Suzhou Shuowei Automation Technology Co., Ltd. presenta ventosas integradas de vacío de 200 mm de ancho: paletizado resistente sin rayones para cajas, madera y vidrio

Time: 2025-08-23

Suzhou Shuowei Automation Technology Co., Ltd. presenta ventosas integradas de vacío de 200 mm de ancho: paletizado resistente sin rayones para cajas, madera y vidrio

Fecha : 12 de noviembre de 2025

Ubicación : Suzhou Shuowei Automation Technology Co., Ltd., líder global en soluciones de manipulación de automatización industrial, lanzó hoy su esperada ventosas de Vacío Integradas de 200 mm de Ancho —una herramienta revolucionaria diseñada para resolver los desafíos más apremiantes en la manipulación de materiales pesados: piezas rayadas, succión inestable en superficies rugosas e instalación complicada del equipo.

Ubicación : Suzhou Shuowei Automation Technology Co., Ltd., líder global en soluciones de manipulación de automatización industrial, lanzó hoy su esperada ventosas de Vacío Integradas de 200 mm de Ancho —una herramienta revolucionaria diseñada para resolver los desafíos más apremiantes en la manipulación de materiales pesados: piezas rayadas, succión inestable en superficies rugosas e instalación complicada del equipo.

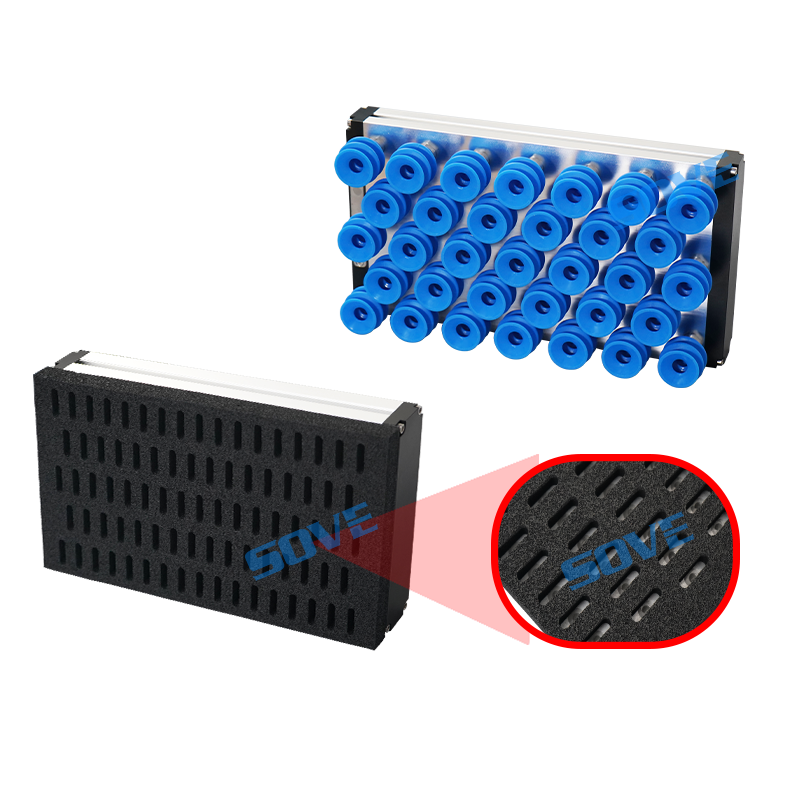

Diseñado para los sectores de logística, embalaje y fabricación, el nuevo ventosa integra en una matriz de 200 mm de ancho un silicón de alto rendimiento importado, esponja de sellado suave y una aleación de aluminio ligera. Ofrece un manejo sin rayones para cargas pesadas (hasta 50 kg por unidad), adaptándose a superficies irregulares y ásperas como cajas de cartón ondulado, tableros de madera y paneles de vidrio, cubriendo una brecha crítica en las soluciones tradicionales de paletizado.

Resolviendo los Costos Elevados en el Paletizado Industrial

Las ventosas de vacío tradicionales para manejo pesado suelen fallar en tres aspectos clave:

- Superficies Rayadas : Las ventosas rígidas de caucho o de silicón de baja calidad dejan marcas en las cajas (dañando la imagen de marca) o en el vidrio (haciendo los productos defectuosos), causando tasas de desperdicio del 5 al 8% en las líneas de embalaje.

- Sellado Deficiente en Superficies Ásperas : Tableros de madera irregulares o corrugados (cartones) provocan fugas de aire, obligando a los operadores a reducir la capacidad de carga o arriesgarse a perder mercancía, lo que cuesta más de $12,000 anualmente en inventario dañado.

- Diseños Voluminosos y Difíciles de Instalar : Marcos pesados de acero requieren de 2 a 3 trabajadores para su instalación y reposición, añadiendo más de 45 minutos de tiempo de inactividad por cada cambio de línea.

“Un importante cliente de logística de comercio electrónico nos comentó que estaban descartando el 7% de los cartones de marca debido a marcas de succión de ventosas, y sus líneas de palets de madera perdían 2 horas semanales por reposición de equipos”, dijo el gerente de producto de Suzhou Shuowei Automation Technology Co., Ltd. “La ventosa de succión integrada de 200 mm de ancho fue diseñada específicamente para eliminar estas frustraciones sin comprometer la capacidad de carga.”

Innovaciones Clave: 4 Características Principales que Impulsan el Rendimiento

1. Silicona Importada Resistente a Altas Temperaturas: Manipulado Sin Rayones y Estable Químicamente

En el corazón de la ventosa se encuentra la silicona importada grado alimenticio (Dureza Shore A 35), diseñada para soportar exigencias industriales:

- Tolerancia a Temperaturas Extremas : Soporta temperaturas de -40℃ a 200℃, lo que lo hace adecuado para embalaje de cadena fría (cartones de alimentos congelados) y procesos a alta temperatura (procesamiento posterior de vidrio al recocido).

- Estabilidad química : Resiste aceites, adhesivos y detergentes de embalaje, sin contaminación ni degradación del material, incluso después de 12 meses de uso diario (crítico para líneas de embalaje de alimentos/bebidas).

- Garantía Libre de Rayones : Se adapta a superficies lisas (como el vidrio) y cartones impresos sin aplicar presión excesiva, reduciendo al mínimo los desperdicios estéticos.

“En pruebas con un cliente de bebidas, los vasos de silicona manejaron 10.000 cartones impresos sin rayones, en comparación con 680 unidades dañadas con sus viejos vasos de goma”, señaló.

2. Esponja de Sellado Suave: Adaptabilidad Insuperable para Piezas Irregulares/Desiguales

Para resolver fugas de aire en superficies rugosas, la ventosa incluye una esponja de sellado suave de alta densidad (de 20 mm de espesor) con dos ventajas clave:

- Elasticidad Superior : Vuelve a su forma original en 0,1 segundos después de la compresión, manteniendo un sellado hermético en cajas onduladas (con crestas superficiales de 3 mm) y tableros de madera (con irregularidades de veta).

- Compatibilidad con Superficies Rugosas : Se adapta a piezas de trabajo con irregularidades superficiales de hasta 5 mm, eliminando la necesidad de alisar manualmente la superficie (un paso que añadía 15 segundos por paleta para nuestros clientes).

Un fabricante de muebles que probó el producto informó una reducción del 92% en paneles de madera caídos, gracias al rendimiento de sellado de la esponja. "Antes evitábamos manejar madera con nudos con ventosas; ahora es nuestro método preferido", afirmó [Mark Taylor], Director de Logística de la empresa.

3. Aleación de Aluminio Ecológica Liviana: Fácil Instalación, Larga Durabilidad

El marco de la ventosa está fabricado en aleación de aluminio ecológica 6061-T6 de alta resistencia , resolviendo los problemas de volumen y corrosión de los diseños tradicionales de acero:

- Reducción de peso : Con solo 3,2 kg (modelo de 200 mm de ancho), es un 40 % más ligero que las alternativas de acero, un trabajador puede instalarlo o reposicionarlo en 10 minutos (frente a 45 minutos en el caso de copas de acero).

- Resistencia a la corrosión : El tratamiento superficial anodizado resiste la humedad (fundamental para el almacenamiento en palets de madera) y productos químicos industriales, prolongando su vida útil hasta más de 8 años (el doble de los 4 años promedio de las copas de acero).

- Estabilidad estructural : Soporta hasta 50 kg por unidad sin deformarse, incluso durante operaciones continuas las 24 horas (probado más de 10.000 ciclos sin deformación).

4. Diseño Matricial de 200 mm de Ancho: Versatilidad en 4 Escenarios Clave de Manipulación

La disposición matricial de 200 mm de ancho de copas y esponja garantiza compatibilidad con las piezas más comunes de uso intensivo:

- Paletizado de Cajas : Cubre tamaños estándar de cajas (300x200 mm a 600x400 mm) en una sola toma, ideal para centros de cumplimiento de comercio electrónico y retail.

- Manipulación de Madera : Sella alrededor de nudos y veta en tableros de madera de 18 mm a 50 mm de espesor, utilizados en logística de materiales para muebles y construcción.

- Manipulación de Vidrio : La silicona sin rayas protege paneles de vidrio de 3 mm a 12 mm (para ventanas, pantallas) durante el ensamblaje y el envío.

- Cargas pesadas : Combinado con una bomba de vacío (vendida por separado), puede manejar cargas de 50 kg, adecuado para embalaje de electrodomésticos (por ejemplo, cajas de lavadoras) y piezas industriales.

Disponibilidad Global y Personalización

Las ventosas de succión integradas de 200 mm de ancho ya están disponibles para pedido global, con dos modelos estándar:

- Modelo VAC-200S : Optimizado para piezas delicadas (cajas, cajas de plástico) con almohadillas de silicona mejoradas.

- Modelo VAC-200H : Versión resistente para madera, vidrio y cargas de 50 kg, con estructura de aluminio reforzada.

Suzhou Shuowei Automation Technology Co., Ltd. también ofrece opciones personalizadas, incluyendo:

- Anchos personalizados (150 mm - 300 mm) para piezas no estándar.

- Adaptadores de compatibilidad para brazos robóticos (Fanuc, ABB, KUKA) y equipos de elevación manual.

- Actualizaciones para certificación en contacto con alimentos en líneas de envasado farmacéutico y alimentario.

Próximos Pasos para Fabricantes y Proveedores Logísticos

Para obtener más información sobre las Ventosas de Succión Integradas de 200 mm de ancho:

- Visite https://www.sove-tech.com/para ver modelos 3D, especificaciones técnicas y videos de pruebas.

- Solicite una demostración gratuita en sus instalaciones: [email protected]con su escenario de manipulado (por ejemplo, “paletizado de cartones, cargas de 30 kg”).

- Póngase en contacto con el equipo global de ventas en +86-18362520426para recibir presupuestos personalizados y plazos de entrega.

“El futuro del manipulado de alta resistencia no se trata solo de levantar más—se trata de levantar de forma más inteligente, sin desperdicio ni tiempos muertos,” dijo [Emma Carter]. “Este lanzamiento es nuestra promesa de ayudar a los fabricantes a convertir el manejo de materiales de un centro de costos en un impulsor de eficiencia.”

Acerca de Suzhou Shuowei Automation Technology Co., Ltd.

Suzhou Shuowei Automation Technology Co., Ltd. diseña y fabrica soluciones de automatización y manipulación de precisión para industrias como logística, empaquetado, automotriz y bienes de consumo. Con más de 15 años de experiencia, los productos de la empresa son utilizados por más de 2.000 clientes en 50 países, brindando mejoras medibles en la reducción de desperdicios, eficiencia laboral y seguridad operativa.