GKS--Højpræcisionsgreb

Materialer

- Chukkelegeme i aluminiumslegering

- Kæber i aluminiumslegering

Implementering af standarder

- GB/T 15706-2012

- JS B 6336

- EN-GJS-500-7

- ATEX 2014/34/EU

- Produkudstillinger

- 3D-forhåndsvisning

- Beskrivelse

- Forespørgsel

- Relaterede produkter

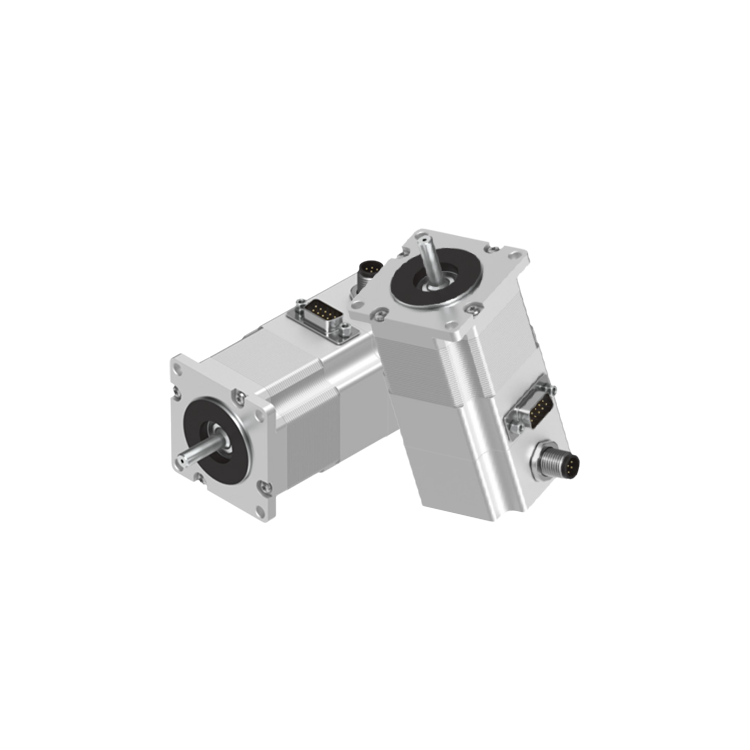

SOVE

Den højpræcise gripper benytter en multi-aksel koblet servodrive og har fremragende ydeevne inden for mikro-assembly. Dens fleksible cellemetamorfose mekanisme-design opnår ikke blot en gentagelsesnøjagtighed på ±0,5 μm, men er også dybt integreret i wafer-forudjustering, mikrolejer-montage og biochip-fikseringssystemer og kan fastholde en vinkelafvigelse på 0,01° under en kraftpåvirkning på 50 N.

Det anvendes omfattende i ⚙️ præcisionsdrejecentre til akseldelene i high-end CNC-bearbejdning, 🤖 flerleddede robot-samarbejdssystemer i intelligente produktionslinjer og 🛠️ femakse adaptive spændingsplatforme i skabelonengineering, hvilket gør det muligt at realisere samarbejdende innovation af proceskæder inden for avanceret produktion.

1. Om 3D-modeller og tekniske parametre:

"Hvis du ønsker at få det, bedes du kontakte os via e-mail."

2. Om prishenvielse:

"Hvis du ønsker at få det, bedes du kontakte os. Vi vil give den mest passende citatplan."

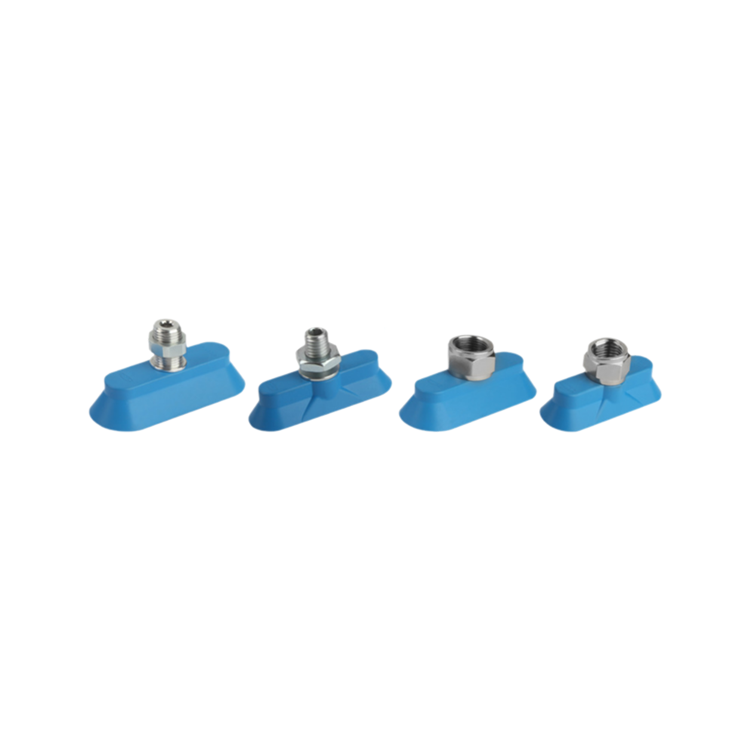

Beskrivelse

- Svartiden er hurtig.

- Spændvidden er justerbar

- Gentagelsespositionsnøjagtighed: ±0,01 mm.

- AR = Modstandsdygtighed mod afrinding

- OR=Oliefasthed

- IR=Impaktresistens