: flexible component docking

Կամայական գործարքի հիմնական խնդիրը:

Երբ SUV/սեդան գետնվում է միևնույն գծում, պատուհանի տեղադրման սխալի տauxնությունը >8%-ն է։

Դաստավետ լուծում:

3D տեսական հղումով սուգ գնդակ՝ ճանաչելով տարբեր մոդելների առաջին դիմադրություններ (0.3 վայրկյան/հատ):

Նորոգն կառավարող համաձայնության համակարգ՝ փանջի տեղադրման կոնտակտային ուժը ≤5N-ն է (հեռացնելով սեղմող շղթաների ձգվելը):

Գլոբալ դեպքեր՝

Volkswagen MEB պլատֆորմ՝ սյունակային համակարգը թույլ է տալիս անընդհատ փոխել 10 մոդելները:

Թայլանդի Toyota գործkedան՝ գործունեության վերադարձնելու ժամկետը ընդունելու միացումը միայն 14 ամիս է: